Basalt sand-making machine, also known as basalt double-roll crusher, is a crushing device that demonstrates numerous advantages in processing basalt. Designed specifically for the properties of basalt, this double-roll crusher offers exceptional quality and performance benefits, making it highly popular among basalt processing plants. Below is a brief introduction to the working principle, structure, and performance characteristics of this basalt double-roll crusher.

basalt sand making machine

1. Structural Composition

The basalt double-roll crusher primarily consists of a frame, crushing rolls, transmission mechanism, adjustment device, and spring safety device. Its overall structural design is exceptionally simple, innovative, and distinctive, featuring a high degree of automation. Operation and maintenance tasks are straightforward and convenient.

2. Working Principle

The basalt double-roll crusher feeds crushed basalt through the inlet into the space between two rolls, where it undergoes compression crushing. Finished material then falls naturally. When encountering excessively hard or uncrushable material, the rollers automatically retreat via hydraulic cylinders or springs, widening the gap to allow the foreign object to pass, thereby protecting the machine from damage. The counter-rotating rollers maintain a controlled clearance; adjusting this gap regulates the maximum discharge particle size.

3.Performance Advantages

Iron-Pass Protection for Stable Operation

The basalt double-roll crusher is equipped with iron-pass protection, which not only prevents non-crushable objects from entering the machine and damaging the equipment but also ensures stable operation without incidents such as vibration or shutdowns.

Reliable Quality and Extended Service Life

Key working components like the rollers are cast from ultra-wear-resistant materials with high toughness. They exhibit excellent wear resistance, corrosion resistance, and high-temperature tolerance. This extends the replacement cycle for wear parts, ensuring long-term reliability and extended operational lifespan.

Multi-Functional and Flexible Adaptability

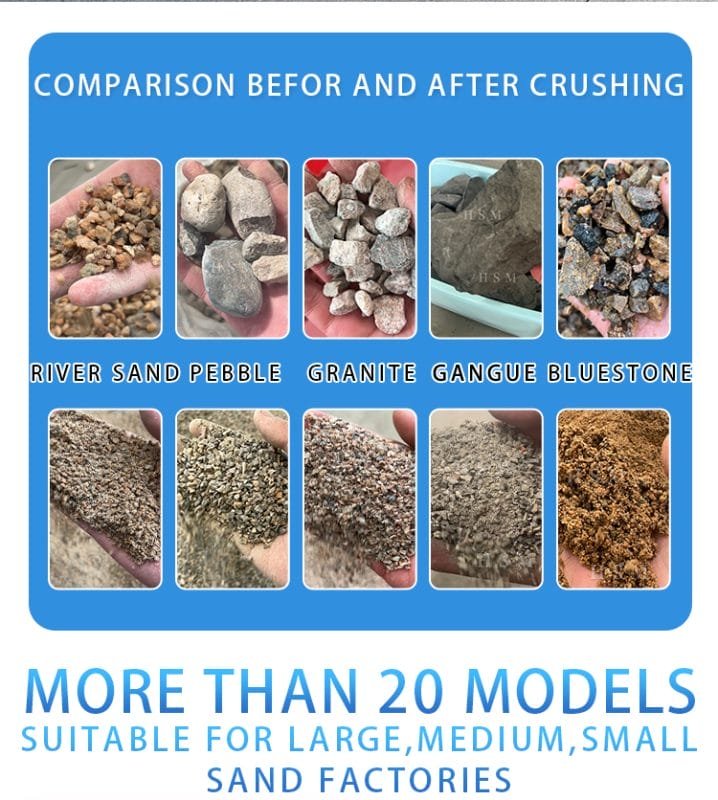

This equipment not only crushes basalt but also efficiently screens the crushed material. It operates effectively regardless of basalt particle size, hardness, or moisture content. Material particle size can be adjusted according to user production requirements, offering highly flexible and convenient adaptability.

Low Dust, Eco-Friendly & Safe

The equipment incorporates advanced dust suppression, noise reduction, and explosion-proof systems. This ensures minimal dust and noise pollution during basalt crushing while enhancing operational safety, achieving green, environmentally responsible, and secure production.