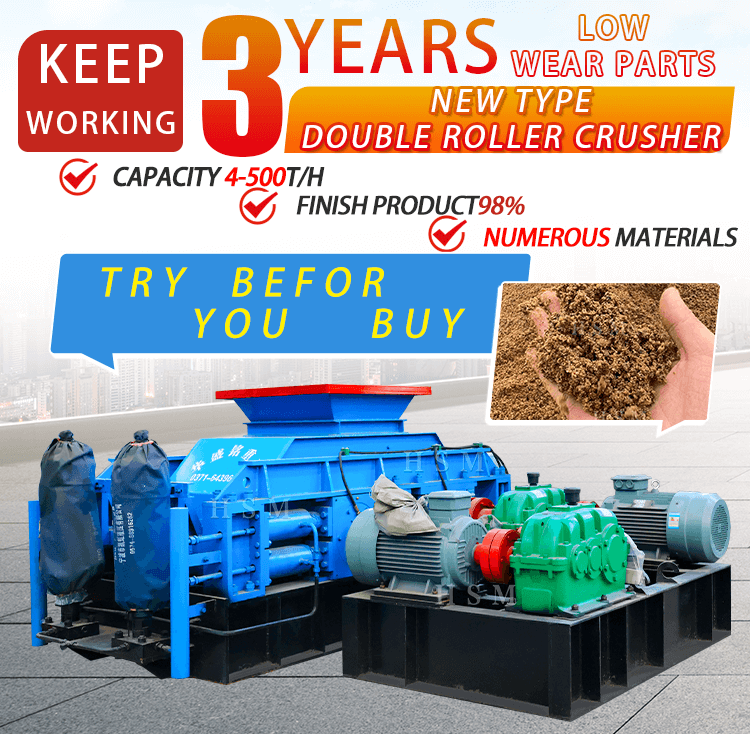

double roller crusher

Not all feed materials are ideal for direct processing in a sand making machine. Sticky clay, high-moisture content, or highly abrasive rock can cause inefficiency and increased wear. Implementing a roller crusher as a dedicated pre-processing unit provides an effective solution for these challenging conditions.

The roller crusher is particularly adept at handling slightly wet or cohesive materials that might clog other types of crushers. Its compression-based action can break apart clumps and reduce overall moisture content through mechanical action, creating a drier, more uniform feed. For your downstream sand making machine, this means smoother operation, significantly reduced risk of blockage, and protection for its wear parts. This approach allows you to utilize a wider range of raw materials without compromising your plant’s productivity or final sand quality.

Double Roll Crusher

Struggling with difficult raw materials? Discover how adding a specialized roller crusher stage can transform your sand production capability.