Sand Raw Materials: More Than You Think!

2025-12-02Sand Raw Materials: More Than You Think! Most people associate sand with beach/river grains, but construction, road, and glass sand comes from diverse sources—far beyond natural quartz sand. Here’s the key breakdown: 1. Natural Sand: Nature’s Gift Formed by long-term natural processes, it has three main types: Quartz Sand: Most common (70% of natural sand use), from quartzite/granite. Hard, wear-resistant (SiO₂-based), ideal for construction/concrete. Feldspar Sand: From feldspar rocks (e.g., orthoclase). Less hard than quartz, red/pink, used in ceramics/glass auxiliaries—more affordable. Limestone Sand: From limestone/dolomite (CaCO₃). Soft, grayish-white, low-cost, for mortar/road bases. Over-mining harms ecosystems; China strictly restricts natural sand extraction. 2. Manufactured Sand: Natural Sand’s Main Replacement Mechanically crushed rock/ore, now mainstream (60% of China’s construction sand): Granite: “Golden raw material”—hard, angular, high compressive strength for high-rises/bridges. Limestone: Economical, abundant—40% of China’s manufactured sand, for ordinary construction/mortar. Basalt: Volcanic rock, wear-resistant—for expressways/airport runways. Slag Sand: Recycled steel mill blast furnace slag—green, enhances concrete density/corrosion resistance (marine/underground projects). Controllable particle size, no ecological damage. 3. Special-Purpose Sand Niche but critical: Glass Sand: High-purity quartz sand (SiO₂ ≥99.5%), impurity-free—core for glass production. Foundry Sand: Zircon/chromite/high-purity quartz sand—heat-stable for metal casting (precision parts). Beauty/Filter Sand: Round, impurity-free quartz/feldspar sand—for scrubs/water filtration….

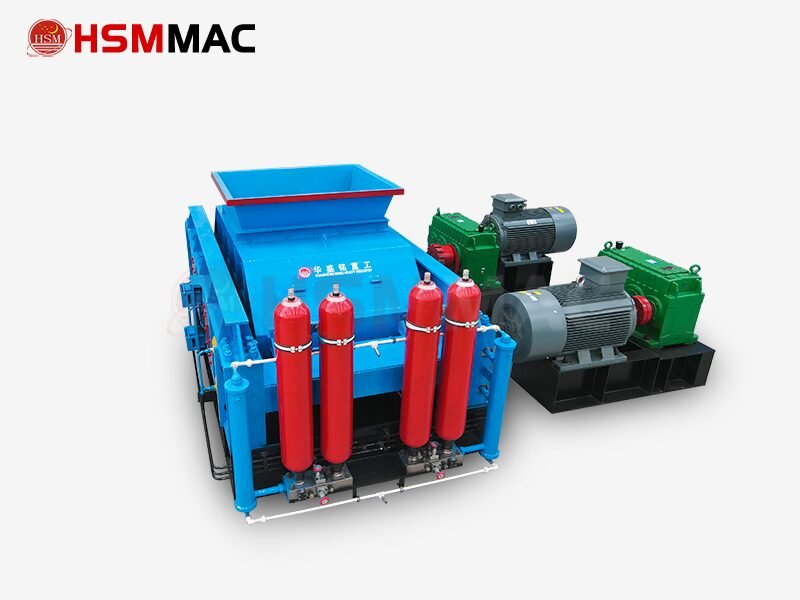

Sand Production Cost Of Sand Plant Is Too High Try To Use Roll Crusher

2025-08-03Sand Production Cost Of Sand Plant?For gravel plant operators, equipment maintenance is always a key factor affecting production efficiency. Traditional crushing equipment is often faced with fast wear and tear and frequent replacement of spare parts when processing materials in continuous operation, which not only increases the production cost, but also seriously affects the continuous operation of the production line. Durable crushing solution In response to this industry pain point, we have launched a new generation of roll sand making equipment, whose working method and structural design bring a brand-new production experience for sand and gravel plants. The roller crusher adopts the extrusion crushing method, and the material is gradually crushed by two rollers rotating in opposite directions. This working mode avoids the high-speed impact of traditional equipment, which fundamentally reduces the wear and tear of wearing parts. The equipment is equipped with high wear-resistant rollers, which are treated with multiple strengthening processes and have wear-resistant characteristics. Even if processing hard rock for a long time, it can still maintain good working condition. The roller crusher is equipped with a convenient gap adjustment device, the operator can quickly adjust the discharge size according to the production demand, to meet the…

China Roll Crusher Manufacturer Huashengming Heavy Industry

2025-08-02As a professional manufacturer of roll crusher in China, Huashengmeng Heavy Industry (Henan Gongyi) has outstanding performance in technology, durability and applicability of its products, especially in the field of medium and hard material crushing and construction waste recycling with significant advantages. The following is the core analysis that integrates multiple sources: 1. Core Technical Advantages High-efficiency crushing and energy-saving design Hydraulic system: Adopting patented hydraulic technology to adjust the roll gap (1-50mm), accurately control the discharge size (e.g., the discharge size of 2PG-750×500 model is adjustable from 1-3mm), reduce the over-crushing rate and improve the quality of finished products. Wear-resistant material: the roller skin is made of high chromium manganese steel alloy (thickened by 20cm), with special heat treatment, the service life can reach more than 3 years, reducing the replacement frequency and maintenance cost. Optimisation of energy consumption: Compared with traditional equipment, energy consumption is reduced by 20%-30%, and production capacity is increased by 30%-40% (e.g. 50 tonnes per hour for processing construction waste). Intelligence and Stability Automation control: supports one-key start/stop, overload automatic protection, equipped with centralised lubrication system, reducing manual intervention. Structural design: modular components for easy maintenance (such as maintenance window design), low vibration and…

Roller Crusher Application In Mineral Processing Industry

2025-07-14Roll crusher with its unique crushing principle . It has become the core equipment for medium and fine crushing in mineral processing industry. Flexible particle size control and low over-crushing rate. Roller crusher has high precision of crushing size control. The roller gap is adjusted by hydraulic or wedge device (1-50mm adjustable), the discharge size is uniform (e.g. 1-5mm sand). And the over-crushing rate is lower than that of the impact crusher. Roll crusher squeeze crushing reduces the subsequent grinding energy consumption by 15-30%, and the processing capacity is up to 1-400t/h (large fully hydraulic model supports 10,000 tonnes per day production). The following are its specific applications and technical characteristics in the field of mineral processing: Metal Ore Processing Rough crushing followed by medium crushing: located after the jaw crusher, it crushes the ore to the size range of 1-10mm, preparing for subsequent grinding or sorting. Tungsten and Tin Ore Beneficiation: In the combined process of ‘Roller Crusher + Jigger + Shaker’, the Roller Crusher controls the size of the discharged material (10-30mm), reduces over-crushing, and improves the efficiency of gravity sorting. Iron ore/non-ferrous metals: It is suitable for medium and fine crushing of copper, lead, zinc and other…

How To Solve The Wear During The Sand Crushing Process Of The Roller Crusher

2025-03-09I encountered severe wear during the sand crushing process of the roller crusher and would like to know a solution. You can learn through this article how to solve the wear problem of roller crushers in the sand making process? The main wear parts of the roller crusher are usually the roller surface, which is a high wear component. especially when dealing with hard materials. Considering sand making, common materials include limestone, granite, basalt, etc.The degree of wear and tear of different materials varies, so the solution may need to consider the characteristics of the materials.The solution includes material and process optimization, such as using high chromium alloy roller skin or welding technology to repair the roller surface.Equipment maintenance and operational factors also need to be considered, such as regular checks of clearances, the working status of lubrication systems, and control of feed particle size. In addition, it may involve adjustments to the process flow, such as pre screening to remove materials that are too fine or too hard. Improvement of roller surface material using gradient composite roller sleeve technology: The matrix is made of 42CrMo alloy steel with excellent toughness (yield strength ≥ 930MPa) The working layer is made…