The iron ore crusher is a crushing equipment independently developed by our company, incorporating the advantages of all roller presses available in the integrated market. It is suitable for fine crushing operations with compressive strength below 160 MPa, moisture content under 30%,feed size less than 80 mm, and finished product size requirements of 0.5-20 mm. Widely applicable in industries such as cement, mining, metallurgy,and ceramics, it features reliable performance, high output, low power consumption, and excellent cost-effectiveness.

Iron Ore Crusher

1.Iron Ore Crusher

Feed Size: 25-100mm

Production Capacity: 2-400 t/h

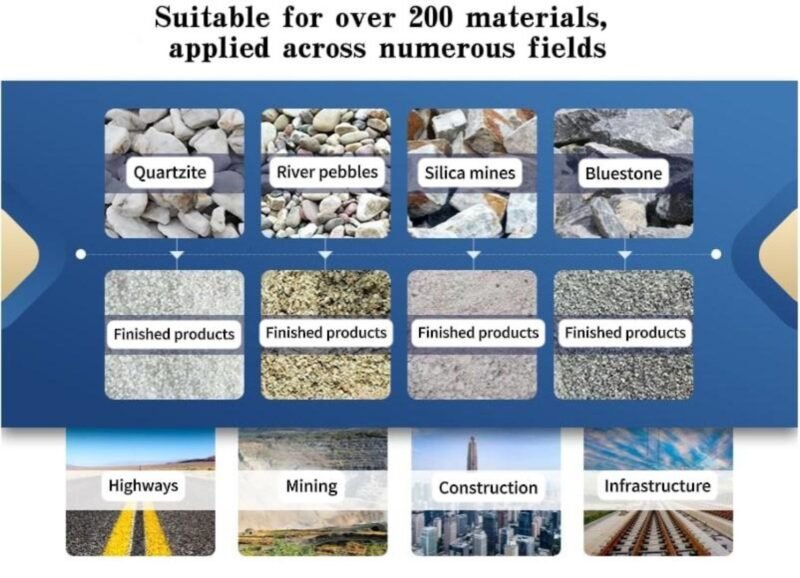

Suitable Materials

Highways, high-speed railways, high-rise buildings, municipal projects, hydroelectric dam construction, concrete mixing plants, sand and gravel quarries, etc.

Application Scope

River pebbles, calcite, quartzite, marble, cobblestones, bentonite, iron ore, bluestone, quarry rock, slag, limestone, weathered sand, diabase, granite, basalt, etc.

2.Configuration Comparison

3.Working Principle

The iron ore crusher performs crushing operations via roller wheels. Material enters between the rollers through the feed opening and is crushed by compression. A fixed gap exists between the two rollers. Increasing this gap produces larger discharge particle sizes, while compressing the gap with tension springs reduces the discharge particle size. By adjusting the gap, the discharge particle size can be precisely controlled.

4.Performance Advantages

1 Simple and lightweight with powerful crushing force

2 High efficiency, low energy consumption, and superior output quality

3 Wide applicability and extended service life

4 Intelligent control for energy savings and labor reduction