Hammer Crusher

Hammer Crusher

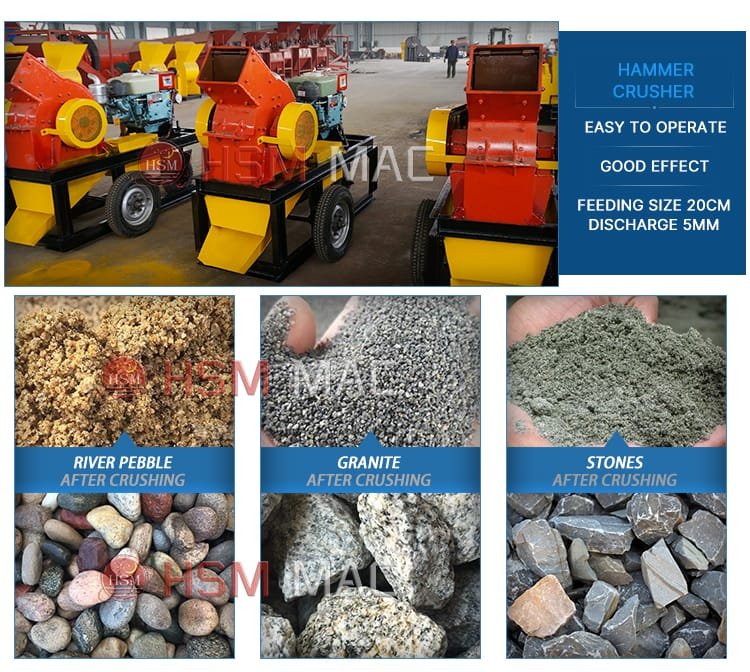

The hammer crusher (small hammer crusher) designed and produced by the manufacturing technology of Huashengming Heavy Industry is suitable for crushing minerals of various brittle materials. Hammer ……

- Feed size: ≤1500mm

- Productive capacity:5-280t/h

- Application:Coal, concrete, limestone, sandstone, quartz, calcite, glass, construction waste, slag, coke and other materials crushing and fine crushing operation

- Application scope: Used for crushing medium hardness materials in cement, chemical, electric power, metallurgy and other industrial sectors

The hammer crusher (small hammer crusher) designed and produced by the manufacturing technology of Huashengming Heavy Industry is suitable for crushing minerals of various brittle materials. Hammer crusher (heavy hammer crusher) is the direct particle size of 600-1800 mm material broken to 25 or 25 mm below a section of crushing crusher.

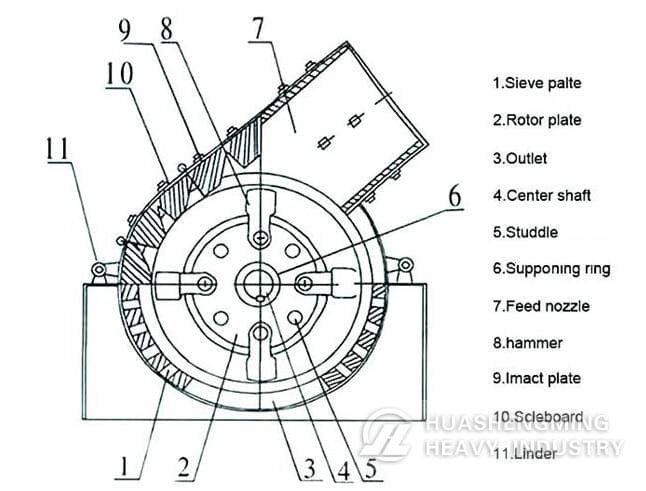

Working principle:

When the hammer crusher is working, the motor drives the rotor to rotate at high speed, and the material evenly enters the crusher cavity. The high-speed rotating hammer impacts and shear tears the material, causing the material to be broken. At the same time, the material’s own gravity makes the material rush from the high-speed rotating hammer to the baffle and screen in the body of the frame, at the lower part of the rotor. Provided with a sieve plate, the crushed material is smaller than the size of the sieve through the sieve plate discharge, larger than the size of the sieve to stay in the sieve plate continue to be hit by the hammer and grinding, until broken to the required discharge particle size through the sieve plate discharge machine.

| Model | Feeding size (mm) Max | Discharging size (mm) Max | Capaticy (t/h) | Motor power (kw) | Weight (kg) |

| PC200x300 |

≤100 |

≤20 |

1-5 |

5.5 |

500 |

| PC300x400 | ≤200 | ≤25 | 5-10 | 11 | 800 |

| PC310x520 |

≤200 |

≤25 |

8-15 |

18.5 |

1400 |

| PC600x400 | ≤250 | ≤30 | 10-22 | 22 | 2260 |

| PC800x600 | ≤250 | ≤35 | 18-40 | 55 | 4800 |

| PC1000x800 | ≤350 | ≤35 | 25-50 | 75 | 5900 |

| PC1000x1000 | ≤350 | ≤35 | 30-55 | 90 | 8000 |

| PC1250x1250 |

≤350 |

≤35 |

35-65 |

132 |

14000 |

| PC1400x1400 |

≤350 |

≤35 |

50-100 |

280 |

32000 |

| PC1600x1600 | ≤350 | ≤35 | 100-150 | 480 | 37500 |