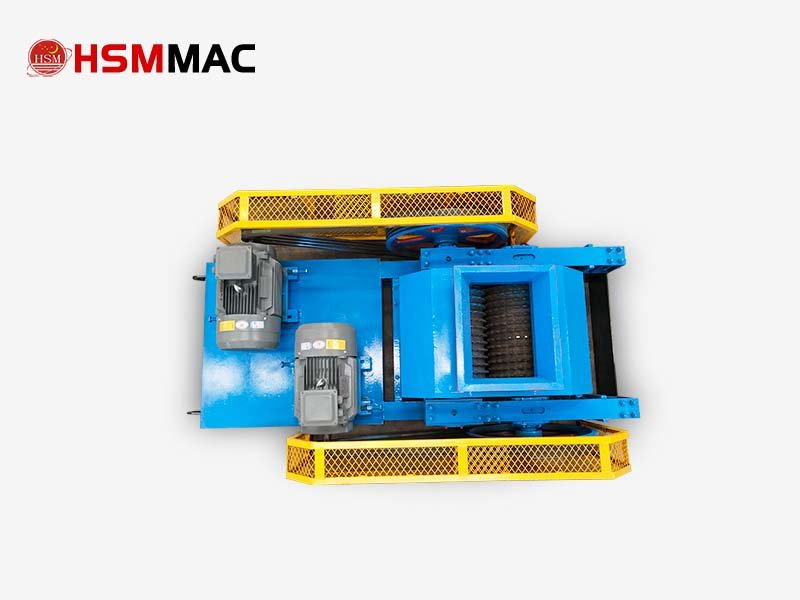

Huashengming’s small rock crusher primarily divided into two main categories: double-roll crushers and double-tooth roll crushers.

small rock crusher

1. Equipment Types and Core Models

Double Roll Crusher

Small Models: 250×250, 400×250, 400×400, 610×400

Production Capacity: 2-12 tons/hour

Applications: Fine crushing operations, output particle size 1-3mm (adjustable), suitable for sand plants and aggregate plants

Medium Models: 750×500, 800×600, etc. (Production Capacity: 20-50 tons/hour)

Double-Tooth Roller Crusher

Small Models: 2PGY750500, 2PGY800600, 2PGY1000700

Feed size: ≤40-60mm

Output size: 2-8mm (adjustable)

Production capacity: 15-60 tons/hour

Motor power: 18.5×2kW to 30×2kW

2. Technical Parameter Comparison (Primary Small Models)

| Model | Feed particle size (mm) | Discharge particle size (mm) | Production Capacity (t/h) | Motor Power (kW) | Weight (kg) |

| 400×400 Double Rollers | ≤5 | 1-3(adjustable) | 2-12 | 50 | Approx.5,000 |

| 610×400 Double Rollers | ≤50 | ≤5 | 20 | 400(dual motors) | 26,000 |

| 2PGY800600Toothed Rollers | ≤40 | 2-8(adjustable) | 25-40 | 22×2 | Approx.1,500 |

small rock crusher

3. Performance Advantages

High Efficiency & Energy Savings

Dual-motor drive design reduces energy consumption by 45% for equivalent output;

Low over-crushing rate with uniform particle size, ideal for high-hardness materials (e.g., river pebbles, granite).

Exceptional Durability

Roll shells utilize high-chromium manganese steel wear-resistant material, ensuring a service life exceeding 2 years (patent pending);

Integrated hydraulic spring design with overload protection minimizes wear part consumption.

Flexible Adjustment

Hydraulic system regulates roll gap for precise output particle size control (adjustable 1-10mm).

4. Application Scenarios & Materials

Suitable Materials: River pebbles, granite, basalt, limestone, coal gangue, construction waste, etc.

Application Fields:

Sand production in aggregate plants (fine crushing), medium crushing in mines, chemical raw material pulverization;

Construction waste recycling (e.g., crushing asphalt milled material).