Molybdenum ore is the most important mineral raw material for refining molybdenum. With a specific gravity of 4.7-4.8, a hardness of 1-1.5, and a melting point of 795°C. Molybdenum ore refining molybdenum needs to go through crushing, grinding and beneficiation processes. Huashengming Heavy Indus……

Molybdenum ore is the most important mineral raw material for refining molybdenum. With a specific gravity of 4.7-4.8, a hardness of 1-1.5, and a melting point of 795°C. Molybdenum ore refining molybdenum needs to go through crushing, grinding and beneficiation processes. Huashengming Heavy Industry shares a complete set of beneficiation process, crushing equipment and a complete set of crushing production line for molybdenum ore!

Jaw crusher

Jaw crusher: it is suitable for initial crushing, handling large ores (feed size ≤1200mm). With the advantages of simple structure and large processing capacity.

Hammer crusher

Hammer crusher: for high hardness ores containing more rigid materials, with high crushing efficiency and less dust.

Cone crusher

Cone crusher: for medium to high hardness ores, adopting hydraulic control system and adjustable discharge size.

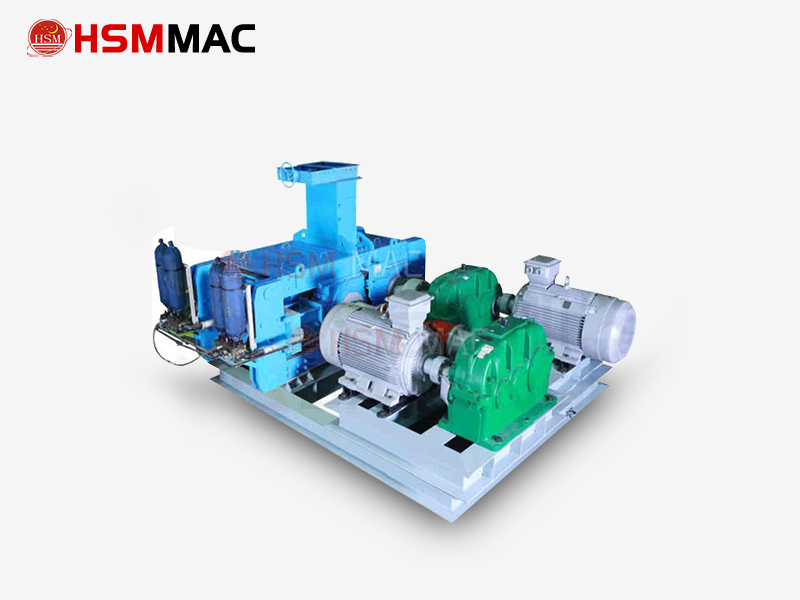

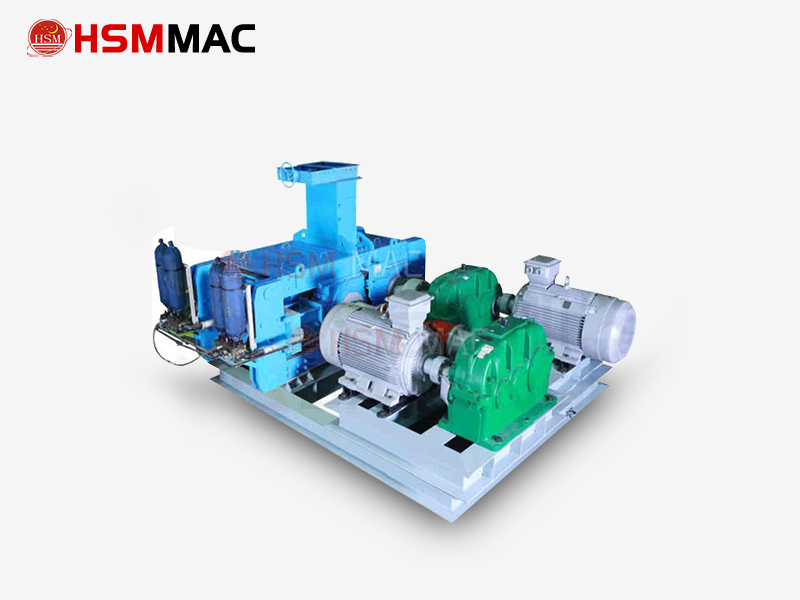

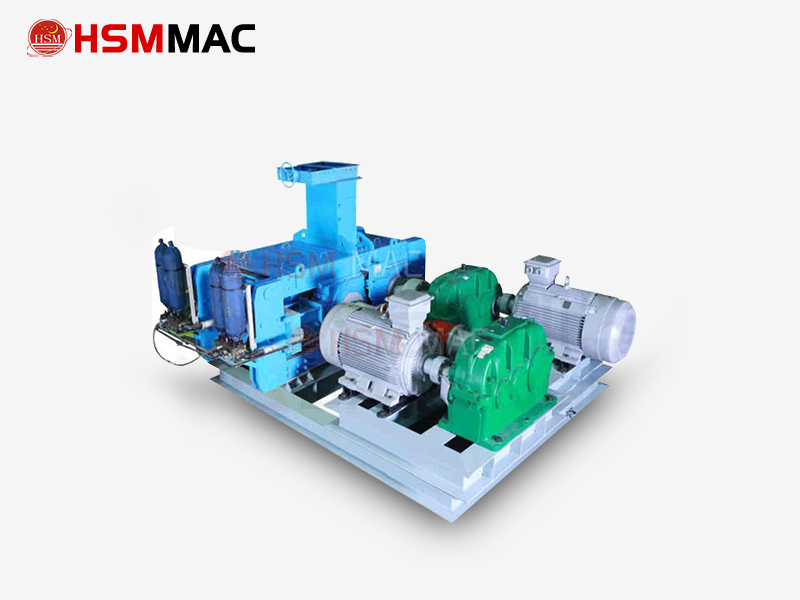

High-pressure roller mill

High-pressure roller mill: used for ultra-fine crushing or pre-grinding, reducing subsequent grinding energy consumption through laminated crushing (closed circuit process product P80 can be reduced to 1.6mm).

Vertical agitator mill: used in conjunction with high pressure roller mill to replace the traditional ball mill. Energy saving 14.9%~19.5%, suitable for processing 3~5mm closed circuit products.

Ball mill

Ball mill: If traditional process is adopted, it is recommended to configure hydraulic drive system to reduce energy consumption (e.g. φ5.03m×6.40m ball mill with installed power of 3200~4500kW).

About molybdenum ore crushing equipment selection and production line configuration if you want to know the specific content, you can always leave a message!