20 tph stone crusher

Processing gold-bearing ore effectively demands crushing technology that prioritizes mineral liberation over simple size reduction. In this context, a roller crusher serves as an excellent choice for secondary or tertiary stages in a gold recovery circuit. Its core principle of applying controlled compressive force between two heavy-duty rolls is particularly suited for many gold ores.

This method delivers significant advantages for gold processing. The roller crusher produces a more uniform product with a minimized proportion of ultra-fines (“slimes”). Excessive fines can encapsulate fine gold particles, hindering gravity separation or cyanide leaching efficiency. By generating a well-graded, granular feed, this equipment promotes cleaner mineral exposure. Furthermore, its adjustable gap allows operators to fine-tune the output size to match the optimal feed specification for your downstream ball mill or concentrator, creating a more efficient and controlled preparation stage that maximizes recovery potential.

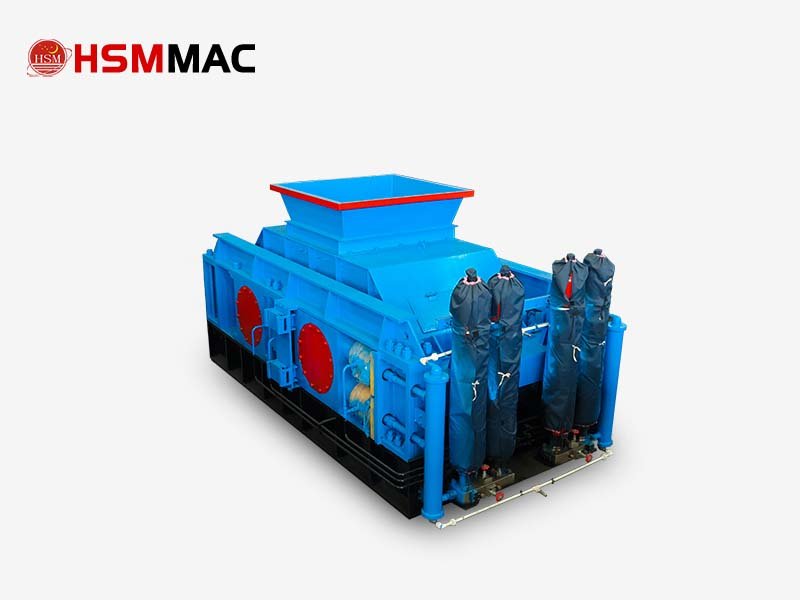

Roller Crusher

Optimize your comminution circuit for better gold liberation. Inquire about integrating a precision roller crusher into your operation.