Discover Why High Pressure Roller Crusher Are So Popular?

2025-11-07The high-pressure roller crusher, also known as the high-pressure roller mill, is a high-pressure roller mill featuring a simple structure and reliable performance. It is capable of fine and ultra-fine crushing operations with controllable fineness modulus. 1. Why Choose . The hydraulic system facilitates easier and more effortless adjustment of roller gaps while safeguarding the entire machine’s safety. . The high-pressure roller mill employs Huashengming’s proprietary casting process, significantly extending roller surface lifespan to over 20,000 hours. . Steel roller surfaces deliver high economic efficiency in the pebble processing sector. 2. Applicable Materials Such as river pebbles, coke, coal, ceramic raw materials, quartz stone, limestone, mud shale, white chalk, bricks, furnace slag, clinker, feldspar, coke feldspar, gypsum, salt, chemical raw materials, and other solid materials. 3. Working Principle The core components of the high-pressure roller crusher are two counter-rotating rollers. Brittle materials are conveyed into a weighing bin equipped with load cells via feeding equipment. They then enter the feed mechanism of the roller press and are drawn into the gap between the two similarly sized, counter-rotating rollers. The rollers compress the material into a dense cake, which falls from the gap through the discharge chute and is transported…

Why Double Roll Crushers Are The Ideal Choice For Granite Crusher?

2025-11-06Granite crusher, has become the ideal choice for processing hard materials like granite into sand due to its high efficiency, precision, energy savings, high quality, and ease of maintenance. 1.Advantages: Hydraulic double-roll crushers offer high operational efficiency. Utilizing a hydraulic system to drive the rollers’ rotation and compression ensures a smoother, more efficient crushing process, significantly boosting production output. Low maintenance costs. The hydraulic system’s high stability and reliability minimize maintenance and upkeep expenses during operation, effectively reducing enterprise operating costs. Superior crushing results. The rotational and compressive forces exerted by the rollers ensure uniform stress distribution on raw materials during crushing. This produces more consistent, finely graded sand and gravel particles, enhancing product quality.

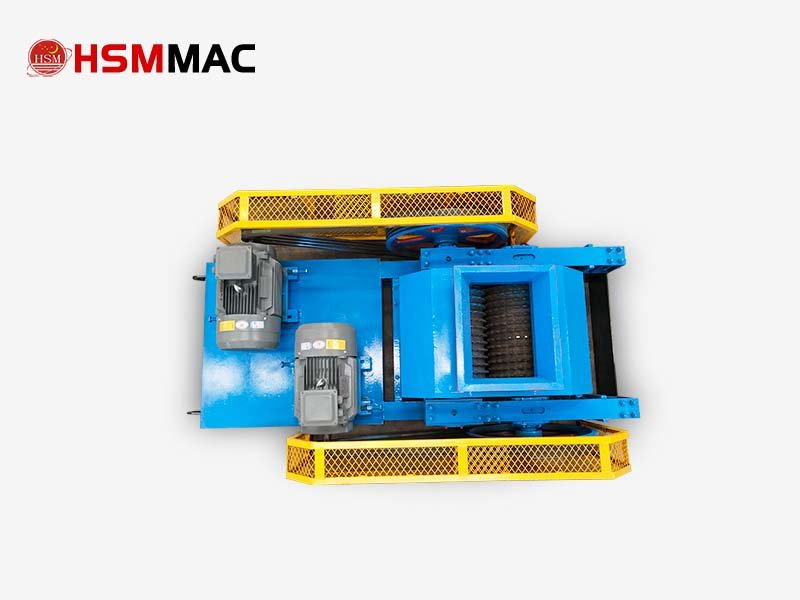

What Is The Working Principle Of Double Roller Crusher?

2025-11-04The double roller crusher, also known as the double-roller sand-making machine, can crush materials with compressive strengths up to 300 MPa. With a feed size ≤80 mm and fine output particle size, it delivers effective sand-making capabilities during operation. This excellent crushing and sand-making equipment is suitable for processing medium to high-hardness materials across various industrial sectors, earning widespread popularity among customers. It features outstanding performance and high production efficiency. It delivers substantial crushing force and simplified operation. Utilizing the double-roller crusher for high-yield processing enables efficient material utilization, generating significant economic and social benefits. It is widely employed for crushing river pebbles, calcite, quartz, glass, marble, bentonite, bluestone, steel slag, limestone, weathered sand, granite, basalt, and other materials. Many users are unfamiliar with the working principle and internal structure of double-roller crushers. Today, we provide a detailed explanation: 1.Working Principle The double roller crusher utilizes two independently driven roll shafts rotating in opposite directions to generate crushing forces through compression and abrasive shearing. Material enters through the feed opening and falls between the two rolls. After being crushed by the opposing rolls, the finished product naturally discharges. When encountering excessively hard or uncrushable material, the rollers automatically retreat via…

What Are The Advantages Of Hydraulic Crusher Machine?

2025-11-03Hydraulic Crusher Machine, also known as hydraulic double-roll crushers,represent an upgraded version of traditional spring-loaded double-roll crushers, utilizing hydraulic cylinders for pressure output. While conventional spring-loaded double-roll sand makers require manual spring pressure adjustment over extended use to meet finished product specifications, hydraulic CNC double-roll crushers feature automatic pressure regulation for precise compensation. Suitable for fine crushing operations with feed sizes ≤80mm, producing finished particles ranging from 50μm to 20mm. This equipment offers convenient, efficient, and flexible operation, producing uniformly sized particles while minimizing on-site dust pollution. It delivers outstanding performance with a compact footprint, simple adjustment of crushing ratios, and reliable operation. 1.Hydraulic Crusher Machine Feed Size: 25-100mm Production Capacity: 2-400 t/h Suitable Materials: Highways, high-speed railways, high-rise buildings, municipal projects, hydroelectric dam construction, concrete batching plants, sand and gravel yards, etc. Application Scope: River pebbles, calcite, quartzite, marble, cobblestones, bentonite, iron ore, bluestone, quarry rock, slag, limestone, weathered sand, diabase, granite, basalt, etc. 2.Working Principle The hydraulic crusher machine utilizes two independently driven roller shafts that rotate in opposite directions to generate crushing and grinding forces. Material enters through the feed opening and falls between the rollers, where it is crushed by the opposing rollers before naturally discharging….

How Effective Is Using A Double-Roll Crusher As An Ore Crusher?

2025-10-31The ore crusher, known as a double-roll crusher, utilizes two motors to drive two sets of rollers that compress and grind materials. It delivers superior crushing results compared to conventional crushing machinery, capable of processing various rock types with compressive strengths below 160 MPa. This equipment features low maintenance costs, minimal water consumption, stable performance, low power consumption, reduced dust generation, and low noise levels. 1. Ore Crusher Feed Size: 25-100mm Production Capacity: 2-400 t/h Suitable Materials: Highways, high-speed railways, high-rise buildings, municipal projects, hydroelectric dam construction, concrete mixing plants, sand and gravel yards, etc. Application Scope: River pebbles, calcite, quartzite, marble, cobblestones, bentonite, iron ore, bluestone, quarry rock, slag, limestone, weathered sand, diabase, granite, basalt, etc. 2.Working Principle The ore crusher utilizes two independently driven roller shafts that rotate in opposite directions to generate crushing and grinding forces. Material enters through the feed opening and falls between the rollers, where it is crushed by the opposing rollers before naturally discharging. When encountering excessively hard or uncrushable material, the rollers automatically retract via hydraulic cylinders or springs, increasing the gap between them. allowing the hard or uncrushable material to pass through unharmed. This mechanism safeguards the machine from damage. The feed…

How About Using A Double-Roll Crusher As An Iron Ore Crusher?

2025-10-29The iron ore crusher is a crushing equipment independently developed by our company, incorporating the advantages of all roller presses available in the integrated market. It is suitable for fine crushing operations with compressive strength below 160 MPa, moisture content under 30%,feed size less than 80 mm, and finished product size requirements of 0.5-20 mm. Widely applicable in industries such as cement, mining, metallurgy,and ceramics, it features reliable performance, high output, low power consumption, and excellent cost-effectiveness. 1.Iron Ore Crusher Feed Size: 25-100mm Production Capacity: 2-400 t/h Suitable Materials Highways, high-speed railways, high-rise buildings, municipal projects, hydroelectric dam construction, concrete mixing plants, sand and gravel quarries, etc. Application Scope River pebbles, calcite, quartzite, marble, cobblestones, bentonite, iron ore, bluestone, quarry rock, slag, limestone, weathered sand, diabase, granite, basalt, etc. 2.Configuration Comparison 3.Working Principle The iron ore crusher performs crushing operations via roller wheels. Material enters between the rollers through the feed opening and is crushed by compression. A fixed gap exists between the two rollers. Increasing this gap produces larger discharge particle sizes, while compressing the gap with tension springs reduces the discharge particle size. By adjusting the gap, the discharge particle size can be precisely controlled. 4.Performance Advantages 1 Simple…

What Is A Rock Crushing Machine Called?

2025-10-22What is a rock crushing machine called? Huashengming rock crushers, known as double-roll crushers, have become the cost-effective choice for small and medium-sized sand and gravel plants due to their compact structure, excellent finished particle shape, and low maintenance costs. Users can select spring or hydraulic models based on production capacity requirements and flexibly customize configurations. 1. Huashengming Crusher Model: Double Roll Crusher The double roll crusher is Huashengming’s flagship product. It crushes materials by squeezing them between two counter-rotating rollers, making it ideal for medium-hard materials (such as limestone, coal gangue, bluestone, etc.) in medium-fine crushing operations. It offers the following advantages: Compact structure, energy-efficient and high-yield Rollers feature thickened liners for extended service life (average sleeve lifespan exceeds 1 year), low over-crushing rates, and produce well-rounded sand particles with optimal gradation. Intelligent Upgrades Hydraulic systems support one-button start/stop, with select models (e.g., large flagship series) incorporating CNC technology for user-friendly operation and low maintenance costs. Eco-Friendly & Energy-Efficient Superior dust and noise control compared to impact crushers, meeting green production standards. Summary Huashengming Crushers’ double-roll crushers have become the cost-effective choice for small and medium-sized sand and gravel plants, thanks to their compact structure, excellent finished particle shape,…

What Is The Working Principle Of A Double Roller Crusher?

2025-10-21What is the working principle of a double roller crusher?The working principle of a double roller crusher (also known as a twin roller crusher) relies on the crushing force generated by the relative rotation of two rollers, which produces both compressive and shear forces to break down materials. Its core mechanism can be summarized as a process of “compression-grinding-controlled particle size.” 1. Core Crushing Mechanism Material Entrapping and Compression Material falls from the feed inlet between the two rollers and is drawn into the crushing chamber by the friction generated as the rollers rotate. The fixed roller and movable roller rotate at low speeds in opposite directions (typically with a linear surface speed < 4 m/s), applying high-pressure compression to the material, causing it to fracture. Manner of Crushing Force Application Compression Dominant: Smooth roll surfaces (standard in Huashengming models) primarily rely on compression to induce internal fractures and fragmentation, suitable for medium-hard materials (e.g., river pebbles, iron ore). Shear Force Augmented: Toothed roll designs (e.g., Huashengming double-toothed roll models) enhance splitting and tearing effects, ideal for cohesive materials (e.g., coal, clay). Discharge Control Crushed material discharges through the gap between the two rollers under gravity. Gap size directly determines…

What Are The Applications Of Small Glass Crushers In The Environmental Protection Industry?

2025-10-17Huashengming Small Glass Crusher achieves “turning waste into treasure” in the environmental protection industry through efficient crushing, resource recycling, and pollution control. Its equipment combines economic efficiency with environmental sustainability, making it particularly suitable for small and medium-sized recycling enterprises, restaurant chains, and building materials processing plants. It helps users reduce processing costs while pioneering green profit models. 1.Small Glass Crusher Waste Glass Recycling and Resource Utilization Crushing Process: Huashengming double-tooth roller crushers utilize compression and shearing forces to break down waste glass (such as wine bottles, medicine bottles, and flat glass scraps) into uniform particles (typically 2-10mm). The crushed glass particles can be directly used in recycled glass products (e.g., glass fiber, building materials) or as industrial additives, reducing reliance on virgin resources. Economic Benefits: With sufficient raw materials, glass particle processing projects feature a short payback period (approximately six months). The high market value of crushed glass particles enables users to achieve annual revenues of hundreds of thousands of yuan through resource recovery. 2. Small Glass Crusher Environmental Treatment and Pollution Control Dust and Noise Control: Huashengming equipment incorporates sealed chambers and dust collection systems (e.g., pulse jet dust collectors) to effectively suppress dust dispersion during crushing, minimizing…

What Is The Difference Between Roll Crusher And Sizer?

2025-10-10What is the difference between roll crusher and sizer?Roll crushers and classifiers are two distinct types of equipment with different functions in mining, building materials, and other industries. Their core differences lie in their working principles, application scenarios, and product objectives. As a professional manufacturer of crushing equipment, Huashengming excels in the field of crushing with its roll crushers, while its classifiers are primarily used for particle size separation. 1. Core Functionality and Working Principle Comparison Comparison Dimensions Roller Crusher Classifier (e.g., spiral classifier) Core Functions Material Crushing: Grinds large chunks into target particle size through compression and shear forces Particle size classification: Separates crushed material by particle size (coarse/fine particle separation) Working Principle Dual rollers rotate in opposite directions, subjecting material to compression, splitting, or shear crushing Based on differences in particle settling velocity in liquid, coarse particles settle to the bottom while fine particles overflow Operating Modes Dry crushing (no liquid medium required) Wet operation (requires water or slurry medium) Particle Size Control Adjustable roll gap (1–20mm) controls output particle size Controls classification size by adjusting screw rotation speed and overflow weir height Typical Application Scenarios Crushing raw coal, ore, construction waste, etc. Forming a closed-circuit system with…

What Is A Four-Roll Crusher?

2025-10-09What is a four-roll crusher? The roller crusher (also known as a double-roll crusher or twin-roll crusher) is a mechanical device that utilizes two counter-rotating rollers to crush materials through compression, grinding, or splitting. It is primarily used for medium and fine crushing of materials of medium hardness or below, such as coal, limestone, and ores. 1. Definition and Core Principles of Roller Crushers Working Principle Material enters through the feed opening and falls between two rollers. Driven by the friction generated from the rotating rollers, it is drawn into the crushing chamber where it is broken down through compression, shearing, or splitting forces. The discharge particle size is controlled by adjusting the gap between the two rollers (1–20 mm); a larger gap produces coarser output. Overload Protection: When hard objects enter, springs or hydraulic systems retract the movable roll to widen the gap, expelling foreign matter before automatically resetting. Drive Configuration: Dual motors drive the two rolls in opposite directions via belts or gears. Traditional models use long-tooth gears to accommodate varying roll distances. Roller Surface Types and Applications Smooth Rollers: Primarily for compression grinding, suitable for fine crushing of medium-hard materials (e.g., limestone, cement clinker). Toothed/Grooved Rollers: Enhance…

What Are The Models Of Small Electric Rock Crushers?

2025-10-07Huashengming Small Electric Rock Crusher Featuring dual-roll (precision particle size), jaw (large-block coarse crushing), and dual-stage (wet material specialist) core technologies, it covers applications including sand and gravel fine crushing, construction waste recycling, and tailings processing: 1. Core Product Series and Model Specifications Double-roll Crusher (Flagship Model) Achieves precise sand production through dual-roll compression (adjustable particle size 1-50mm), with under-crushing rate <10%. Suitable for fine crushing of medium-hard rock. Model Processing Capacity (t/h) Output Particle Size (mm) Motor Power (kW) Application Scenarios 2PGT400×250 2–10 1–3 7.5×2 Construction Waste Recycling, Gold Mine Test Mining 2PGT400×400 5–12 1–5 11×2 Small-Scale Sand Plant, Limestone Sand Production 2PGT610×400 5–20 2–8 15×2 Coal Crushing, Quartzite Fine Crushing Technical Highlights: Roll shells feature a high-chromium manganese steel + rare metal composite layer (triple-layer structure), with a lifespan exceeding 2 years (processing capacity > 30,000 tons); Spring-adjustable roll gap (±1mm precision) enables granularity fine-tuning. Jaw Crusher (Preferred for Primary Crushing) Processes large rock blocks (feed ≤340mm), featuring simple structure and low maintenance costs. Model Processing Capacity (t/h) Maximum Feed Size (mm) Motor Power (kW) PE-150×250 1.2–3.5 125 5.5 PE-250×750 5 210 15 Suitable Applications: Laboratory coarse crushing, small-scale quarries (e.g., primary crushing in gold…