What Are the Key Advantages of a Roller Crusher for Aggregate Processing?

2026-01-18In aggregate production, achieving a consistent, high-quality product is essential for profitability. The roller crusher offers distinct advantages that directly address the core needs of this industry. As a secondary or tertiary crushing machine, it provides the precision and reliability necessary to produce superior construction materials. A primary advantage is its exceptional control over product size and shape. Through its adjustable crushing gap, the roller crusher consistently produces a uniform output with a predictable top size. More importantly, its compressive action generates a high percentage of strong, cubical particles—the ideal shape for high-strength concrete and stable road bases. This leads to better compaction, improved workability, and a premium end product. Operational efficiency is another major benefit. The robust, straightforward design of this machine ensures high availability with lower maintenance costs. It consumes less energy per ton than many impact crushers, reducing power expenses. Furthermore, its ability to handle slightly abrasive or variable-feed materials with consistent results makes it a reliable cornerstone for any aggregate plant focused on quality and long-term cost-effectiveness. Seeking to upgrade your aggregate quality and plant efficiency? Discover how the key advantages of our roller crusher can transform your production.

Which Equipment Elevates Granite Sand Making Machine Output? Roller Crusher Is the Answer!

2026-01-15If your granite sand production line needs a significant boost in output, look upstream. The equipment that most directly elevates your sand making machine’s capacity is a well-configured roller crusher. It acts as a force multiplier for your entire plant by ensuring the core machine receives material it can process with maximum throughput. The roller crusher elevates output by creating a consistent, optimally sized feed. Granite that is too coarse or variable in size forces the sand maker to work harder, reducing its effective capacity. The roller crusher’s adjustable gap allows you to calibrate a uniform feed size perfectly matched to your sand maker’s intake requirements. This eliminates bottlenecks, promotes a steady material flow, and allows the sand maker to run at its full, continuous rated capacity. The result is a measurable increase in tons per hour of high-quality manufactured sand, turning a capacity constraint into a competitive advantage for your operation. Need to increase your plant’s hourly sand production? The answer starts with a roller crusher. Inquire about our high-capacity configurations today.

Roller Crusher: Critical Role in Construction Sand Feed Preparation

2026-01-14Producing high-quality construction sand begins long before material reaches the final sand-making machine. The most critical stage is feed preparation, and this is where a roller crusher proves indispensable. Acting as an efficient secondary crusher, it transforms primary-crushed rock into the ideal feedstock, setting the foundation for the entire manufacturing process. A roller crusher excels in this role due to its unique crushing principle. It applies controlled compressive force between two counter-rotating rolls, cleanly fracturing raw materials like granite or limestone. This action yields a more uniform, cubical product while actively minimizing the creation of fine, dusty particles. By providing the downstream sand maker with this consistent, optimally sized, and shaped feed, the machine dramatically improves overall system efficiency. It reduces wear on the sand maker’s components, enhances energy utilization, and ensures the final sand product meets strict specifications for gradation and particle shape, which are vital for high-strength concrete and mortar. Integrating this preparatory step is not just an option—it’s a strategic decision for profitability and product quality. A roller crusher delivers the precise control needed to maximize yield and optimize the entire sand production line. Ready to optimize your feed preparation? Contact us to learn how a roller crusher can become the cornerstone of…

Boost Sand Making Efficiency: Why Hydraulic Roller Crusher Is a Game-Changer for Your Plant

2026-01-13In the fast-paced world of sand making, every equipment choice directly impacts your plant’s productivity, cost-effectiveness, and product quality. Among the diverse crushing solutions available, the hydraulic roller crusher has emerged as a standout performer, redefining efficiency and reliability for sand making plants worldwide. Whether you’re processing limestone, granite, river pebbles, or recycled aggregates, this advanced crusher is tailored to meet the rigorous demands of modern sand production. Let’s dive into why it’s becoming the top choice for industry leaders. 1. What Makes Hydraulic Roller Crusher Unique for Sand Making? Unlike traditional crushers (such as jaw crushers or impact crushers) that rely on high-impact force, the hydraulic roller crusher operates on a compression-crushing principle. It features two rotating rollers (driven by a high-efficiency motor) that squeeze and grind raw materials into uniform particles. The integration of hydraulic systems adds a layer of intelligence and stability, making it far superior to conventional roller crushers in sand making scenarios: Adjustable Discharge Size with Precision: The hydraulic system allows stepless adjustment of the roller gap, enabling you to produce sand with different fineness (from 0-5mm to 0-10mm) according to market needs. This flexibility is crucial for adapting to diverse applications, such as concrete…

How to Choose a High-Efficiency Sand Making Plant?

2025-12-29Global infrastructure growth drives surging demand for high-quality artificial sand. A well-designed sand making plant is critical for the aggregates industry. Below are key tips for selection and latest trends to help you seize opportunities. 1. What Makes a High-Quality Sand Making Plant Stand Out? A reliable sand making plant is not a simple combination of equipment, but a systematic project integrating design, equipment matching, environmental protection, and intelligent control. Its core advantages are reflected in the following aspects: High Crushing Efficiency & Stable Output: The core equipment (such as impact crushers, cone crushers, and vertical shaft impact crushers) determines the production capacity. A high-quality plant adopts advanced crushing technology, which can process various raw materials (granite, limestone, river pebbles, etc.) efficiently, with a daily output ranging from several hundred tons to tens of thousands of tons, meeting the needs of different scales of projects. Superior Sand Quality: Equipped with sand washers and grading screens, the plant produces sand meeting national standards for shape, gradation, and cleanliness—comparable to natural sand. Energy-Saving & Eco-Friendly: Amid global carbon reduction, advanced plants have dust removal, noise reduction, and wastewater recycling systems to achieve green production. Intelligent & Easy to Maintain: Central control systems…

How does a roll crusher work?

2025-12-22The Basic Principles Explained A roll crusher operates through two parallel cylindrical rolls rotating inward towards each other. Material is fed into the gap between these rolls, where it is drawn in by friction and subjected to compressive force. As the rolls rotate, the material is progressively crushed until small enough to pass through the adjustable gap, determining the final product size. Key Working Mechanism: Material enters the top of the crushing chamber Counter-rotating rolls draw material downward Progressive compression breaks material into smaller pieces Crushed product exits through the bottom gap This simple yet effective mechanical process makes roll crushers ideal for secondary and tertiary crushing where controlled size reduction is essential. Interested in implementing this technology? Contact Huashengming for professional roll crusher solutions from Zhengzhou, China.

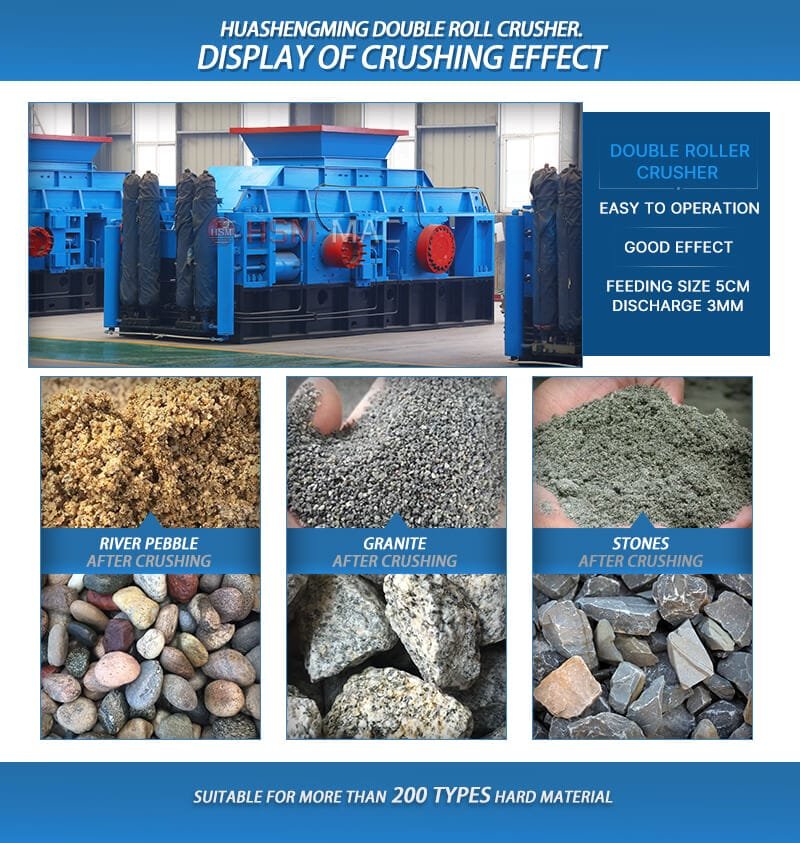

Which Company’s Crusher Is Best? Choose Huashengming Heavy Industry

2025-12-22When selecting crushing equipment for mining, construction or infrastructure projects, “which company’s crusher is best?” is a key question for buyers. Amid numerous manufacturers, Henan Huashengming Heavy Industry Machinery Co., Ltd. stands out as a trusted Chinese brand, winning global recognition for its high-performance, reliable crushers. Why Huashengming Crushers Stand Out in the Global Market In the competitive crushing equipment industry, Huashengming Heavy Industry has established a solid reputation by focusing on technological innovation, product quality, and customer-centric services. Here are the core advantages that make its crushers a top choice for customers worldwide: 1. Patented Wear-Resistant Technology for Long-Term Stability One of the biggest pain points in crusher operation is frequent replacement of wearing parts, which increases maintenance costs and downtime. Huashengming addresses this issue with its patented high-chromium manganese steel roller skin added with rare metals. This special material ensures that the wearing parts do not need to be replaced within 1 to 2 years, significantly reducing maintenance frequency and operational costs. The company has also obtained national patents for its roller design and precise discharge particle size adjustment technology, guaranteeing stable and consistent crushing results. 2. Versatile & High-Efficiency Huashengming’s crushers (especially double-roll series) handle various materials…

The Working Principle of Double Roller Crusher

2025-12-21As a widely used crushing equipment in mining, construction, and chemical industries, the double roller crusher is favored for its simple structure, low noise, and uniform crushing effect. If you’ve ever wondered how it efficiently crushes materials like coal, ore, and clinker, let’s break down its core working principle in plain terms. The most critical part of a double roller crusher is its two parallel cylindrical rollers. The core working logic lies in therelative inward rotation of these two rollers. When the equipment starts, the two rollers rotate in opposite directions at a stable speed (one clockwise and the other counterclockwise) driven by the motor and transmission mechanism. Core Working Logic: Relative Inward Rotation of Rollers The most critical part of a double roller crusher is its two parallel cylindrical rollers. The core working logic lies in the relative inward rotation of these two rollers. When the equipment starts, the two rollers rotate in opposite directions at a stable speed (one clockwise and the other counterclockwise) driven by the motor and transmission mechanism. When raw materials are fed into the feeding port above the two rollers, the rotating rollers will generate a downward traction force, drawing the materials into the…

What is a Roller Crusher? Essential Equipment for Modern Industry

2025-12-19The roller crusher serves as a fundamental component in material processing across multiple sectors, offering versatility, reliability, and precision in size reduction tasks. From primary mineral extraction to construction material preparation and industrial raw material processing, its robust compression-based design handles a wide variety of materials while maintaining consistent output quality and operational economy. Primary Industrial Applications: Mining & Quarrying – Secondary crushing of ores, coal, and industrial minerals Construction & Aggregates – Production of graded sand, gravel, and recycled concreteIndustrial Processing – Sizing of chemicals, fertilizers, and manufacturing raw materials Specialized Operations – Processing of salt, clay, brick materials, and selected food-grade products Seeking a crushing solution that balances performance with practicality? Contact Huashengming to discuss your project requirements—we deliver tailored roller crusher systems engineered for durability, efficiency, and seamless integration into your production workflow.

How Do Companies Produce Sand?

2025-12-10Sand is a vital raw material in construction, manufacturing and many other industries. But have you ever wondered how companies produce it on a large scale? Let’s break down the key steps simply. First, companies source raw materials. Common sources include quarried rock (like granite or limestone), riverbed aggregates, or even recycled concrete. These materials are chosen for their hardness and purity to ensure high-quality sand. Next comes crushing. The raw materials are fed into crushers to break them down into smaller pieces. Primary crushers handle large rocks, while secondary and tertiary crushers refine them into gravel-sized particles. Then it’s time for screening and washing. The crushed particles go through screens to separate sand-sized grains from larger debris. Washing is crucial too—it removes dirt, dust and impurities, making the sand clean and suitable for use. Finally, the processed sand is dried (if needed) and stored in silos before being transported to customers. Some companies also add additives to modify sand properties for specific uses, such as concrete production or glass making. From raw rock to usable sand, each step is designed to ensure consistency and quality. That’s the basic process behind industrial sand production!

Need High-Quality Aggregates & Sand for Your Sand Making Machine? Roller Crusher Delivers!

2025-12-03—— HSM Heavy Machinery: For Aggregate for Building Construction Sand Making Machine Systems High-quality aggregates/sand are critical for construction (concrete, roads, etc.). If your aggregate for building construction sand making machine struggles with uneven particles or excess powder, HSM Roller Crusher solves this—delivering precise, standard-compliant output to boost efficiency and value. Why Choose Our Roller Crusher? Precise, Ready-to-Use OutputAdjustable roller gaps create uniform cubic particles (low needle-like content, minimal powder) that meet ASTM/EN/GB standards. No secondary screening needed—cut costs and speed up production. Works With All MaterialsTailored for aggregate for building construction sand making machine systems: handles medium-soft rocks, construction waste, and fragile materials (e.g., gypsum) without over-crushing. Seamless IntegrationFits your existing line: pairs with jaw crushers, reduces secondary equipment reliance, and runs 24/7 with low maintenance. Cost-Effective Quality UpgradeEliminate waste and energy costs—get fast ROI, whether you run a small plant or large operation. Ready to Elevate Your Output? HSM Roller Crusher delivers consistent, efficient results. We offer custom setups + full support.

How Does a Double Roller Crusher Work?

2025-12-03If you work in mining, construction, or aggregate processing, you’ve probably heard of the double roller crusher—a go-to machine for crushing hard materials like coal, ore, and limestone. But how exactly does it turn large chunks into smaller, usable particles? Let’s break down its working principle in 3 easy steps. 1. Material Feeding: The First Step The process starts with feeding raw materials into the crusher’s hopper (a large funnel-like structure). The hopper guides the material evenly between two parallel, rotating rollers—these are the “heart” of the machine. To avoid jams, most crushers have a feeder that controls the material flow, ensuring the rollers never get overloaded. 2. Crushing: Pressure Does the Work Here’s the core part: The two rollers spin toward each other (one driven by a motor, the other following via friction). As the material falls between them, the rollers apply intense compressive pressure. This pressure squeezes and grinds the material until it breaks into smaller pieces. The size of the final product? It’s controlled by the gap between the rollers. Adjust the gap (wider for larger particles, narrower for finer ones), and you get exactly what your project needs—no extra processing required. 3. Discharge: Collect the…