Roller Stone Crusher: Robust, Simple Rock Processing

2025-12-26The roller stone crusher excels in tough rock-crushing scenarios with its mechanical simplicity and operational reliability. Unlike complex cone or impact crushers, its core design has fewer moving parts—meaning easier maintenance, less downtime, and lower long-term operating costs. It handles a wide range of materials steadily: granite, basalt, recycled concrete, you name it—delivering consistent throughput for your operation. It also works well with slightly damp or sticky feed, with little risk of clogging—boosting its versatility on-site. Huashengming (Zhengzhou, China) engineers these crushers for durability. They’re built to last, so your investment keeps delivering value through years of heavy use. Need a reliable, low-maintenance crusher for rock processing? Reach out to our team to find the right model for your project.

Mineral Crushing Industry

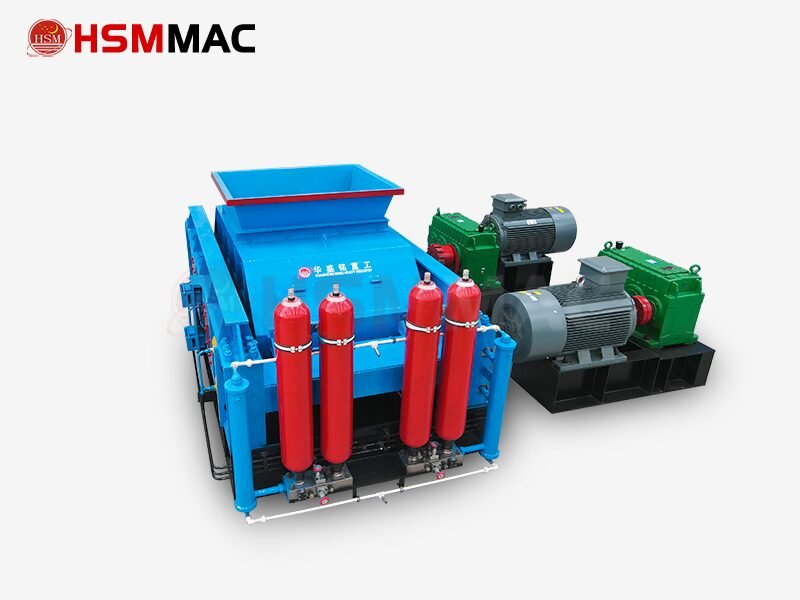

2025-12-26Efficiency, durability and cost-effectiveness are crucial in mineral processing. The hydraulic roller crusher stands out for its excellent performance and versatility, becoming a must-have for modern plants. Let’s explore its key features. What is a Hydraulic Roller Crusher? As the name suggests, a hydraulic roller crusher is a type of crushing equipment that uses two or more rotating rollers to squeeze and crush materials. Unlike traditional crushers that rely on impact or compression alone, this crusher combines the advantages of squeezing, shearing, and grinding, making it ideal for processing a wide range of minerals, from soft coal and limestone to hard granite and basalt. The core highlight of this equipment lies in its hydraulic system. This system controls the gap between the rollers with high precision, ensuring consistent particle size of the crushed products. Moreover, it provides overload protection — when uncrushable materials (such as metal debris) enter the crushing chamber, the hydraulic system automatically adjusts the roller gap to let the debris pass, avoiding damage to the equipment. Key Advantages of Hydraulic Roller Crusher in Mineral Crushing Its unique advantages make it superior to other crushers: 1. Superior Crushing Efficiency & High Output Adopting continuous crushing, it reduces energy…

Mineral Crusher Machine: Integrating a Roller Crusher into Your System

2025-12-25A complete mineral processing plant relies on correctly sequenced equipment. As a versatile mineral crusher machine, the Roller Crusher plays a vital role in this integrated system. It efficiently bridges primary crushing and final grinding stages, preparing a well-sized, consistent feed that maximizes the performance of downstream mills and separators. Huashengming provides comprehensive system support, ensuring our Roller Crushers are perfectly matched to your primary crushers and overall plant flow. Whether your operation focuses on aggregates, industrial minerals, or specific metal ores, we engineer our machines in Zhengzhou for seamless integration, durability, and the precise output your process requires for maximum profitability. Planning a new plant or optimizing an existing circuit? Let our experts integrate a high-performance Roller Crusher into your system. Contact Huashengming for a consultation.

Simplified Working Principle

2025-12-25The double roll crusher is a compact, efficient crushing device widely used in mining, cement, and aggregate processing. It’s favored for uniform product size, low over-crushing rate, and good adaptability to sticky materials. Below is a simplified breakdown of its working principle. Core Components Key parts ensuring stable operation: Crushing Rollers: Core parts (smooth/toothed) made of wear-resistant materials. Drive Device: Motors + reducers/gears, driving rollers to rotate oppositely. Adjustment Device: Wedge/gasket/hydraulic type, controlling discharge size via roller gap (1-50mm). Overload Protection: Spring/hydraulic cylinders, protecting equipment from unbreakable foreign objects. Feeding & Discharging Devices: Ensure uniform feeding and smooth material transfer. Simplified Working Process The crusher works based on “extrusion + shearing”, with 4 key steps: 1. Material Feeding Bulk materials (coal, limestone, etc.) are evenly fed into the gap between the two rollers (crushing chamber). 2. Roller Crushing Driven by the transmission system, the two rollers (one fixed, one movable) rotate oppositely. Materials are crushed by extrusion (and shearing for toothed rolls) to break along internal weak structures. 3. Overload Protection If foreign objects enter, the protection device retracts the movable roller to discharge them, then resets automatically. 4. Controlled Discharging Crushed materials meeting size requirements are discharged. Adjust the…

Roller Sand Making Machine: Your Solution for Challenging Feed Materials

2025-12-24Processing difficult materials like slightly moist, clay-bearing, or sticky aggregates often leads to clogging and downtime in conventional crushers. The Roller Sand Making Machine is specifically engineered to overcome these challenges and ensure continuous, reliable production. The machine’s crushing principle provides a natural advantage in handling adhesive feed. Its rolling and compressive action is less susceptible to material buildup and blockages, maintaining steady throughput where other systems may falter. This capability ensures a consistent supply of high-quality sand to your batch plant, even with variable feed conditions. This robustness makes it an indispensable component in complete processing plants. Paired with a primary crusher and effective screening, the Huashengming Roller Sand Making Machine reliably delivers the final, high-value product. Built with wear-resistant alloys in our Gongyi facility, it is made for durability and sustained performance in tough applications. Solve your most persistent material handling problems. Contact Huashengming to discuss a roller crusher solution tailored to your specific feed challenges.

What is a Double Roll Crusher? A Heavy-Duty Solution for Large-Scale Industrial Size Reduction

2025-12-23In high-volume industrial workflows (mining, cement production), a double roll crusher is a precision tool for bulk material sizing. It uses two wear-resistant, tandem-rotating rollers to apply steady extrusion force, delivering uniform particle sizes critical for downstream processes. Key High-Volume Uses Mining: Processes ores (iron, lithium) to meet beneficiation’s strict granularity rules. Cement production: Crushes limestone into consistent fragments, speeding kiln processing and cutting energy waste. Wet material handling: Handles wet coal without clogging—unlike impact crushers. Core Advantages High throughput: Up to 500 tons/hour (model-dependent), fitting large-scale lines. Longevity: Reversible rollers double wear life, reducing replacement costs. Minimal downtime: Simple design enables fast on-site repairs. For reliable bulk processing, Huashengming’s industrial roll crusher delivers the consistency high-volume operations need.

the Difference Between a Grinder and a Crusher

2025-12-23Grinders and crushers, common in workshops, kitchens and mines, both reduce material size but differ in purpose, mechanism and application. Below are their key differences to help you choose the right one. 1. Core Purpose: Coarse vs. Fine Reduction Crushers handle primary, coarse reduction: they use brute force to break large materials (boulders, concrete, metal scraps) into manageable chunks. Grinders focus on fine/ultra-fine reduction, refining small materials (or crusher output) into uniform powder, granules or paste with precision—e.g., grinding coffee beans or wheat. Crushers prioritize raw power to tackle oversized hard materials, with coarse output like gravel. Grinders prioritize precision over power, ensuring consistent small particle sizes for refined products. 2. Working Mechanism: Force vs. Abrasion Crushers rely on impact, compression or jaw pressure—common types include jaw (squeezing), cone (compressing) and impact (shattering via hammers) crushers, breaking materials with intense force. Grinders use abrasion, shearing or cutting via moving parts (blades, burrs, wheels), with types like burr (coffee/spices), angle (metal/stone) and ball mills (industrial powder), focusing on precision refinement. No detailed grinding is involved in crushers, while grinders refine to specific particle sizes. 3. Input & Output Crushers take large inputs (boulders, concrete slabs) and produce coarse fragments (≥1cm). Grinders…

How does a roll crusher work?

2025-12-22The Basic Principles Explained A roll crusher operates through two parallel cylindrical rolls rotating inward towards each other. Material is fed into the gap between these rolls, where it is drawn in by friction and subjected to compressive force. As the rolls rotate, the material is progressively crushed until small enough to pass through the adjustable gap, determining the final product size. Key Working Mechanism: Material enters the top of the crushing chamber Counter-rotating rolls draw material downward Progressive compression breaks material into smaller pieces Crushed product exits through the bottom gap This simple yet effective mechanical process makes roll crushers ideal for secondary and tertiary crushing where controlled size reduction is essential. Interested in implementing this technology? Contact Huashengming for professional roll crusher solutions from Zhengzhou, China.

The Best Crusher for Quality Recycled Concrete: The Roller Crusher Advantage

2025-12-21For projects demanding high-quality recycled concrete aggregates with minimal environmental impact, the Roller Crusher is the optimal selection. Its closed-chamber, low-speed compression crushing generates significantly less noise and airborne dust than high-impact methods, supporting compliance with strict worksite environmental and community standards. More importantly, the quality of the crushed material is superior. The roller crusher excels at producing clean, well-shaped aggregate by effectively separating the hardened cement paste from the natural aggregate. This results in a stronger, more durable recycled product suitable for high-value applications like road base or drainage layers. By choosing a roller crusher, you invest in a process that prioritizes both the quality of the end product and the sustainability of the operation. Produce premium recycled concrete responsibly. Partner with Huashengming, a leading manufacturer from China’s industrial hub, to implement a clean, efficient Roller Crusher system in your recycling flow.

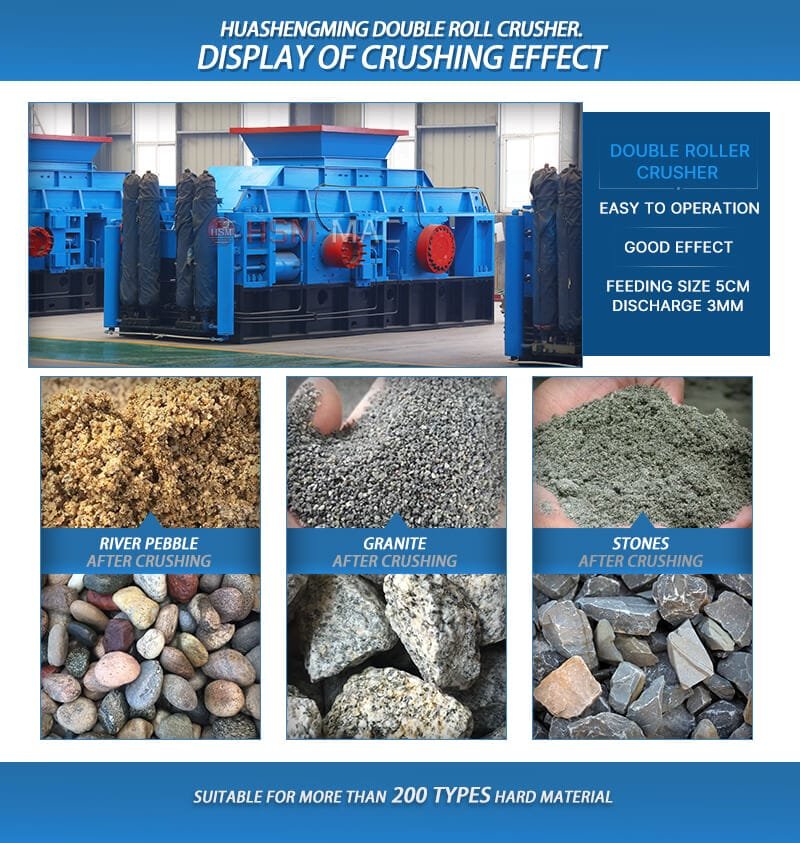

Rock Crushing Eco-Friendly Crusher: Double Roll Crusher

2025-12-18Amid growing global focus on environmental protection and stricter green production standards across industries, the crushing equipment sector is evolving rapidly. Traditional crushers are being phased out due to high energy consumption, heavy pollution, and low efficiency. Today, we introduce a star product in green crushing: the hydraulic double roll crusher, a high-performance eco-friendly device integrating efficiency, environmental protection and stability. What Makes Hydraulic Double Roll Crusher an “Eco-Friendly Star”? Unlike conventional crushers, the hydraulic double roll crusher is designed with environmental protection at its core, boasting significant advancements in noise reduction, dust control, and energy efficiency. Here are its key eco-friendly features: First, low-noise operation. Its advanced hydraulic transmission system and optimized roller design ensure gentle material crushing, avoiding the loud noise from traditional crushers’ violent collisions. With noise levels below 75dB (well under national industrial standards), it enhances workshop conditions and minimizes noise pollution. Second, efficient dust control. Dust is a major issue in crushing, but this crusher features a fully enclosed system (from feed to discharge) to prevent leakage. A matching high-efficiency dust collector captures over 99% of fine dust, protecting workers’ health and reducing air/soil pollution. Third, energy conservation. Its hydraulic system offers stepless speed control…

5 Major Advantages of Our Roller Crusher for Lithium Ore Crushing

2025-12-18Maximize the value and recovery of your lithium resources by integrating a Huashengming Roller Crusher. Here are the five key advantages it offers as a dedicated lithium ore crusher: Minimized Over-Crushing & Slimes Generation: The compressive crushing action significantly reduces the creation of ultra-fines (<0.075mm), protecting lithium mineral surfaces and improving recovery rates in subsequent separation stages. Precise Product Size Control: An easily adjustable roll gap allows for exact calibration of output size, producing consistent feed ideal for grinding circuits or direct beneficiation processes. Selective Liberation of Minerals: Promotes breakage along natural grain boundaries, leading to cleaner liberation of spodumene or lepidolite from gangue, which enhances concentrate grade. Lower Operating Costs: Energy-efficient compression crushing consumes less power than impact crushing. Combined with durable, long-lasting wear parts, it delivers a lower cost per ton. High Reliability & Easy Maintenance: Simple and robust design ensures high availability in remote mining locations, with easier and faster maintenance routines compared to more complex crushers. Ready to enhance your lithium processing efficiency? Contact Huashengming for a detailed consultation on our Roller Crusher solutions.

Jaw Crushers: The Primary Choice for Construction Waste Processing

2025-12-17Jaw Crushers are the optimal primary crushing solution for construction waste sand making machine production lines, offering key advantages for processing demolition materials. Core Advantages: 1.Wide Material Adaptability With large feed openings and deep crushing chambers, they directly process oversized concrete and masonry blocks (>800mm) down to a uniform size (≤150mm), reducing load on subsequent stages. 2.Robust & Reliable Design The compression crushing principle and high-rigidity frame withstand impacts from rebar and hard inclusions. Highly wear-resistant jaw plates ensure durability in continuous operation. 3.Cost-Effective Operation They deliver stable capacity with adjustable output size, featuring lower initial investment and operating costs compared to alternative primary crushers. 4.Seamless Process Integration Their discharge size perfectly matches the feed requirements of secondary crushers, streamlining the layout and improving overall efficiency of your construction waste sand making machine plant. Looking to build a reliable foundation for your recycling operation? Contact us to discuss how a Huashengming Jaw Crusher can optimize your construction waste sand making machine production line.