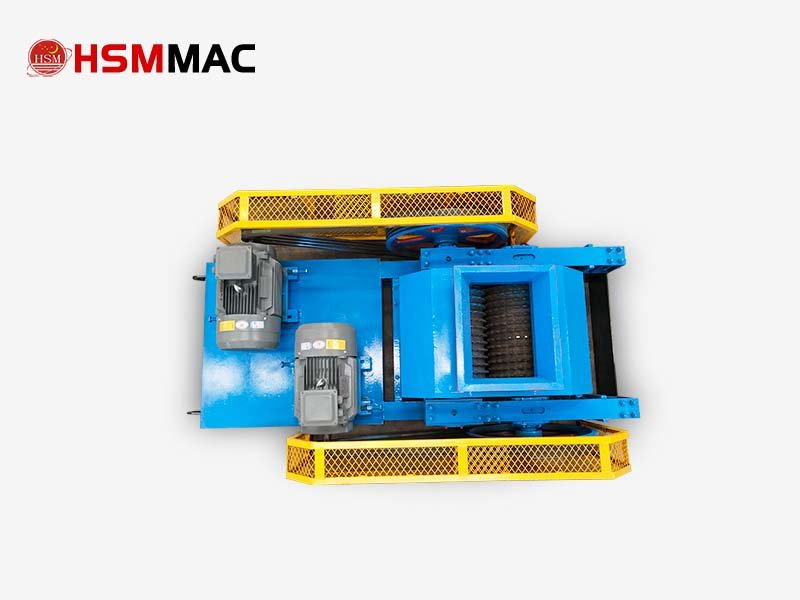

Huashengming Small Electric Rock Crusher Featuring dual-roll (precision particle size), jaw (large-block coarse crushing), and dual-stage (wet material specialist) core technologies, it covers applications including sand and gravel fine crushing, construction waste recycling, and tailings processing:

Small Electric Rock Crusher

1. Core Product Series and Model Specifications

Double-roll Crusher (Flagship Model)

Achieves precise sand production through dual-roll compression (adjustable particle size 1-50mm), with under-crushing rate <10%. Suitable for fine crushing of medium-hard rock.

| Model | Processing Capacity (t/h) | Output Particle Size (mm) | Motor Power (kW) | Application Scenarios |

| 2PGT400×250 | 2–10 | 1–3 | 7.5×2 | Construction Waste Recycling, Gold Mine Test Mining |

| 2PGT400×400 | 5–12 | 1–5 | 11×2 | Small-Scale Sand Plant, Limestone Sand Production |

| 2PGT610×400 | 5–20 | 2–8 | 15×2 | Coal Crushing, Quartzite Fine Crushing |

Technical Highlights:

Roll shells feature a high-chromium manganese steel + rare metal composite layer (triple-layer structure), with a lifespan exceeding 2 years (processing capacity > 30,000 tons);

Spring-adjustable roll gap (±1mm precision) enables granularity fine-tuning.

Jaw Crusher (Preferred for Primary Crushing)

Processes large rock blocks (feed ≤340mm), featuring simple structure and low maintenance costs.

| Model | Processing Capacity (t/h) | Maximum Feed Size (mm) | Motor Power (kW) |

| PE-150×250 | 1.2–3.5 | 125 | 5.5 |

| PE-250×750 | 5 | 210 | 15 |

Suitable Applications: Laboratory coarse crushing, small-scale quarries (e.g., primary crushing in gold mining)

Double-Shaft Impact Crusher (Specialized for Wet/Sticky Materials)

Dual-rotor design without screen bottom, supports direct crushing of materials with moisture content ≤15%, near-zero clogging rate.

| Model | 处理能力 (t/h) | Output Particle Size (mm) | Motor Power (kW) |

| 600×600 | 20–30 | ≤3 | 22+22 |

| 800×600 | 35–55 | ≤3 | 45+55 |

Advantages: Crushes high-moisture coal gangue and shale into fine sand in a single pass, eliminating the need for pretreatment.

2. Core Performance Comparison

| Specifications | Double-roll type | Jaw | Two-stage |

|---|---|---|---|

| Crushing Principle | Double-roll compression + shearing | Jaw plates reciprocating compression | Dual rotor impact + material self-collision |

| Output Particle Size | 1–50mm (adjustable) | 10–300mm (primary crushing) | ≤3mm (fine crushing) |

| Wet Material Adaptability | Medium (moisture content ≤10%) | Poor | Excellent (moisture content ≤15%) |

| Energy Consumption | 0.8–1.0kWh/ton (30% energy savings) | Moderate | Low (15–20% savings compared to traditional equipment) |

| Maintenance Costs | Roll skin lifespan >2 years | Jaw plate lifespan >2 years | Hammer replacement every 1–2 years |