How Does A Gold Rock Crusher Work?

2025-10-05Huashengming Gold Rock Crusher (primarily a roller crusher) operates on the principle of dual-roller compression crushing combined with shear tensile action. Hydraulic or mechanical adjustment precisely controls the discharge particle size (1-50mm), making it particularly suitable for crushing high-hardness or high-moisture sticky materials such as muddy gold ore and granite. 1. Core Crushing Principle Synergistic Action of Compression and Shearing Upon entering the gap between the two rollers, the material undergoes dual forces: high-pressure compression and serrated shearing: Compression Crushing: The two rollers rotate in opposite directions (with a designed speed differential), applying sustained high pressure to the material, causing the rock to fracture along its weak joints. Shear Tension: The serrated roller surfaces (e.g., wolf teeth, wave teeth) enhance shear forces on the material. This is particularly effective for sticky particles in muddy gold ore, where tension strips away the clay layers enveloping gold grains. This synergistic action significantly reduces over-crushing rates (<10%) and improves gold ore leaching efficiency. Simultaneous Particle Size Classification Certain models (e.g., high-efficiency classification crushers) incorporate direct screening through inter-tooth gaps during crushing. Qualified particles are rapidly discharged, while oversized particles are returned for re-crushing, preventing pulverization from repeated crushing. 2. Particle Size Control Mechanisms…

Performance Comparison of Different Models of Quarry Rock Crushers

2025-10-041. Quarry Rock Crushers Analysis of Various Crusher Types Double Roll Crusher: The Preferred Choice for Precision Sand Production Working Principle: Double-roll compression crushing with hydraulic/spring-loaded roll gap adjustment (±0.1mm precision), under-crushing rate <10%. Wear Resistance: Roll shells feature high-chromium manganese steel + rare metal composite layers (triple-layer structure), lifespan >2 years (processing capacity exceeding 30,000 tons). Application Scenarios: Small-scale sites: 250×400 model (¥25,000+), 2-10 t/h output, 1-3mm fine sand, ideal for construction waste recycling. Large-scale sites: 1500×1000 model (¥380,000+), 400 t/h output, AI hydraulic control, produces well-shaped sand from hard rock. Double-Tooth Roller Crusher: Wet & Sticky Material Specialist Anti-Blocking Design: Serrated roller surfaces (wolf teeth/wave teeth) enhance gripping force, enabling direct crushing of materials with up to 15% moisture content and near-zero blockage rate. Flexibility: Adjustable roll gap (1-20mm) delivers wide output size range (10-200mm). Representative Models: 2PGC400×400: 15-30 t/h capacity, ideal for crushing clayey gold ore and coal. 2PGC1200×1500: 200-300 t/h capacity, 800-1050mm feed size, primary crushing for large mining sites. Jaw Crusher: Primary Crushing of Large Hard Rock Crush Capacity: Feed size ≤1020mm (e.g., PE-1200×1500), high crushing ratio (1:10). Structural Advantages: Simple and reliable design, low maintenance costs, suitable for mobile production line integration. Cost-Effectiveness: Small-scale…

What Are The Latest Technologies For Mini Crusher Machine ?

2025-09-29Huashengming mini crusher machine focus on four key areas of technological innovation: wear resistance, intelligent operation, wet material adaptability, and environmental efficiency. Integrating these advancements with core products (such as double-roll crushers and two-stage crushers), the latest breakthroughs include: 1. Wear-Resistant Technology Innovation: Extended Lifespan, Reduced Maintenance Costs Composite Roller Shell/Hammerhead Casting Process Three-layer structural design: Outer layer of high-chromium alloy (hardness HRC60+, 50% improved impact resistance), middle layer of high-manganese steel matrix (water quenching prevents cracking), bottom layer with dovetail groove locking mechanism to prevent detachment. Measured service life improvement: Roller skin lifespan reaches 2-3 years (compared to 6-12 months for standard equipment), with 67% reduced wear when processing granite. Annual replacement frequency drops from 6 times to 2 times. Material Innovation High-chromium manganese steel + rare metal composite material. Through optimized tungsten carbide particle distribution and heat treatment processes, wear resistance is increased by 200%, suitable for hard rock scenarios like high-silica ores. 2. Wet Material Processing Technology: Overcomes clogging issues with high-moisture, sticky materials Dual-stage screenless crushing design Two-stage rotor crushing: Upper rotor performs coarse crushing of wet coal/viscous materials, while lower rotor refines to ≤3mm. Screenless structure completely eliminates clogging. Shift gap adjustment technology: Automatically adjusts…

What Are The Models Of Industrial Rock Crushers?

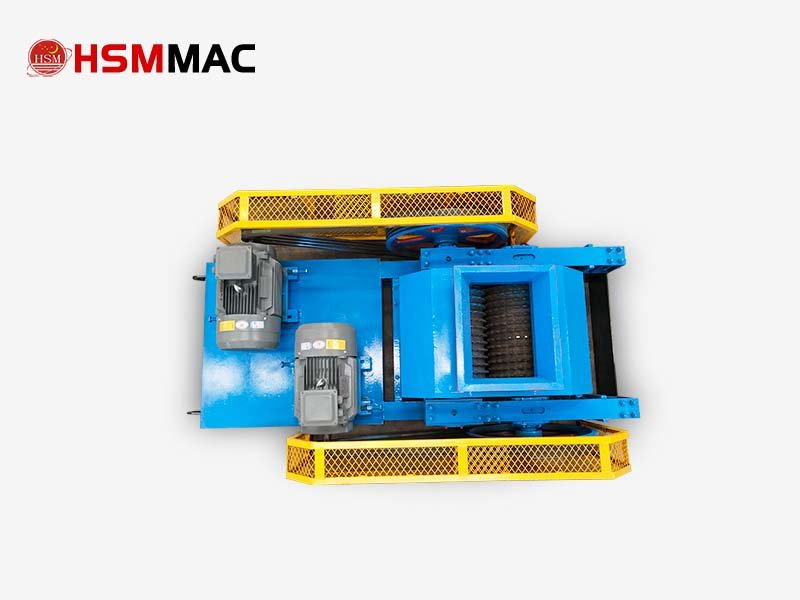

2025-09-20Huashengming Heavy Industry’s industrial rock crushers feature high efficiency, wear resistance, intelligent control, and multi-scenario adaptability as core advantages, widely applied in mining, building materials, and construction aggregate production sectors. 1. Core Product Series and Model Specifications Huashengming’s industrial rock crushers primarily comprise three major series: double-roll crushers, double-stage crushers, and jaw crushers, covering the entire process from coarse crushing to fine crushing: Double-Roll Crusher Series Featuring high-precision particle size control and energy efficiency, ideal for fine crushing of medium-hard rocks (e.g., granite, basalt): Compact Portable Models 2PGT400×250: Capacity 2-20 t/h, roller diameter 400mm, motor power 22kW, weight approx. 3.8 tons. Tire chassis design, ideal for construction waste fine crushing. 2PGT400×400: Capacity 5-12 t/h, discharge size 1-5 mm (hydraulically adjustable), supports diesel generator power supply. Medium-Sized High-Efficiency Models 2PGY800×600: Capacity 20-80 t/h, intelligent hydraulic system for particle size adjustment, dual motor drive (45kW+55kW), suitable for combined sand and gravel operations. Large Flagship Models 2PGY1200×1000: Capacity 90-100 t/h, roller diameter 1200mm, dual motors 150kW, adjustable granite crushing size to 1-5mm. 2PGY1500×1000: Capacity 120-200 t/h, dual motors 264kW (2×132kW), specifically designed for large aggregate production lines. Two-stage Crusher Series Specialized for high-hardness rocks (e.g., granite, silicate rock) and wet, sticky materials. Screenless…

Do You Need A High-Performance Aggregate Crusher?

2025-09-19Huashengming aggregate crushers leverage modular design (portable/fixed), patented wear-resistant technology, and intelligent energy-saving control as their core competitive strengths, excelling particularly in processing hard materials such as granite and construction waste. 1. Core Product Series and Technical Advantages Wear Resistance and Durability Roll shells utilize high-chromium manganese steel + rare metal composite material (patented technology), achieving HRC62 hardness with a service life exceeding 2 years. Large equipment (e.g., 1510 hydraulic double-roll crusher) features wolf-tooth roll design, enhancing hard rock engagement capability and reducing material jamming. High Efficiency and Energy Savings Dual Motor Drive: Achieves 20%-45% energy savings (e.g., 2PGC400×250 consumes only 22kW while producing 5-12t/h). Intelligent Hydraulic System: Enables stepless adjustment of discharge particle size (1-20mm), low over-crushing rate, and well-rounded finished particle shape. Flexible Mobility Portable models (e.g., 2PGC400×250) feature tire chassis with weight ≤3.8 tons, compatible with diesel generator power supply, ideal for temporary sites and remote operations. Environmental Safety Enclosed structure + integrated dust collection system ensures compliant dust emissions; hydraulic spring overload protection minimizes failure rates. 2. Application Scenarios and Materials Suitable Materials: Hard rock: Granite (compressive strength ≤160MPa), basalt, river pebbles; Medium-hard materials: Limestone, bluestone, construction waste; Special materials: Wet coal lumps, coke, fertilizer raw…

What Are The Applications Of Mobile Rock Crusher?

2025-09-16Mobile rock crusher play a vital role in mining, construction, metallurgy, chemical processing, and other industries due to their high efficiency, energy savings, and environmental friendliness. They are particularly suited for scenarios requiring flexible mobility and on-site crushing. Their core advantages lie in reducing logistics costs, enhancing crushing efficiency, and adapting to diverse material requirements. As highly efficient and flexible crushing equipment, mobile rock crushers are widely used across multiple sectors, primarily for the following applications: 1. Mining Ore Crushing Suitable for crushing medium-hardness minerals such as iron ore, quartzite, potassium feldspar, limestone, river pebbles, basalt, and granite. Particularly effective for low-grade iron ore with extremely fine grain sizes. Through repeated crushing and grinding, the ore is reduced to fine particles or powder, facilitating subsequent mineral processing. 2. Construction Waste Recycling and Aggregate Production Used for crushing and recycling construction waste, reducing landfill disposal while producing recycled aggregates for construction, roadworks, and similar projects. The finished sand and gravel exhibit excellent particle shape with minimal needle and flake content, making them suitable for high-quality aggregate applications such as highways, railways, and bridge construction. 3. Building Materials and Metallurgical Industries Widely applied in brick factories, ceramic plants, and steel mills for…

What Are The Core Advantages Of Mobile Concrete Crushers?

2025-09-15Huashengming Mobile Concrete Crusher leverages its core strengths of modular mobility, efficient resource processing (especially construction waste), and eco-friendly low consumption. It is ideal for projects requiring frequent relocation or on-site processing of waste concrete. 1. Product Types and Technical Features Mobile Double-Roller Crusher Model Example: 2PGY800×600 (Export model for Georgia). Technical Highlights: Fully hydraulic drive with high automation for simplified operation. Feed size ≤5cm, discharge size ≤8mm, ideal for crushing fine brick-making raw materials. Modular design enables flexible mobility and adapts to diverse operational scenarios. Mobile Double-Stage Crusher Applicable Materials: Concrete blocks, waste bricks/tiles, coal gangue, and other dry/wet materials. Working Principle: Dual-rotor two-stage crushing (primary + secondary crushing) enhances efficiency through “hammer-crushing + material-on-material impact” self-collision mechanism. Screenless design prevents wet material blockage, with processing capacity of 50-400 t/h. Mobile Construction Waste Crusher Core Features: Integrated rebar removal system prevents host blockage by separating steel bars from aggregates. Transforms traditional three-stage crushing into single-stage processing, simplifying workflow with uniform output particle shape (polygonal rate ≥95%). Capacity: 20-700 t/h. Supports track/tire mobility to reduce material transportation costs. Mobile Heavy Hammer Sand Maker Economic Advantages: Features a heavy hammer crusher as the main unit, delivering high crushing ratios and producing…

Which Type Of Asphalt Crusher Is Best To Choose?

2025-09-13Which type of asphalt crusher is best to choose? Asphalt crushing achieves remarkable results with asphalt tooth roller crusher, whose advantages are primarily reflected in the following aspects: 1. Precise particle size control and uniform output By adjusting the roller tooth gap (typically adjustable between 5-30mm), the asphalt tooth roller crusher precisely controls output particle size. This ensures uniform particle size of the crushed asphalt aggregate, meeting the gradation requirements for recycled mix. The crushed asphalt can be directly used in plant-mixed hot recycling, with the blending ratio increased to 45%, while maintaining road performance that meets specification standards. Additionally, its shear crushing principle avoids the over-crushing issues common in traditional equipment (such as jaw or hammer crushers), resulting in a needle and flake particle content below 10% and low fines production. 2. High efficiency and energy savings, low operating costs The asphalt tooth roller crusher employs a low-pressure crushing principle, reducing energy consumption by over 30% compared to traditional equipment. Its multi-tooth synergistic action distributes crushing pressure, making it suitable for continuous operation with an hourly processing capacity of 50-200 tons (depending on model). Simultaneously, the enclosed structure and dust collection system design keep dust emission concentrations below 20mg/m³,…

How About Choosing Roll Crusher For Gold Ore Crusher?

2025-08-26choose roll crusher (especially full hydraulic or high pressure roll mill model) has significant advantages, especially in energy saving and consumption reduction, particle size control and recovery rate enhancement outstanding performance. The following is a comprehensive analysis and selection recommendations: 1. Core advantages and application value of roll crusher for gold ore crushing High-efficiency dissociation and recovery rate improvement Microcracking effect: High-pressure roller mill generates microcracks inside the ore through hydrostatic pressure extrusion, which enhances the efficiency of subsequent cyanide leaching, and the gold recovery rate can be increased by 3-5 percentage points (e.g., the case is from 88.6% → 93.2%). Precise grain control: Hydraulic adjustment of roll spacing (0.1-40mm), stable discharge particle size of 5-10mm, avoiding over-crushing and reducing grinding energy consumption by 20%-30%. Energy saving and economy Optimisation of energy consumption: the unit power consumption is as low as 2.4kW-h/tonne, which is 25% more energy-saving than the traditional three-stage crushing (jaw + cone), and the annual electricity cost of large mines is over 18 million RMB. Low maintenance cost: high chrome alloy/tungsten carbide roll surface life of more than 10,000 hours, annual maintenance costs down 45%, modular design to shorten downtime. Strong adaptability Complex ore processing: the double-roll…

What Is A Mobile Roller Sand Making Machine?

2025-08-11Mobile roller sand making machine is a kind of mobile sand production equipment integrating crushing, screening and conveying functions, which is especially suitable for mobile operation scenarios (such as construction sites, mining temporary mining). 1. Core structure and working principle of Mobile Roller Sand Making Machine Modular integrated design The equipment integrates roll crusher, vibrating screen, feeder, conveyor belt and control system in one unit, equipped with wheeled or crawler chassis to support rapid transfer. Roll Crushing Principle Material is crushed by squeezing and shearing when passing through the gap of double rolls, and the roll surface can be customised to be flat rolls (fine-grained sand making) or toothed rolls (coarse crushing of medium-hard materials), and the discharge size is adjustable from 1-40mm. Intelligent control system is equipped with PLC automatic adjustment system, realising one-key start-stop, pressure adaptive anti-jamming, and some models support remote monitoring. 2. Core Advantages Flexibility and cost saving No infrastructure installation: directly stationed in the work site, eliminating the fixed production line infrastructure costs and material transport costs. Follow the mining surface movement: suitable for stage-by-stage projects (e.g. road construction), reducing equipment idling. High-efficiency sand making performance High yield: Roll crushing reduces over-crushing, and the finished…

What are the different types of roll crushers?

2025-07-31Roll crusher can be classified into various types according to the different roll surface structure, transmission mode, adjustment device and application scenarios. The following are the main classifications and characteristics: 1. Classification according to roll surface structure Double light roll crusher (flat roll type) Characteristics: Smooth roll surface, crushing materials through extrusion and grinding, uniform discharge size (usually 0.5-10mm). Applicable scenes: medium and fine crushing operation, such as limestone, river pebbles, cement clinker, construction waste and other materials with compressive strength ≤250MPa. Advantage: simple structure, less dust, low noise, suitable for sand making and fine crushing needs. Double Toothed Roll Crusher Features: roll surface with teeth (such as wolf teeth, ring teeth), through splitting and shear force crushing materials, both pre-screening function, reduce over-crushing. Applicable scenario: coarse and medium crushing operation, such as coal, coke, sinter ore and other brittle materials (compressive strength ≤ 160MPa), with feed size up to 1200mm. Advantage: Strong ability to deal with viscous materials, and the differential speed design prevents clogging. 2. Classified according to the transmission mode Triangle belt drive Low cost, easy maintenance, suitable for small equipment (such as 2-12 tonnes per hour). Coupling drive (hard link) High transmission efficiency, strong carrying capacity,…

What equipment to choose for stone sand making?

2025-07-22What equipment should be selected for stone crushing and sand making? The choice of equipment for stone crushing and sand making needs to be matched according to the characteristics of the material, the capacity demand and the requirements of the finished product. Roller sand making machine in the field of stone crushing and sand making by virtue of its unique working principle and structural design, showing significant comprehensive advantages, especially suitable for the sand making needs of materials below medium hardness (such as limestone, river pebbles, greenstone, etc.). The following is the analysis of its core advantages and applicable scenarios: 1. Core advantages of roller sand making machine Excellent granularity and reasonable grading of finished products Cubic grain shape: through the double-roll extrusion crushing (non-impact), the material breaks along the natural texture, and the finished sand is cubic, with low needles and flakes content, which improves the compressive strength of concrete. Precise and controllable particle size: Hydraulically or mechanically adjustable roll gap (0.5-50mm), uniform discharge particle size (1-10mm), and stable fineness modulus of 2.6-3.0 (construction sand class I standard). Low over-crushing rate: Extrusion crushing reduces the generation of stone powder (powder content ≤10%), continuous grading, directly used for concrete, masonry…