Pursuing high-quality crushing effect and efficient operation capacity, double-tooth roll crusher is really an ideal equipment for processing milling material, which is worth considering and trying. This kind of equipment generates high squeezing pressure through two relatively rotating wear-resistant alloy rolls, which can effectively achieve large crushing ratio, and at the same time reduce the phenomenon of over-powder to ensure that the particle size of the crushed recycled material meets the construction requirements.

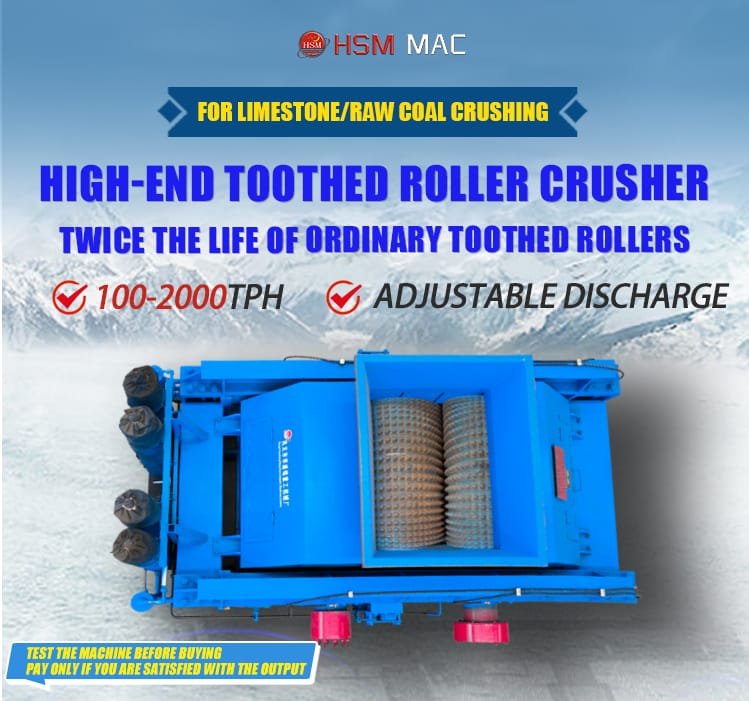

Double-toothed roll crusher is a kind of roll crusher with teeth on the round roll, which has the advantages of small volume, large crushing ratio, low noise, simple structure, convenient maintenance, uniform size of crushed materials, low overcrushing rate, sensitive overload protection, safety and reliability. It is widely used in coal, metallurgy, mining, chemical industry, building materials and other industries, and is more suitable for crushing raw coal in large coal mines or coal preparation plants. The use of mechanical, electrical, hydraulic and other multiple protection devices and interlocking devices, the motor and reducer with a distance-limiting type hydraulic coupling coupling, to prevent power overload, sensor overload protection, safe and reliable, but also effectively protect the motor.

Double tooth roll crusher is an excellent choice for processing milling material, especially for asphalt pavement milling material.

The advantages of double toothed roll crusher are:

1, high efficiency and stability:

double-toothed roll crusher not only has high crushing efficiency, but also runs stably and is suitable for continuous operation, which is especially important for large-scale milling material processing projects.

2, full particle size, less powder:

the output of recycled material full particle size, less powder, which helps to improve the quality and stability of recycled asphalt mixture, thus improving the performance of recycled road surface.

3, wear-resistant and durable:

the use of wear-resistant alloy roller skin, significantly improving the durability of the equipment, reducing maintenance costs and downtime.

4、Wide range of application:

the single machine has a wide range of hourly output, from 5 tonnes to 2,000 tonnes, which can meet the needs of different project scales, whether it is a large-scale project or a small operation, you can find the right model.

5, flexible adjustment:

according to the material characteristics and needs, the teeth of the roll surface (such as serrated) and spacing adjustable to adapt to different sizes of crushing requirements