How Effective Is The Double-Roll Crusher Iron Copper Gold Ores Crusher?

2025-12-01Huashengming Double Roll Crusher (also known as iron copper gold ores crusher) is indeed a highly specialized and efficient piece of equipment for processing metal ores such as iron, copper, and gold. It is particularly well-suited for undertaking medium and fine crushing tasks in mineral processing workflows, capable of reducing ore to the desired particle size and preparing it for subsequent processes like ball milling. 1. Working Principle The Huashengming double-roll crusher operates on the principle of “material layer crushing.” Material is uniformly fed through the feeding device between two counter-rotating high-pressure rollers. Within the roller gap, the material forms a dense layer where particles mutually compress and grind each other, achieving highly efficient “material-on-material crushing.” Compared to impact crushing, this static pressure crushing method offers higher energy utilization and reduces over-crushing. The crushed material develops numerous micro-cracks internally, which greatly benefits subsequent ball milling processes by significantly enhancing grinding efficiency. 2. Advantages Significantly Enhances Subsequent Grinding Efficiency This represents one of its core values when processing iron ore. After being squeezed between its rollers, numerous micro-cracks form within the ore particles. This makes it easier for subsequent ball mills to grind them to the required fineness, substantially reducing ball…

Can A Double-Roll Crusher Be Used As A Lepidolite Crusher?

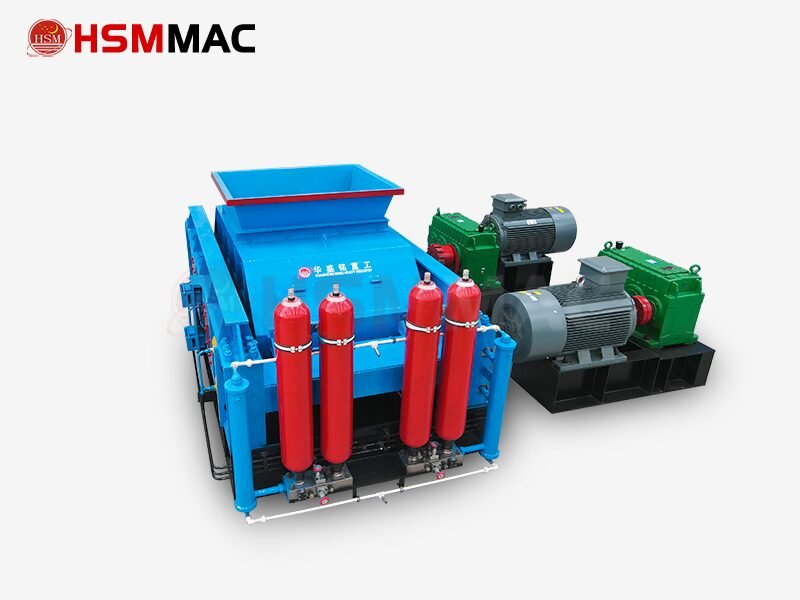

2025-11-29lepidolite crusher(also known as double-roll crusher), Huashengming double-roll crusher is a highly reliable and efficient choice for processing lithium mica ore. It is particularly suitable for the medium and fine crushing stages to produce uniformly sized feed material with low over-crushing rates for grinding preparation. 1. Working Principle The working principle of the Huashengming double-roll crusher is highly efficient and intuitive: It relies on two parallel rollers (one fixed and one movable) driven by an electric motor to rotate in opposite directions. Lithium mica ore enters the crushing chamber formed between the rollers through the top feed opening, where it is continuously crushed by compressive and shear forces. The discharge particle size is precisely controlled by adjusting the gap between the rollers via a hydraulic system or a wedge/shim adjustment mechanism. Should uncrushable hard foreign objects (such as iron) enter the machine, the integrated hydraulic or spring overload protection system automatically retracts the rollers. Once the foreign object is discharged, the system automatically resets, effectively safeguarding the machine’s core components from damage. 2.Advantages Precise particle size control for optimized flotation efficiency: The flotation efficiency of lithium mica is highly dependent on the particle size distribution of mineral grains. Patented processes…

Can A Double-Roll Crusher Be Used As A Lepidolite Ore Crusher?

2025-11-28The lepidolite ore crusher (also known as a double-roll crusher) is fully capable of serving as crushing equipment for lithium mica ore, particularly during the medium and fine crushing stages. It effectively meets the requirements for particle size control and over-crushing rates in lithium mica mineral processing. 1. Working Principle The working principle of the double-roll crusher is highly intuitive and efficient: two rolls rotate toward each other driven by an electric motor. Lithium mica ore enters the crushing chamber formed between the rolls through the top feed opening, where it is continuously crushed by compressive and shear forces. The maximum discharge particle size can be precisely controlled by adjusting the gap between the two rolls. When uncrushable hard foreign objects enter the system, the equipment automatically retracts the rollers via spring or hydraulic overload protection systems. After the foreign object is expelled, the system automatically resets, effectively safeguarding the machine’s core components from damage. 2.Advantages Precise particle size control for optimized flotation efficiency The flotation efficiency of lithium mica is highly dependent on the particle size distribution of the mineral. Patented processes demonstrate that the sequence “jaw crusher for coarse grinding, double-roll crusher for fine grinding” ensures lithium mica…

Can A Double-Roll Crusher Be Used As A Lithium Ore Crusher?

2025-11-27The lithium ore crusher (also known as a double-roll crusher) is fully capable of serving as crushing equipment for lithium ore, particularly excelling in the medium and fine crushing stages where stringent requirements exist for product purity and particle size control. 1. Working Principle The working principle of the double-roll crusher is highly intuitive: two parallel rolls rotate toward each other driven by an electric motor. Material enters the crushing chamber formed between the rolls through the top feed opening, where it undergoes continuous compression and shearing forces to achieve fragmentation. The discharge particle size is precisely controlled by adjusting the gap between the rolls via simple mechanical or hydraulic mechanisms. Additionally, the equipment incorporates an overload protection mechanism (spring or hydraulic system). When uncrushable hard foreign objects enter, the rollers automatically retract to discharge the obstruction. Normal operation resumes afterward, safeguarding the core components from damage. 2. Advantages Eliminates metal contamination to ensure high purity of battery materials This represents the most critical advantage of double-roll crushers when processing lithium ore. Lithium battery cathode materials impose extremely stringent requirements on metal impurities such as iron (Fe) and chromium (Cr). By utilizing non-metallic materials like zirconia rollers, the process ensures…

Can A Double-Roll Crusher Be Used As A Magnetite Iron Ore Crusher?

2025-11-26Magnetite iron ore crusher (also known as a double-roll crusher) is perfectly suitable for use as a magnetite crusher, particularly during the medium and fine crushing stages, where it delivers outstanding performance. 1. Working Principle The working principle of the double-roll crusher is highly intuitive: two rolls rotate toward each other driven by an electric motor. Material enters the crushing chamber formed between the rolls from the top, where it is continuously crushed by compressive and shear forces. By adjusting the gap between the rolls (via a wedge device or shim adjustment), the maximum particle size of the product can be precisely controlled to meet diverse production requirements. 2. Advantages uperior particle size control with low over-grinding rate: Slow compression and shearing forces enable more uniform material fragmentation while significantly reducing the production of excessively fine powder. This is critical for subsequent mineral processing stages, as consistent feed particle size effectively enhances ore recovery rates. Energy-efficient and high-performance: Integrating double-roll crushers into grinding systems maximizes the production capacity of grinding equipment. Data indicates this typically boosts overall system output by 30%-40% while reducing total energy consumption by 20%-30%. Simple Structure and Easy Maintenance: Its relatively uncomplicated mechanical design translates to…

How Does The Double-Roll Crusher Perform As A Mine Dump Rocks Crusher?

2025-11-25The mine dump rocks crusher(also known as a double-roll crusher) is an excellent choice for rock crushing in mine stockpiles, particularly when processing medium to low hardness rocks, where it demonstrates significant advantages. 1.Working Principle The working principle of the double-roll crusher is straightforward and easy to understand: two rollers rotate relative to each other under motor drive. Material enters the V-shaped crushing chamber formed between the rollers from the top, where it is crushed through continuous compression and shearing forces. 2. Advantages Precise particle size control with low over-grinding rate: This is one of its core strengths. The maximum particle size of the product can be precisely controlled by adjusting the gap between the two rolls using simple mechanical or hydraulic devices. This slow extrusion process effectively minimizes the production of excessively fine powder, which is crucial for products requiring specific particle size ranges—such as high-quality concrete aggregates or ore before grinding. Energy Efficiency and High Performance: The equipment operates with high efficiency, achieving energy savings of up to 45% at equivalent output levels. Integrating a double-roll crusher for pre-crushing within the crushing system allows grinding equipment to achieve its full production capacity. Simple Structure and Easy Maintenance:…

Can A Double-Roll Crusher Be Used As A Mineral Crusher?

2025-11-24The double-roll crusher can certainly be used as a mineral crusher, and it performs exceptionally well when processing specific types of minerals. Simply put, it acts as a “specialist in precision crushing” within the mineral crushing field, excelling particularly in the medium and fine crushing of medium to low hardness brittle minerals. 1.Working Principle Two counter-rotating rollers draw material into the crushing chamber, where it is primarily broken down through gradually applied compressive and shear forces. This mechanism differs from the violent impact of impact crushing, enabling more precise control over the crushing process. It causes material to fracture along its natural cleavage planes, effectively reducing over-crushing rates and producing more uniformly shaped (cubic) particles. 2.Advantages Excellent particle size control with low over-grinding rate Simple structure and easy maintenance Good adaptability to sticky and wet materials Energy-efficient and environmentally friendly Sensitive overload protection

How About Choosing A Double-Roll Crusher For Ore Crusher?

2025-11-21The ore crusher (double-roll crusher) is the ideal choice for medium-to-fine crushing of medium-to-low hardness brittle minerals, offering both energy efficiency and particle size control advantages, particularly in the coal, building materials, and chemical industries. 1. Ore Crusher Working Principle Two counter-rotating rollers (smooth or toothed surfaces) apply compressive and shear forces to the material, achieving “selective crushing.” The material is slowly compressed within the roller gap rather than subjected to high-speed impact. 2. Advantages Uniform and controllable particle size: Roll gap can be adjusted via wedge devices or shims (typically ranging from 0.3–40 mm), resulting in low over-grinding rates (minimal dust) and suitability for applications demanding strict finished product particle size specifications (e.g., manufactured sand, chemical raw materials). Low Pollution and Heat Loss: Minimal heat generation during compression. Ceramic roll surfaces prevent metal contamination, preserving original mineral properties (e.g., coal coking characteristics, ore composition). Adaptability to sticky and wet materials: Compared to jaw or cone crushers, double-roll crushers demonstrate superior throughput for moisture-containing or viscous minerals (e.g., lignite, clayey ores) with reduced clogging tendencies.

How Does The Double-Roll Crusher Perform As A Stone Crasher Crusher?

2025-11-18Stone crasher crusher (also known as double-roll crushers) demonstrate exceptional performance in the field of stone crushing, particularly excelling in medium and fine crushing operations for medium to low hardness stone materials. 1. Core Performance Advantages High-Efficiency Crushing and Precise Particle Size Control Extrusion Crushing: Dual counter-rotating rollers generate high-pressure extrusion force (50-200MPa), progressively crushing materials through the “layer crushing” principle. This eliminates the instantaneous energy waste inherent in impact crushing, boosting crushing efficiency by over 30%. Precise, Adjustable Particle Size: Hydraulic or mechanical adjustment of the roll gap (0.5-40mm) ensures uniform, concentrated output particle size with low needle and flake content (high cubic particle ratio). Over-crushing rate <10%, making it ideal for manufactured sand (0-5mm) and construction aggregate (5-40mm) production. Energy Efficiency, Environmental Protection, and Cost-Effectiveness Low Energy Consumption: Power consumption per ton of crushed material ranges from 0.7 to 1.2 kWh, achieving 30%-45% energy savings compared to traditional hammer crushers and impact crushers. Environmental Compliance: Enclosed structure + pulse dust removal technology ensures dust emissions <20mg/m³ and noise ≤75dB(A), meeting green mining standards. Low Maintenance Costs: High-chromium alloy roll liners last over 2 years; modular design enables 1-hour rapid replacement, reducing annual maintenance costs by tens of thousands…

Can A Double-Roll Crusher Be Used As A Stone Crashing Crusher?

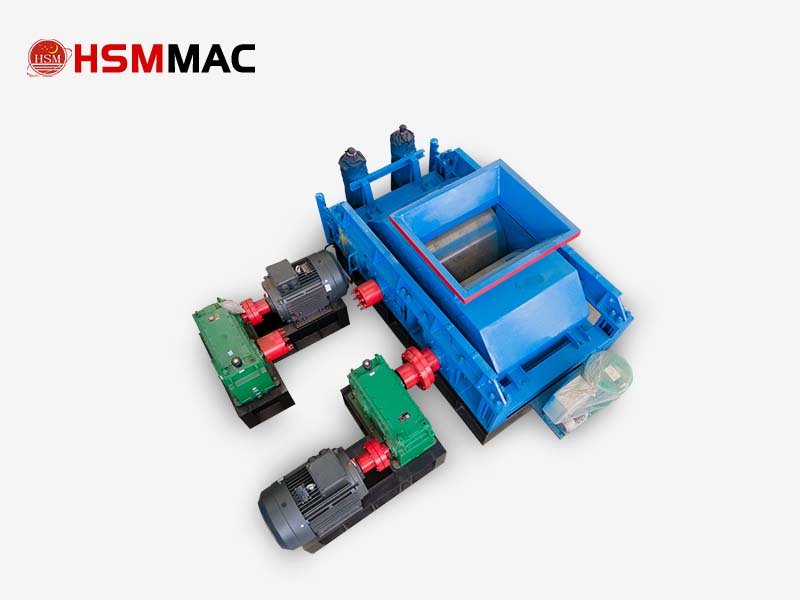

2025-11-17The double-roll crusher not only serves perfectly as a stone crashing crusher but also stands as a powerful tool for enhancing product value and reducing overall operating costs. With its robust crushing performance, economical operating costs, and reliable production output, it has proven itself to be the undisputed “powerhouse” and “efficiency expert” in sand and gravel production lines. 1. What is a double-roll crusher? The double-roll crusher, also known as a twin-roll crusher or dual-roll crusher, is a crushing device featuring a classic structure and an intuitive operating principle. It primarily consists of a frame, a pair of counter-rotating rolls, a power transmission system, and adjustment and safety devices. Its core design concept involves achieving material crushing through high-pressure compression between the two rolls, excelling particularly in controlling output particle shape and minimizing over-crushing. 2. What types of rock are being crushed? River pebbles, cobblestones, limestone, dolomite, potassium feldspar, sodium feldspar, phosphate rock, gypsum, coal, coke, and over 200 other materials. 3. Working Principle Two rollers rotate toward each other at the same speed or with a slight differential speed, driven by a motor and transmission mechanism. Stone material falls into the top feed opening and is drawn into the…

Why Choose A Double Roll Crusher Rock For Gold Ore Crushing?

2025-11-14Gold Ore Crusher In the fields of gold mining and mineral processing, ore crushing is a critical process step. With the continuous advancement of mineral processing technology, an increasing number of mining enterprises are selecting double-roll crushers as the primary equipment for gold ore crushing. I. rock for gold crusher Core Product Series High-Pressure Roller Mill (Flagship Model) Working Principle: Utilizes high-pressure layer crushing technology (100-150MPa pressure) to crush gold ore through opposing rotation of dual rollers, achieving “ore-on-ore crushing.” Output particle size: 0-5mm, with high mineral liberation. Model Parameters: Roll diameter ≥1500mm, hourly capacity 100-450 tons; Roll surface: High-chromium alloy + special hardening treatment, service life over 20,000 hours. Advantages: 30%-50% energy savings compared to traditional ball mill systems, 40% improvement in pre-grinding efficiency, suitable for large-scale mineral processing plants. Hydraulic Double-Roll Crusher Applications: Medium-fine crushing in small-to-medium gold mines, adjustable output size 1-30mm (hydraulic adjustment accuracy ±1mm). Representative Models: Medium: 2PGY1000×800 (50-80 tons/hour, 30kW×2 motors); Large: 2PGY1800×1000 (250-300 t/h capacity, intelligent CNC system). Features: Roll shells incorporate rare metal alloys (hardness HRC≥60), exceeding 2-year service life with low over-crushing rate. High-Power Classifying Crusher Technical Highlights: Low-speed, high-torque design combines crushing and screening functions; Spiral-arranged tooth discs enhance wear…

Why Can A Double-Roll Crusher Be Used As Basalt Sand Making Machine?

2025-11-10Basalt sand-making machine, also known as basalt double-roll crusher, is a crushing device that demonstrates numerous advantages in processing basalt. Designed specifically for the properties of basalt, this double-roll crusher offers exceptional quality and performance benefits, making it highly popular among basalt processing plants. Below is a brief introduction to the working principle, structure, and performance characteristics of this basalt double-roll crusher. 1. Structural Composition The basalt double-roll crusher primarily consists of a frame, crushing rolls, transmission mechanism, adjustment device, and spring safety device. Its overall structural design is exceptionally simple, innovative, and distinctive, featuring a high degree of automation. Operation and maintenance tasks are straightforward and convenient. 2. Working Principle The basalt double-roll crusher feeds crushed basalt through the inlet into the space between two rolls, where it undergoes compression crushing. Finished material then falls naturally. When encountering excessively hard or uncrushable material, the rollers automatically retreat via hydraulic cylinders or springs, widening the gap to allow the foreign object to pass, thereby protecting the machine from damage. The counter-rotating rollers maintain a controlled clearance; adjusting this gap regulates the maximum discharge particle size. 3.Performance Advantages Iron-Pass Protection for Stable Operation The basalt double-roll crusher is equipped with iron-pass…