The Key Role of the Impact Crusher in Brick Processing for Sand Making

2025-12-15The Impact Crusher serves as the crucial intermediary in brick recycling systems, specifically engineered to prepare demolition materials for your Bricks Sand Making Machine. Positioned after primary crushing, it transforms irregular brick fragments into optimally shaped feed through controlled impact mechanics. Three Essential Functions: 1.Shape Optimization: Produces dense, cubical particles that enhance crushing efficiency in your Bricks Sand Making Machine 2.Size Calibration: Features adjustable settings to match your sand maker’s specific input requirements 3.Material Refinement: Helps separate brick from residual mortar, improving both feed quality and final sand specifications System Integration Benefits: Increases overall processing efficiency through optimized material preparation Reduces wear on downstream equipment components Ensures consistent feed quality for uniform sand production Manufactured by Huashengming in Zhengzhou, China, our Impact Crushers work seamlessly with our complete equipment range – from primary jaw crushers to specialized Bricks Sand Making Machines – creating efficient systems that transform demolition waste into valuable construction materials.

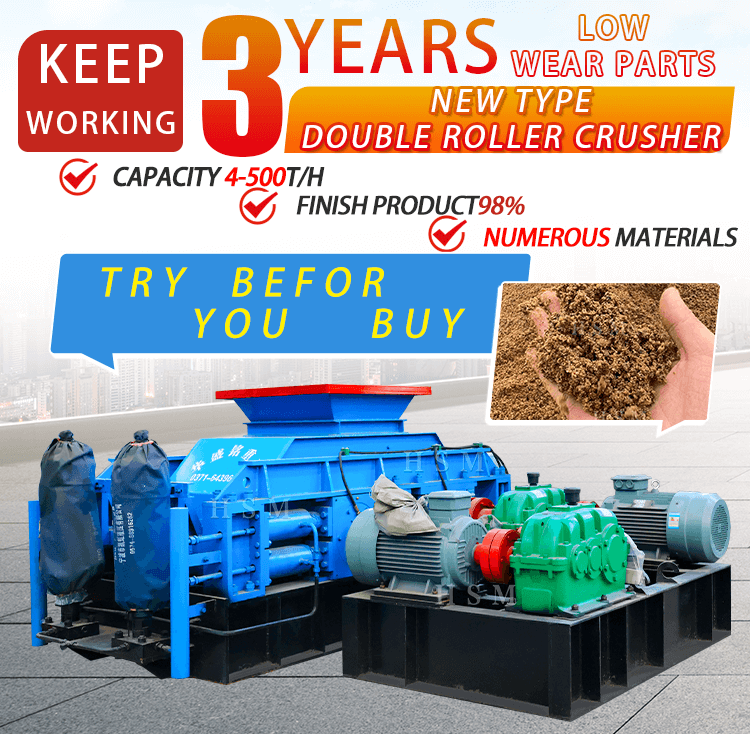

Why a Roller Crusher is Essential for Quality Soil Sand Production

2025-12-13When establishing a high-efficiency soil sand production line, selecting the right primary crushing equipment is pivotal to end-product quality and operational throughput. The Huashengming Roller Crusher serves as the optimal soil pre-processing unit. Its unique performance advantages directly enhance the operational efficiency of your soil sand making plant. 1.Preserving Soil Structure Maintaining the natural bonding properties of soil is critical for sand production. The Huashengming Roller Crusher employs gentle compressive force: it reduces large soil aggregates while retaining clay’s cohesive characteristics. This yields optimized feedstock for your soil sand making system to produce high-bonding manufactured sand. 2.Handling Variable Soil Conditions Diverse soil types demand adaptable processing solutions. The Roller Crusher is compatible with a full spectrum of soil materials—from sandy loam to high-clay substrates. Unlike conventional crushers, it accommodates material variability within soil sand production systems with minimal downtime. 3.Preparing Ideal Feed Material Positioned upstream of your soil sand making equipment, the Roller Crusher produces uniformly sized, moderately compacted feedstock. This not only elevates the gradation quality of the final sand but also enables your soil sand making unit to operate at rated capacity, delivering construction-grade sand with optimal bulk density and workability. 4.Environmental & Economic Benefits By processing…

Precision Preparation: Why a Roller Crusher is Ideal Before Your Granite Sand Making Machine

2025-12-121. Strategic Positioning in Processing Flow Positioned between the primary jaw crusher and the final granite sand making machine, the Roller Crusher plays a crucial optimization role in granite sand production systems. 2. Controlled Compression Technology Its unique controlled compressive crushing action produces more cubical, well-graded intermediate product with significantly lower and predictable fines content—unlike impact crushers that create excessive fines from hard granite. 3. Optimizing Sand Maker Performance This perfectly prepared feed reduces wear on the granite sand making machine components, enables more efficient rock-on-rock crushing, and directly contributes to producing premium manufactured sand with optimal particle shape for construction applications.

The Precision Choice: Why a Roller Crusher is Essential for Marble Processing

2025-12-11Marble processing requires equipment that balances crushing efficiency with material preservation. Our Roller Crusher serves as the ideal secondary crushing solution for marble for several key reasons. Unlike high-impact crushers that can shatter the crystalline structure of marble, the roller crusher’s controlled compression method creates a more predictable breakage pattern. This results in more uniform particle distribution and better shape characteristics – crucial for premium marble applications. As a manufacturer in Gongyi, Zhengzhou, we’ve engineered our roller crushers specifically for the unique characteristics of marble, ensuring optimal particle shape for both construction aggregate and feed preparation for sand making processes. Discover the difference precision crushing makes. Contact us to discuss your marble processing needs.

What Is Artificial Sand Called?

2025-12-11Artificial sand is increasingly used in construction, but do you know its English names? The most widely used terms are artificial sand and manufactured sand. In daily industry communication, the shorthand M-sand is also very common. Occasionally, it may be called synthetic sand, but this expression is not mainstream in construction scenarios. Different from natural sand formed by long-term natural erosion, artificial sand is made by crushing, screening and washing hard materials like rocks or mine residues. Due to the shortage of natural sand resources and stricter environmental protection requirements, it has become a popular substitute in the global construction field.

The Optimal Feed Preparation: Why Start Your Dolomite Sand Plant with a Roller Crusher

2025-12-101. Foundation of Quality Sand: Perfect Feed Preparation Producing high-quality manufactured sand from dolomite starts with optimal feed preparation. Consistent, well-sized feedstock is key to maximizing your dolomite sand making machine efficiency. 2. Strategic Choice: Roller Crusher for Secondary Crushing Integrating a Huashengming Roller Crusher between your primary crusher and sand maker is a strategic optimization. It transforms coarse aggregate into ideal feedstock for your dolomite sand making machine. 3. Superior Principle: Controlled Compression Technology Unlike impact crushers that create excess fines, our Roller Crusher uses controlled compressive crushing to produce more cubical particles with lower, more consistent fines content. 4. Tangible Benefits for Your Plant Optimized feed delivers measurable results: Reduces Wear & Costs: Minimizes abrasion on sand maker components Improves Efficiency: Enables higher throughput with better energy utilization Ensures Quality: Guarantees final sand meets concrete/construction specifications 5. From Raw Material to Premium Sand Our Roller Crusher refines and prepares dolomite aggregate into high-quality feedstock, enabling your dolomite sand making machine to produce superior sand profitably. Ready to optimize your dolomite sand production? Contact us to learn how our Roller Crusher enhances plant performance and profitability.

How Do Companies Produce Sand?

2025-12-10Sand is a vital raw material in construction, manufacturing and many other industries. But have you ever wondered how companies produce it on a large scale? Let’s break down the key steps simply. First, companies source raw materials. Common sources include quarried rock (like granite or limestone), riverbed aggregates, or even recycled concrete. These materials are chosen for their hardness and purity to ensure high-quality sand. Next comes crushing. The raw materials are fed into crushers to break them down into smaller pieces. Primary crushers handle large rocks, while secondary and tertiary crushers refine them into gravel-sized particles. Then it’s time for screening and washing. The crushed particles go through screens to separate sand-sized grains from larger debris. Washing is crucial too—it removes dirt, dust and impurities, making the sand clean and suitable for use. Finally, the processed sand is dried (if needed) and stored in silos before being transported to customers. Some companies also add additives to modify sand properties for specific uses, such as concrete production or glass making. From raw rock to usable sand, each step is designed to ensure consistency and quality. That’s the basic process behind industrial sand production!

Hydraulic Roller Crusher: Core Choice for Large-Scale Crushing

2025-12-09Looking for a reliable large-scale roller crusher? The hydraulic roller crusher stands out in mining, construction and other industries with its unique advantages. Equipped with advanced hydraulic adjustment system, it enables smooth gap control between rollers, ensuring consistent product size. Its heavy-duty roller design enhances wear resistance, reducing maintenance frequency and extending service life. Compared with traditional crushers, it features lower noise, less energy consumption and higher crushing efficiency—ideal for processing limestone, coal, ore and other materials. Whether for primary or secondary crushing, this machine delivers stable performance. Want to know more about its specifications? Leave your message below!

High-Capacity & Efficient Coal Crusher | Double Tooth Roll Crusher by Huashengming

2025-12-09For high-volume primary or secondary crushing of coal, lignite, and sticky materials, our Double Tooth Roll Crusher is the optimal coal crusher choice. Engineered by Huashengming Heavy Industry in Gongyi, China, this robust machine utilizes two counter-rotating toothed rolls to deliver powerful splitting and shearing action, ideal for effectively breaking down large feed sizes and handling challenging materials. It excels where high throughput and reliable processing of moist or adhesive coal are key. The interlocking tooth design ensures efficient capture and crushing of lumps, reducing the risk of clogging and maintaining consistent flow. Built for reliability in the most demanding conditions, its extra-heavy-duty design ensures long service life with straightforward maintenance. Key advantages of this coal crusher include: High Throughput Capacity: Engineered for large-scale, continuous processing demands. Handles Sticky & Moist Materials: Toothed roller design minimizes clogging for higher uptime. Effective Lump Breaking: Powerful action for primary reduction of run-of-mine (ROM) coal and shale. Robust & Durable Construction: Built with wear-resistant alloys to withstand abrasive environments. If your operation requires a reliable coal crusher for high-capacity processing and tough material conditions, our Double Tooth Roll Crusher provides the perfect balance of power, durability, and efficiency. Request detailed specifications and a quote for our Double Tooth Roll Crusher solution…

Box Hammer Crusher: A Reliable Primary Crusher Option

2025-12-06As a popular primary crushing equipment, the box hammer crusher stands out for its practicality—here are its core highlights and key traits: One-step crushing efficiency: Eliminates the need for secondary crushing for many materials (e.g., limestone, coal gangue), reducing process complexity and saving space. Strong crushing capacity: Hammer design delivers high impact force, handling large feed sizes (up to several hundred millimeters) with ease. Low operational costs: Simple structure means fewer wearing parts; maintenance is quick and affordable compared to complex primary crushers. Versatile application: Ideal for primary crushing of brittle, medium-hard materials in construction, mining, and road-building projects. Stable performance: Closed box structure ensures safe operation, while uniform discharge meets basic secondary processing requirements. For projects seeking cost-effective, efficient primary crushing, this crusher balances performance and practicality—worth considering for your material processing needs.

5 Core Advantages: Double-Roll Crusher for River Pebble Crushing

2025-12-06Double-roll crushers are well-suited for river pebble crushing, thanks to their unique working principle and structural design. Here are their key advantages: 1. High Adaptability to Hard Materials Adopting low-speed extrusion crushing, it makes river pebbles break along natural cracks. Equipped with wear-resistant alloy roller skins, it effectively resists the abrasiveness of river pebbles, reducing equipment wear and ensuring stable operation. 2. Excellent Finished Product Quality The particle size can be precisely controlled by adjusting the roller gap. The finished aggregates are mostly sub-angular or near-cubic, with low flakiness content and continuous gradation, meeting the requirements of construction scenarios such as concrete mixing. 3. Energy-Saving and Cost-Effective Compared with impact crushers, it operates at a lower speed with less energy consumption. The structure is simple, with fewer wearing parts that are easy to replace, minimizing daily maintenance workload and long-term operating costs. 4. Safe and Eco-Friendly Operation Without high-speed rotating components, it runs smoothly with low noise, suitable for production sites near residential areas. The sealed crushing cavity reduces dust leakage, complying with environmental protection requirements for green production. 5. Reliable and Easy to Maintain It has a built-in overload protection system. When encountering uncrushable foreign objects, the roller can…

Jaw Crusher vs. Roll Crusher: Key Differences

2025-12-05Jaw Crusher vs. Roll Crusher. Wondering which crusher fits your needs? Let’s break down the core differences between jaw crushers and roll crushers. 1. Core Structure Jaw Crusher: Has a fixed jaw and a movable jaw (like a “jaw” shape) that moves back and forth. Roll Crusher: Features 2–4 rotating rolls (smooth or toothed) that work in pairs. 2. Crushing Principle Jaw Crusher: Uses “compression crushing” — the movable jaw squeezes materials against the fixed jaw to break them. Roll Crusher: Relies on “shearing & squeezing” — rotating rolls grab and crush materials between them. 3. Suitable Materials Jaw Crusher: Ideal for hard/abrasive materials (granite, basalt, ore) — great for primary crushing. Roll Crusher: Better for medium-soft materials (coal, limestone, clay) — often used for secondary crushing. 4. Final Product Jaw Crusher: Output has irregular shapes; particle size varies more. Roll Crusher: Produces uniform, cubical particles with less dust — good for strict size requirements.