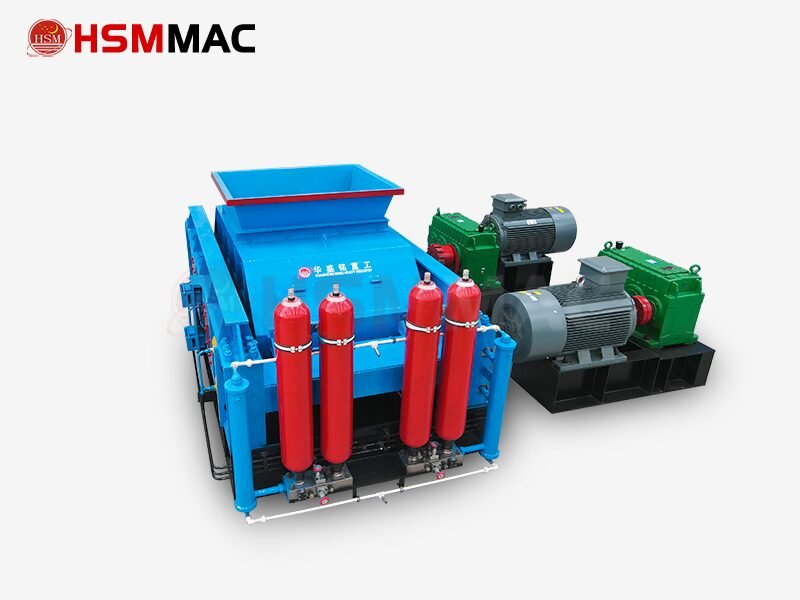

Huashengming Gold Rock Crusher (primarily a roller crusher) operates on the principle of dual-roller compression crushing combined with shear tensile action. Hydraulic or mechanical adjustment precisely controls the discharge particle size (1-50mm), making it particularly suitable for crushing high-hardness or high-moisture sticky materials such as muddy gold ore and granite.

Gold Rock Crusher

1. Core Crushing Principle

Synergistic Action of Compression and Shearing

Upon entering the gap between the two rollers, the material undergoes dual forces: high-pressure compression and serrated shearing:

Compression Crushing: The two rollers rotate in opposite directions (with a designed speed differential), applying sustained high pressure to the material, causing the rock to fracture along its weak joints.

Shear Tension: The serrated roller surfaces (e.g., wolf teeth, wave teeth) enhance shear forces on the material. This is particularly effective for sticky particles in muddy gold ore, where tension strips away the clay layers enveloping gold grains.

This synergistic action significantly reduces over-crushing rates (<10%) and improves gold ore leaching efficiency.

Simultaneous Particle Size Classification

Certain models (e.g., high-efficiency classification crushers) incorporate direct screening through inter-tooth gaps during crushing. Qualified particles are rapidly discharged, while oversized particles are returned for re-crushing, preventing pulverization from repeated crushing.

2. Particle Size Control Mechanisms

Hydraulic/Spring Adjustment System

Adjustment Method: Dynamically adjusts roller gap (0-50mm range) via hydraulic cylinders or spring mechanisms with ±0.1mm precision.

Particle Size Control:

Narrowing gap → Finer output size (e.g., 1-3mm fine sand)

Widening gap → Coarser output size (e.g., 40mm aggregate)

Hydraulic models support AI real-time monitoring of material properties, automatically optimizing roll gap parameters to ensure over 95% of finished products meet target particle size.

Wedge/Shim-Assisted Adjustment

Some lower-spec models use mechanical adjustment:

Wedge mechanism: Bolt-controlled wedge block elevation indirectly alters roll distance;

Shim mechanism: Adjust gap by adding/removing shims or altering their thickness.

3. Wear Resistance & Protection System

Three-Layer Composite Roll Shell Technology

Structural Design: Outer layer of high-chromium alloy (hardness HRC60+) + middle layer of high-manganese steel + bottom layer with dovetail groove locking substrate;

Lifespan Advantages: Wear resistance 3 times higher than standard steel, processing capacity exceeding 30,000 tons, lifespan >2 years (in high-abrasion environments like gold mines).

Overload Protection Mechanism

Hydraulic Automatic Retreat: Upon encountering rebar or non-crushable objects, the hydraulic system instantly releases pressure, causing the rollers to automatically separate and evade;

Mechanical Safety Device: The jaw crusher’s toggle plate design fractures during overload, protecting core components.

4. Wet Material Adaptability Design

Screenless Anti-Blocking Structure

The dual-tooth roller model eliminates traditional screens. Spiral-arranged tooth rollers enhance wet material grip, enabling direct crushing of clay-rich gold ore with moisture content ≤15% and near-zero blockage.

Scraper Self-Cleaning System

Alloy scrapers mounted on roller surfaces continuously remove adhering clay, preventing “roller wrapping.”

5. Intelligent Control System (High-Spec Models)

AI Dynamic Adjustment

Real-time monitoring of material hardness, moisture content, and feed rate enables automatic adjustment of roll gap, rotational speed, and motor power, reducing energy consumption by 25%.

Remote Monitoring and Early Warning

Supports mobile device-based start/stop operations and parameter adjustments;

Fault early warning (e.g., 72-hour advance alerts for abnormal bearing temperature rise).