5 Core Advantages: Double-Roll Crusher for River Pebble Crushing

2025-12-06Double-roll crushers are well-suited for river pebble crushing, thanks to their unique working principle and structural design. Here are their key advantages: 1. High Adaptability to Hard Materials Adopting low-speed extrusion crushing, it makes river pebbles break along natural cracks. Equipped with wear-resistant alloy roller skins, it effectively resists the abrasiveness of river pebbles, reducing equipment wear and ensuring stable operation. 2. Excellent Finished Product Quality The particle size can be precisely controlled by adjusting the roller gap. The finished aggregates are mostly sub-angular or near-cubic, with low flakiness content and continuous gradation, meeting the requirements of construction scenarios such as concrete mixing. 3. Energy-Saving and Cost-Effective Compared with impact crushers, it operates at a lower speed with less energy consumption. The structure is simple, with fewer wearing parts that are easy to replace, minimizing daily maintenance workload and long-term operating costs. 4. Safe and Eco-Friendly Operation Without high-speed rotating components, it runs smoothly with low noise, suitable for production sites near residential areas. The sealed crushing cavity reduces dust leakage, complying with environmental protection requirements for green production. 5. Reliable and Easy to Maintain It has a built-in overload protection system. When encountering uncrushable foreign objects, the roller can…

Jaw Crusher vs. Roll Crusher: Key Differences

2025-12-05Jaw Crusher vs. Roll Crusher. Wondering which crusher fits your needs? Let’s break down the core differences between jaw crushers and roll crushers. 1. Core Structure Jaw Crusher: Has a fixed jaw and a movable jaw (like a “jaw” shape) that moves back and forth. Roll Crusher: Features 2–4 rotating rolls (smooth or toothed) that work in pairs. 2. Crushing Principle Jaw Crusher: Uses “compression crushing” — the movable jaw squeezes materials against the fixed jaw to break them. Roll Crusher: Relies on “shearing & squeezing” — rotating rolls grab and crush materials between them. 3. Suitable Materials Jaw Crusher: Ideal for hard/abrasive materials (granite, basalt, ore) — great for primary crushing. Roll Crusher: Better for medium-soft materials (coal, limestone, clay) — often used for secondary crushing. 4. Final Product Jaw Crusher: Output has irregular shapes; particle size varies more. Roll Crusher: Produces uniform, cubical particles with less dust — good for strict size requirements.

Cement Sand Making Machine: Complete Crushing Process Guide

2025-12-05—— High-Efficiency Configuration Scheme of Jaw Crusher + Impact Crusher + Roller Crusher + Ball Mill Cement Sand Making Machine focuses on “precision crushing + high-efficiency grinding” in its core process. Adopting the combined configuration of Jaw Crusher, Impact Crusher, Roller Crusher and Ball Mill, it ensures cement aggregate quality meets standards. The streamlined process is as follows: 1. Primary Crushing: Pretreatment & Load Reduction Use a Jaw Crusher to crush large raw materials (e.g., limestone, dolomite) of 500-1000mm down to 100-300mm, removing soil and impurities. 2. Secondary Crushing & Shaping: Particle Size Optimization Complete secondary crushing with an Impact Crusher, reducing materials to 30-80mm and optimizing particle shape. 3. Roller Crusher Fine Crushing: Precision Particle Size Control Feed secondary crushed materials into the Roller Crusher, crushing them to below 5mm via extrusion with regular particle shape and low over-crushing rate. 4. Ball Mill Grinding: Qualified Fine Powder Production Finely crushed materials enter the Ball Mill, ground to 80-400 mesh fine powder for cement hydration requirements. 5. Screening & Circulation: Quality Control Classify via a Vibrating Screen; qualified powder is stored, unqualified particles reprocessed for uniform finished products. The process suits medium-low hardness materials with smooth equipment connection, enabling efficient…

Hammer vs. Roller Crushers: Quick Guide

2025-12-04Hammer vs. Roller Crushers . Need to choose fast? Here’s the core lowdown with key details: How they work: Hammer crusher: High-speed rotating hammers deliver intense impact to shatter materials instantly. Roller crusher: Two counter-rotating rollers apply gradual squeezing pressure to crush materials evenly. Best for: Hammer: Brittle/soft materials (coal, limestone, gypsum) – handles medium-fine crushing needs. Roller: Hard/sticky materials (ore, gravel, clinker) – avoids clogging with viscous substances. Output: Hammer: Irregular-shaped particles with more fine dust; ideal for final crushing stages. Roller: Uniform cubical grains with minimal fines; perfect for aggregate or construction-grade materials. Upkeep: Hammer: Higher maintenance – hammer heads wear quickly from impact, requiring regular replacement. Roller: Lower upkeep – durable roller surfaces resist wear, even with hard materials. Pro Tip Hammer = Fast, fine crushing for brittle, non-sticky materials. Roller = Stable, low-maintenance crushing for hard/sticky loads needing consistent particle size. Got questions about specific projects? Drop a comment below!

Blue Quartz Sand Making? Just Choose Roller Crusher!

2025-12-04Facing challenges in blue quartz sand making? The blue quartz sand making machine from Hua Shengming—our specialized Roller Crusher—precisely addresses pain points like high-hardness-induced wear, substandard particle shape, and excessive powder content. It completes the entire production process in one unit, making blue quartz sand making efficient and hassle-free! 1. Tailored to Blue Quartz Properties As a high-hardness, high-purity ore, blue quartz demands durable and precise processing equipment. Our Roller Crusher (blue quartz sand making machine) features a roller body crafted from wear-resistant materials (e.g., high-chromium alloy), withstanding intense friction to extend service life. Its “extrusion + shearing” crushing principle avoids over-crushing, yielding sand with uniform, rounded particle shape, low needle-like content, and controllable powder levels. 2. Flexible & Energy-Efficient Design Adjustable roller gap: Adapts to diverse specification requirements for multiple application scenarios. Energy-saving: More cost-effective than traditional impact sand making machines. Compact structure: Easy to maintain, small footprint, suitable for both small-scale test lines and large-scale production lines. 3. Global Support & Certifications Our blue quartz sand making machine (Roller Crusher) holds CE and ISO certifications, supporting global delivery, English technical documentation, and remote commissioning. We have provided stable equipment solutions for projects in Africa, Europe, Southeast Asia, and beyond. Choose…

Roller Crusher: The Powerhouse Behind Efficient Aggregate & Marble Lines

2025-12-01In the aggregate and marble sand making industry, a high-performance production line relies on core crushing equipment. This Roller Crusher, as a professional aggregrate and marble sand making machine, serves as the powerhouse of production lines, breaking efficiency bottlenecks with stable, integrated, and cost-effective performance. 1. Strong Core Power: Uninterrupted Production Guarantee Equipped with a high-power motor and hardened gearbox, the Roller Crusher delivers 50-500 tons/hour throughput, adapting to medium and large-scale lines. Its intelligent overload protection avoids shutdowns from impurities, ensuring 24/7 continuous operation and eliminating production interruptions. 2. Seamless Integration: Optimize Line Processes With a compact design, the Roller Crusher integrates seamlessly with feeding, screening, and conveying equipment. Adjustable feeding baffles match front-end output, while 0-5mm stepless adjustable discharge directly meets subsequent process requirements—reducing intermediate links and boosting line fluency. 3. Material-Targeted Crushing: Stable Finished Product Quality Adopting dual-roller extrusion and HRC60+ alloy rollers, it handles high-hardness aggregate (e.g., granite) and marble precisely. Finished products feature cubic shapes (powder content ≤3%) and 95% marble whiteness, ensuring high qualification rates and avoiding reprocessing. 4. Low-Consumption Operation: Cut Line Costs Energy consumption is only 5kWh/ton (30% lower than traditional models). The wear-resistant roller surface offers a 12-month maintenance cycle for…

Double-Roll Crushers Can Be Used As Ores For Copper And Gold Crusher

2025-11-190res for copper and gold crusher Also known as a double-roll crusher, it demonstrates outstanding performance in crushing copper and gold ore,with significant advantages particularly in the medium and fine crushing stages. 1. Core Competitive Advantage: ores for copper and gold crusher double-roll crusher Precise and Controllable Particle Size The roll gap is adjusted via a hydraulic system (accuracy ±1mm), enabling stable control of discharge particle size within 1-5mm. This meets the optimal particle size requirements for leaching/flotation processes. The over-crushing rate is **<10%, minimizing loss of fine metal particles and directly boosting recovery rates by 10%-15%. Wear-Resistant Durability & Low Maintenance Roll liners utilize high-chromium manganese steel + rare metal alloy (hardness HRC ≥ 60), delivering a service life exceeding 2 years—three times that of conventional equipment. Modular design enables rapid 1-hour replacement, cutting annual maintenance costs by 50%. Energy-efficient and eco-friendly Layer compression crushing consumes 30%-45% less electricity than impact crushers, with power consumption per ton of ore at just 0.8-1.2 yuan. The enclosed structure combined with pulse dust removal ensures dust emissions <10mg/m³and noise levels **≤75dB(A), meeting green mining standards. Multi-Material Adaptability Processes copper and gold ores (including quartz veins and other hard minerals) with compressive strength…

For Gravel Sand Making, Choose The Double-Roll Cobble Sand Making Machine.

2025-11-12Huashengming Heavy Industry’s pebble double-roll sand making machine comes in over 20 models ranging from large to small, with hourly output capacities from 2 to 450 tons. Prices range from 2 to 120, achieving a sand yield rate of 98%. The output particle size can be freely adjusted between 0.2 and 20mm. 1.Advantages and Features of cobble sand making machine Production Capacity: High efficiency with moderate output, meeting the needs of a wide range of users. Equipment Stability: Motor power ranges from 5.52KW to 1102KW, featuring low energy consumption, stable operation, and a failure rate as low as 0.01%. Output Particle Size: Produces uniform particle size with attractive shape, crucially containing minimal stone powder content to meet construction requirements. Pebble Sand Making Machine Performance Handles Materials with 8% Moisture Content: This capability is rare among other equipment. The pebble sand maker prevents clogging during crushing. Extended Spare Part Replacement Intervals: Huashengming pebble sand makers feature rollers made of highly wear-resistant materials and a robust, sturdy frame. Longer maintenance cycles reduce repair costs by 30%. 2.Cobble sand making machine Manufacturer — Huashengming Heavy Industry Customized Solutions: With over 30 years of practical experience and a dedicated R&D design and engineering…

Advantages Of Using A Double-Roll Crusher As A Glass Crusher

2025-10-28Glass is increasingly prevalent in our daily lives, offering properties such as hardness, airtightness, light transmission, chemical inertness, and sound insulation. Advantages of Using a Double-Roll Crusher as a Glass Crusher.The glass double-roll crusher is a specialized crushing equipment designedforglassprocessing. It features low operating and maintenance costs, minimal moisture requirements, reliable performance, reduced powerconsumption,lowdust generation,and quiet operation. 1. Glass Double-Roll Crusher Feed Size: 25-100mm Production Capacity: 2-400 t/h Applications Highways, high-speed railways, high-rise buildings, municipal projects, hydroelectric dam construction, concrete batching plants, sand and gravel quarries, etc. Suitable Materials River pebbles, calcite, quartzite, marble, cobblestones, bentonite, iron ore, bluestone, quarry rock, slag, limestone, weathered sand, diabase, granite, basalt, etc. 2.Working Principle The glass crusher performs crushing operations via roller wheels. Material enters between the rollers through the feed inlet and is crushed by squeezing action. A specific gap exists between the two rollers. Increasing this gap produces larger discharge particle sizes, while compressing the gap with tension springs reduces the discharge particle size. By adjusting the gap, the discharge particle size can be controlled. 3.Product Introduction

Large Ore Crusher A double-roll crusher may be used.

2025-10-27Large Ore Crusher A double-roll crusher may be used. The large double-roll crusher is specifically designed for large-scale crushing operations in the mining industry. featuring a heavy-duty structure and advanced hydraulic technology to efficiently process various hard ores. Its dual-roll surface delivers powerful compression crushing , ensuring a high crushing ratio and uniform particle size. The hydraulic system enables precise roll gap adjustment while incorporating overload protection, enhancing equipment stability and safety. Ideal for primary and secondary crushing of iron, copper, gold, and other ores, it serves as a critical piece of equipment for boosting mining productivity and resource utilization. 1. Large Ore Crusher Feed Size: 25-100mm Production Capacity: 2-400 t/h 2.Suitable Materials Highways, high-speed railways, high-rise buildings, municipal projects, hydroelectric dam construction, concrete batching plants, sand and gravel quarries, etc. 3. Working Principle Large ore crushers, specifically double-roll crushers, utilize two sets of independently driven roll shafts. These shafts rotate in opposite directions, generating squeezing, grinding, and shearing forces to break down materials. Material enters through the feed opening and falls between the rollers. After being crushed by the opposing rollers, the finished product naturally discharges. When encountering excessively hard or uncrushable material, the rollers automatically retreat via hydraulic…

This Milling And Planing Material Crusher Is Reliable.

2025-10-26Milling and Planing Material Crusher is a specialized piece of equipment designed specifically for crushing asphalt pavement. It primarily employs rotating toothed rollers to impact and shear the material, effectively breaking milled material into small, recyclable particles. Featuring a simple structure, high crushing efficiency, and low energy consumption, this equipment is widely used in road maintenance and renovation projects. The crushed milled material can be recycled for roadbed construction and base layer filling, conserving resources while reducing environmental pollution. 1.Milling and Planing Material Crusher Feed Size: 80-1050mm Production Capacity: 7-300 t/h Application Scope: Suitable for coal, metallurgy, mining, chemical, and building materials industries. Particularly effective for crushing raw coal (including gangue) in large coal mines or coal preparation plants. 2.Suitable Materials: Silicomanganese alloy, ferrosilicon alloy, industrial silicon, construction waste, milled material, silicate, coal gangue, coal, coke, asphalt blocks, high-calcium limestone, limestone, excavated material, etc. 3.Actual photo

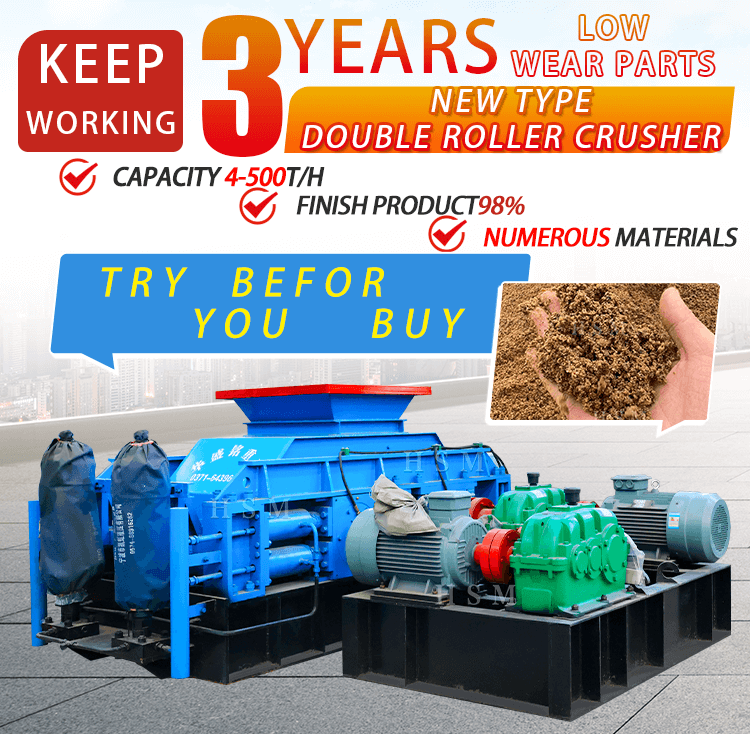

Discover the Advantages of Double Roll Crushers

2025-10-24The double-roll crusher represents another breakthrough in the manufacturing of sand and gravel aggregate production equipment. Also known as a twin-roll crusher or double-roll sand maker, it employs two motors to drive two sets of rollers that compress and grind materials. This machine is designed for fine crushing operations where the feed size is less than 80mm and the finished product requires a particle size of 50 mesh to 20mm. 1.Double Roll Crusher Feed Size: 25-100mm Production Capacity: 2-400 t/h Suitable Materials: River pebbles, calcite, quartzite, marble, cobblestones, bentonite, iron ore, bluestone, quarry rock, slag, limestone, weathered sand, diabase, granite, basalt, silicon carbide, emery, sintered bauxite, magnesia, etc. Application Scope: Highways, high-speed railways, high-rise buildings, municipal projects, hydroelectric dam construction, concrete mixing plants, sand and gravel yards, etc. 2.Actual Photo Over 20 models Meet the needs of large, medium, and small sand plants 3.Working Principle The double-roll crusher utilizes two independently driven roller shafts that rotate in opposite directions to generate crushing and grinding forces. Material enters through the feed opening and falls between the two rolls, where it is crushed by the opposing rollers before the finished product naturally discharges. When encountering excessively hard or uncrushable material, the rollers…