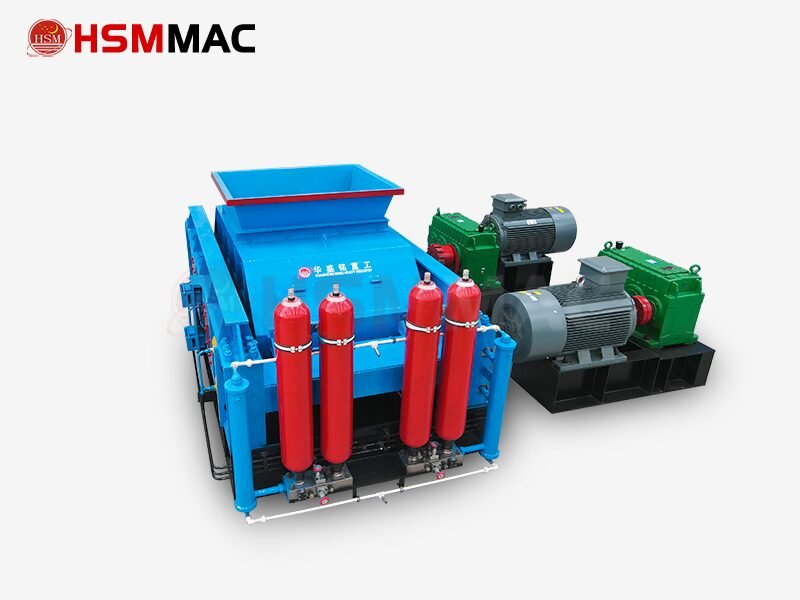

For High-Quality Crushers, Choose Huashengming Double-Roll Crushers.

2025-08-19Huashengming High-Quality Crusher: We have specialised in mining machinery for 20 years, served over 3,000 customers, and exported to 30 countries worldwide. Let us show you the high-quality crushers we produce. 1. Core Technical Advantages Hydraulic Precision Control The discharge particle size is adjustable from 1 to 5 mm. The roller gap is adjusted in real time via the hydraulic system to ensure uniform particle size of the finished sand and a over-crushing rate below industry standards. Equipped with an overload protection device, it automatically retreats upon encountering foreign objects like iron blocks, preventing equipment damage. Wear-Resistant and Durable Design High-chromium manganese steel roll liners with a hardness of over 8 on the Mohs scale, offering a lifespan of up to 2-3 years (counterfeit products last only 3-6 months). The roller body is thickened to 20 cm, and large models (such as the 2PGY2000×1000) can operate continuously for 18 months without faults. Highly adaptable to complex operating conditions Screenless design: effectively processes high-moisture materials (such as coal slurry, construction waste) without blockages, with a 40% increase in wet material throughput. Dual motor drive: energy consumption is 30% lower than traditional equipment, with large models producing 400 tonnes per hour…

High-Quality Rock Crusher For Sale By Huashengming

2025-08-18Huashengming Heavy Industry’s rock crushers are characterised by high wear resistance, intelligent control, and strong adaptability, catering to diverse crushing needs ranging from small and medium-sized mines to construction waste recycling. Below are the main models, performance features, and purchasing guidelines: 1. Core Product Line and Technical Advantages Wear-Resistant and Durable Design Roll Shell/Hammer Material: Made from high-chromium manganese steel alloy (containing ≥12% chromium), offering three times the wear resistance and a service life exceeding 8,000 hours. Screenless Structure: Dual-stage crushers (e.g., SCF series) feature a screenless design, preventing blockages in wet or sticky materials and maintaining efficient crushing even with moisture content ≤15%. Intelligent Control and Precise Particle Size Hydraulic Adjustment System: Roll crushers (such as the 2PGY series) support infinite adjustment of the roll gap from 1–50 mm, with an output particle size error of ≤±2 mm and a cubic particle ratio of >85%. Automated Operation: Equipped with an intelligent control system, it can be operated by one person, with an over-crushing rate of <5%, reducing labour costs. Environmental Protection and Low Energy Consumption Closed crushing chamber + dust collection system, reducing dust by 60% and noise levels below 85 dB. Energy consumption is only 0.5–0.8 kWh/tonne, achieving…

Stone Material Double-Roll Crusher For Sale And The Uses Of Double-Roll Crushers

2025-08-17The double-roll sand-making machine, as a classic crushing device, is renowned for its durability, efficiency, and energy savings. Its main models include the spring series, hydraulic series, and reinforced series, each designed to meet different production requirements. These machines feature a double-roll structure, allowing the output particle size to be controlled by adjusting the distance between the two rolls, making them suitable for materials of various hardness levels. Their unique wear-resistant materials extend service life and reduce maintenance costs. Prices vary depending on the model and configuration, ranging roughly from several thousand to several hundred thousand RMB. 1. Core Advantages: Why Choose a Double Roll Crusher? Precise Particle Size Control By hydraulically or mechanically adjusting the distance between the two rolls (typically adjustable from 30 to 200 mm), the output particle size is uniform and controllable, reducing over-crushing rates by over 30%, with cubic particle content exceeding 80%, meeting the gradation requirements for construction aggregates. Compared to traditional jaw crushers or hammer crushers, the finished product has a more concentrated particle size distribution, reducing subsequent screening costs. High Efficiency, Energy Saving, and Cost-Effectiveness The double-roll compression crushing principle has low energy consumption, with a power consumption of only 0.5–0.8…

Concrete Crusher Selects Double-Tooth Roller Crusher

2025-08-15In the field of concrete crushing, double-tooth roller crushers (counter-roller crushers) have become the preferred equipment for processing construction waste (such as concrete blocks and waste bricks and tiles) due to their unique crushing mechanism and performance advantages. The following is a professional interpretation from four dimensions: applicability analysis, core advantages, selection points, and precautions. 1. Double-tooth roller crusher Applicability Analysis: The ideal choice for crushing medium-to-low hardness concrete Material Property Compatibility The aggregates in concrete (such as limestone and crushed stone) are medium-to-low hardness brittle materials (compressive strength ≤ 70 MPa), which aligns perfectly with the design intent of the double-tooth roller crusher. Through a combination of compression and shear crushing, it efficiently breaks down concrete blocks while preserving the angularity of the aggregates, thereby enhancing the compressive strength of recycled aggregates. Moisture Content Adaptability Supports processing of wet, sticky concrete blocks with moisture content ≤15%. The shear force generated by the rotating rollers can peel off adhered asphalt or cement paste, preventing blockages (traditional jaw crushers often experience reduced efficiency due to wet material adhesion). Application Scenario Validation Construction Waste Recycling: Crushing concrete precast panels and brick-concrete structure waste to produce recycled aggregate (0-50mm) for roadbed filling…

Portable Rock Crusher Choose Portable Roll Crusher

2025-08-13Portable rock roll crusher core structure and working principle Portable roll crusher is integrated by double roll crushing host and mobile chassis, the core components include: Crushing system: two rollers rotate in opposite direction, crushing materials through extrusion and shear force, roll gap can be adjusted hydraulically or mechanically (wedge/shim device), controlling the size of discharged materials (usually 0-40mm). Mobile chassis: tracked (complex terrain) or tyre (flat site), equipped with hydraulic steering and lifting system to achieve flexible steering and stable operating support. Drive and Intelligent Control: High-voltage motor drive (up to 1600kW for some models), integrated PLC hydraulic system automatically adjusts the roller pitch, adapting to different material hardness and reducing the over-crushing rate. High mobility and deployment efficiency No need for fixed foundation, can be quickly transferred (crawler moving speed up to 1.2m/min), reduce the cost of material transport. Applicable scenarios: on-site crushing of construction waste, temporary mining area of mines, river sand and gravel processing, etc. Intelligent adjustment and efficient crushing Hydraulic system adjusts roll spacing (1-20mm) in real time, adapting to hard rock such as river pebbles, granite (compressive strength ≤160MPa), with large crushing ratio and 30%-40% capacity increase. Closed design + bag dust collector, reduce…

Huashengming Heavy Industry Rock Crusher For Sale

2025-08-12Huashengming Heavy Industry rock crusher for sale: professional quality helps mine mining new chapter! At a time when mining and infrastructure construction continue to expand, high-quality rock roller crusher has become the core equipment to improve production efficiency. As a famous brand in China’s mining machinery field, Huashengmeng Heavy Industry, with deep technical accumulation and excellent manufacturing strength, continues to provide global users with reliable performance and adaptable rock crushing solutions. Choosing Huashengmeng Heavy Industry means choosing a solid guarantee for efficient crushing and long-term stable operation! 1. Professional crushing, strength casting reliable quality Huashengmeng Heavy Industry has been focusing on the research and development of roller crusher for more than 30 years: Sturdy and durable: the key components adopt high-strength alloy steel, strong impact resistance, equipment life increased by 50% High efficiency and energy saving: optimized rock crusher crushing chamber design + hydraulic adjustment system, crushing efficiency increased by 30%, energy consumption reduced by 25% Intelligent control: optional PLC intelligent control system, real-time monitoring and control of operating parameters, the failure rate decreased by 40% Multi-model adaptability: to provide more than 30 types of rock crusher with an hourly output of 50-2000 tonnes to meet the needs of granite…

Sand Crusher Machine Also Known As Double Roll Crusher

2025-08-10Sand and gravel roller crusher (also known as double roller crusher, roller sand making machine) is a kind of core equipment through the two parallel rollers rotating in opposite direction to squeeze the material to achieve the medium and fine crushing operation, which is widely used in the fields of sand and gravel aggregate production, mining, building materials and so on. The following is an analysis of the core structure, performance characteristics and application selection: 1. Core structure and working principle Crushing Mechanism The material falls into between two rollers from the upper inlet, and is crushed by the extrusion (50-200MPa high pressure) and shear force generated by the roller rotating in the opposite direction (usually adopting differential speed design). The roller gap is adjustable (hydraulic or wedge system), controlling the size of the discharged material within the range of 0.5-40mm. Key Components Roller: The surface is divided into smooth roller (fine crushing) and toothed roller (coarse crushing), adopting high manganese steel or alloy wear-resistant material, the roller skin of some models is thickened to 20cm, the service life is up to 3 years. Driving system: dual motor belt drive, hydraulic model supports automatic gap adjustment and overload protection. Auxiliary…

Concrete Crusher Recommendation: Concrete Roller Crusher

2025-08-09Concrete Roller Crusher crushes materials by squeezing them with two high strength alloy rollers rotating in opposite direction. After entering the gap between the rolls (V-shaped crushing chamber), the material is crushed to the target size by squeezing force, shear force and mutual friction. Discharge size is controlled by adjusting the gap between rollers (such as hydraulic or spring device automatically adjusted), and the rollers are automatically separated to protect the equipment in case of over-hard materials. 1. Concrete crusher core performance characteristics Concrete roller crusher applicable material range Compressive strength ≤250MPa: designed for concrete, construction waste (moisture content ≤35%), asphalt blocks, bricks and so on. High hardness material limitation: over 250MPa need to switch to roll crusher. Flexible and adjustable discharge size Flat roller surface: feed <80mm, discharge 1-10mm (fine crushing). Surfaced rollers: feed <150mm, discharge 5-30mm (medium and fine crushing). Real-time gap adjustment by wedge bolt or hydraulic system (e.g. Huashengming 1012). Environmental protection and low loss design Low over-crushing rate: Extrusion + shear crushing reduces the generation of powder, and the finished product has uniform particle size (over-crushing rate <10%). Dustproof and noise reduction: sealed structure + dustproof plate to suppress dust, noise ≤ 75dB. Self-cleaning roller:…

Stone Roller Crusher Machine Price?

2025-08-07Stone Roller Crusher Price?The price of Stone Roller Crusher varies a lot due to model, capacity, automation degree and brand, which can be divided into the following 3 kinds: 1. Small Roller Crusher (for individual or small business) Model example: 2PG400×250, 2PG400×400, 2PG610×400 Output range: 5-35 tonnes/hour (e.g. 2PG610×400 model output 13-35 tonnes/hour) Price range: Basic spring drive type: 10,000-40,000 yuan (e.g. 2PG250×150 about 17,000 RMB) Semi-automatic/hydraulic type: 30,000-80,000 RMB 2. medium-sized roll crusher (for small and medium-sized production) Model example: 2PG800×600, 2PG800×800, 2PG1000×800 Output range: 20-50 tonnes/hour Price range: 80,000-200,000 RMB, depending on the automation configuration (direct-connected lower, fully hydraulic higher) 3. Large-scale fully-automatic hydraulic roll crusher (industrial-scale production) Model example: 2PG1200×800, 2PG1500×1000, 2PG1600×1000 Output range: 80-150 tonnes/hour Price range: 200,000-500,000 RMB or more, the high configuration models up to hundreds of thousands of dollars Matching demand: small production choose 30,000-80,000 yuan model, large-scale projects need more than 200,000 hydraulic models. Quality Priority: Roller skin wear resistance directly affects the long-term cost, low-priced equipment may be maintained frequently. Inquiry verification: Manufacturers quote with configuration details (e.g. motor power, discharge size), it is recommended to contact directly to get a customised solution (example: Xingmin 2PG900×500 quoted at 67,000 RMB). Stone…

Quartz Sand Making Machine Choose Roll Sand Making Machine

2025-08-06Quartz sand making machine is a kind of equipment designed for crushing medium and high hardness materials such as quartz sand, which achieves high efficiency sand making through the principle of double roll extrusion. With adjustable particle size, low energy consumption and high abrasion resistance, quartz sand roller sand making machine has become an ideal choice for quartz sand processing. When selecting the model, it is necessary to integrate the material characteristics, production capacity and intelligent demand, and give priority to models with patented wear-resistant technology and hydraulic system (such as Huashengming 2PGY series) to ensure long-term and efficient operation. 1. quartz sand making machine working principle The material (such as quartz sand) enters into the crushing chamber from the inlet, and is squeezed, rubbed and sheared by the two oppositely rotating rollers, and the granularity of the discharged material (usually 1-5mm) is precisely controlled by adjusting the gap between the rollers (controlled by hydraulic or spring system). The equipment is equipped with an overload protection device, which automatically backs off or stops the machine when it meets hard objects to avoid damage. 2. quartz sand roller sand making machine performance advantages High efficiency and energy saving 50% energy saving…

Ore Crusher Preferred Roll Crusher

2025-08-05Ore Crusher Preferred Roll Crusher. Roll crusher has become the core equipment for cost reduction and efficiency increase in mineral processing industry by virtue of its high efficiency crushing, precise particle control, energy saving, intelligent operation and maintenance and wide adaptability. In the future, with the deep integration of hydraulic technology and AI, its intelligent and wear-resistant performance will be further upgraded to promote the construction of ‘environmentally friendly mines’. The core advantages of roll crusher in the mineral processing industry are mainly reflected in its high efficiency crushing capacity, accurate particle size control, energy saving and environmental protection features and intelligent operation, etc. The following is the specific analysis: 1. High-efficiency crushing and precise particle size control Squeeze crushing mechanism Through the squeezing force, shear force and grinding force generated by the relative rotation of the double rolls, rapid crushing is achieved, with uniform discharged particle size (adjustable from 1-40mm) and significantly reduced over-crushing rate. The roll spacing can be flexibly adjusted by hydraulic system or shims to meet the requirements of particle size at different stages of beneficiation (e.g. coarse to fine crushing). Improved crushing efficiency With a processing capacity of up to 300 tonnes/hour, the crushing efficiency…

Sand Production Cost Of Sand Plant Is Too High Try To Use Roll Crusher

2025-08-03Sand Production Cost Of Sand Plant?For gravel plant operators, equipment maintenance is always a key factor affecting production efficiency. Traditional crushing equipment is often faced with fast wear and tear and frequent replacement of spare parts when processing materials in continuous operation, which not only increases the production cost, but also seriously affects the continuous operation of the production line. Durable crushing solution In response to this industry pain point, we have launched a new generation of roll sand making equipment, whose working method and structural design bring a brand-new production experience for sand and gravel plants. The roller crusher adopts the extrusion crushing method, and the material is gradually crushed by two rollers rotating in opposite directions. This working mode avoids the high-speed impact of traditional equipment, which fundamentally reduces the wear and tear of wearing parts. The equipment is equipped with high wear-resistant rollers, which are treated with multiple strengthening processes and have wear-resistant characteristics. Even if processing hard rock for a long time, it can still maintain good working condition. The roller crusher is equipped with a convenient gap adjustment device, the operator can quickly adjust the discharge size according to the production demand, to meet the…