The high-pressure roller crusher, also known as the high-pressure roller mill, is a high-pressure roller mill featuring a simple structure and reliable performance. It is capable of fine and ultra-fine crushing operations with controllable fineness modulus.

High Pressure Roller Crusher

1. Why Choose

. The hydraulic system facilitates easier and more effortless adjustment of roller gaps while safeguarding the entire machine’s safety.

. The high-pressure roller mill employs Huashengming’s proprietary casting process, significantly extending roller surface lifespan to over 20,000 hours.

. Steel roller surfaces deliver high economic efficiency in the pebble processing sector.

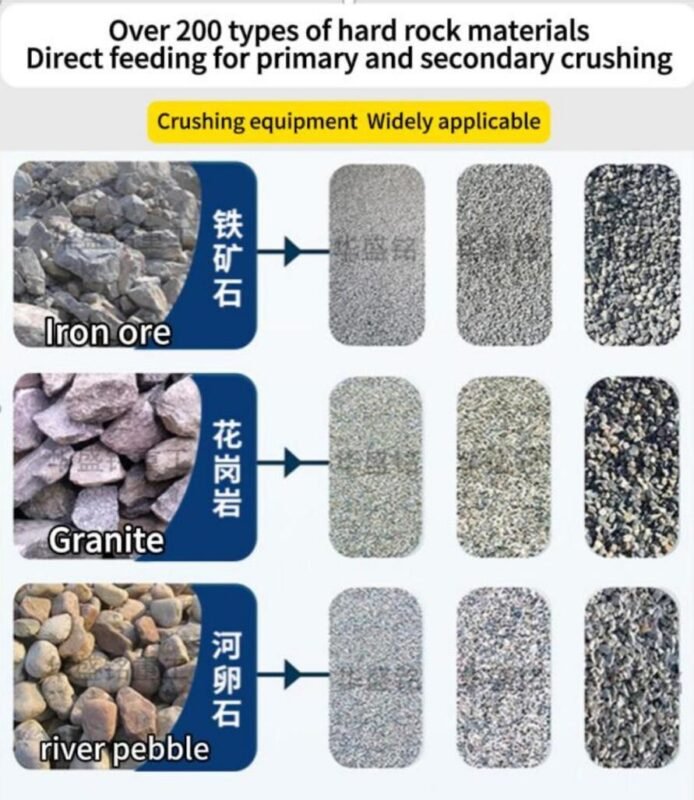

2. Applicable Materials

Such as river pebbles, coke, coal, ceramic raw materials, quartz stone, limestone, mud shale, white chalk, bricks, furnace slag, clinker, feldspar, coke feldspar, gypsum, salt, chemical raw materials, and other solid materials.

3. Working Principle

The core components of the high-pressure roller crusher are two counter-rotating rollers. Brittle materials are conveyed into a weighing bin equipped with load cells via feeding equipment. They then enter the feed mechanism of the roller press and are drawn into the gap between the two similarly sized, counter-rotating rollers. The rollers compress the material into a dense cake, which falls from the gap through the discharge chute and is transported out by conveying equipment. The material cakes undergo further dispersion or grinding in subsequent processes.

High-pressure roller mills are categorized into large, medium, and small sizes based on model specifications.

. Models G100x60 and G120x80, with hourly capacities of approximately 60-310 tons, are classified as small high-pressure roller mills.

. Models G140x100 and G180x150, with hourly capacities of 310-1180 tons, are classified as large high-pressure roller mills.

Equipment configurations are available in three types: high-spec, standard-spec, and low-spec.

4. Performance Advantages

Simple and lightweight with powerful crushing force

High efficiency, low energy consumption, and superior output quality

Wide applicability and extended service life

Intelligent control for energy savings and labor reduction