Coal Crusher

Coal Crusher

Coal is a carbon-containing fossil fuel, mainly formed from plant residues through millions of years of geological processes. It is one of the most important energy sources on Earth, widely used in ……

- Feed size: 80-1050mm

- Productive capacity:7-300t/h

- Application:Construction waste, pebbles, bluestones, limestone, granite, basalt and other materials that need to be moved.

- Application scope: It is suitable for crushing of raw coal (gangue containing) in coal, metallurgy, mining, chemical industry, building materials and other industries

Coal is a carbon-containing fossil fuel, mainly formed from plant residues through millions of years of geological processes. It is one of the most important energy sources on Earth, widely used in power gene ration, industrial production, and heating, among other fields. The coal crusher is a special equipment used for coal crushing. It consists of two drums equipped with gears, which crush coal by rotating the drums and applying pressure.

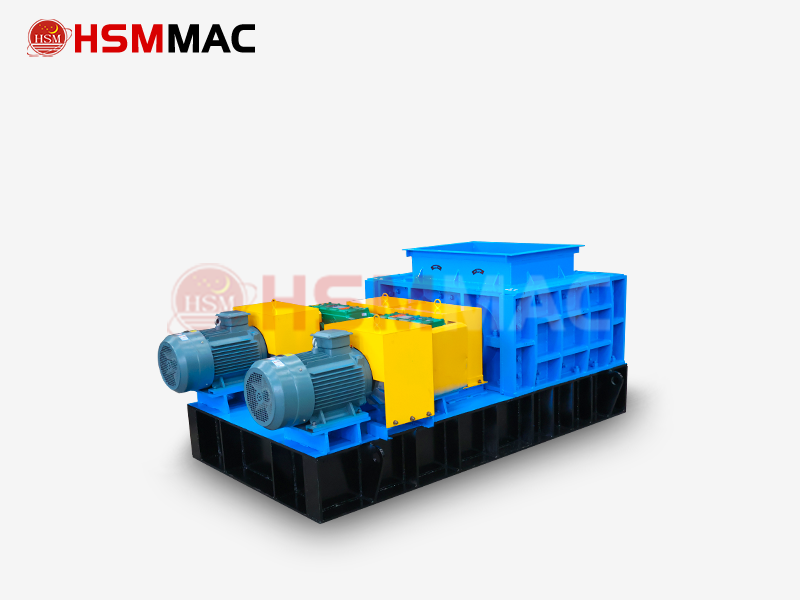

What is Coal Crusher

The coal crusher adopts the principle of double-roller crushing and extrusion, breaking the raw material through coarse crushing and fine grinding to achieve the required particle size.Coal Crusher is mainly used in mining, metallurgy, chemical industry, coal mine to crush coarse, medium size fragile material. Its feeding size is big, discharging size is adjustable. it can crush material of compressive strength below 160Mpa.

Especially in coal industry, double teeth roll crusher can crush raw coal and coke directly after removing iron and impurity, no need to remove gangue. crushed material is uniform granularity, low over crushing ratio. it simplified coal selecting process, reduced investment and production cost. Double teeth roll crusher can be equipped with coarse or medium sized teeth rollers according to material characteristics and requirements.

Working principle

The Coal Crusher uses two wear-resistant alloy toothed rollers to break materials under high extrusion pressure generated by relative rotation. After the materials enter the gap between the two toothed rollers (V-shaped crushing chamber), the materials are broken into the required particle size and then sent out by the conveying equipment under extrusion, shearing and grinding.

| Model | Roller diameter (mm) |

Roller length (mm) |

Max feeding size (mm) |

Discharging size (mm) |

Capacity (t/h) |

Motor power (kw) |

Weight (kg) |

Dimension (L×W×H) |

| 450×500 | 450 | 500 | 200-500 | 15-100 | 30-60 | 7.5×2 | 3800 | 2260×2200×766 |

| 600×750 | 600 | 750 | 300-600 | 20-120 | 60-100 | 11×2 | 7200 | 2780×3065×1310 |

| 600×900 | 600 | 900 | 300-600 | 30-150 | 80-120 | 18.5×2 | 7800 | 4500×1900×1350 |

| 800×1050 | 800 | 1050 | 500-800 | 30-150 | 100-160 | 22×2 | 12600 | 2550×2050×1100 |

| 900×900 | 900 | 900 | 600-900 | 30-200 | 150-200 | 22×2 | 13500 | 2780×4100×1550 |

| 1015×760 | 1015 | 760 | 700-950 | 30-200 | 150-200 | 45×2 | 18800 | 7800×3200×1980 |

| 1200×1500 | 1200 | 1500 | 800-1050 | 30-200 | 200-300 | 55×2 | 52000 | 8010×4500×2050 |