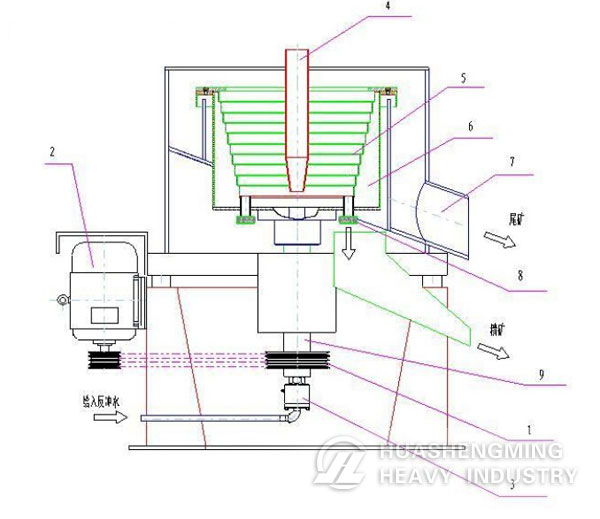

Gold Concentrator

| Application: | Alluvial gold, rock gold and other mineral concentrating. |

| Max feeding size: | 0-6 mm |

| Capacity: | 2-80 kg/time |

| Delivery: | 5-20 days |

| Shipment: | Accept EXW, FOB and CIF terms, by sea or by train. we have 20 years cooperate transport company. best freight, fast delivery. |

Skype: hsmzgcathy

Skype: hsmzgcathy  MSN: cnhsmzg@hotmail.com

MSN: cnhsmzg@hotmail.com Email: cnhsmzg@hotmail.com

Email: cnhsmzg@hotmail.com  Whatsapp: 008618339818180

Whatsapp: 008618339818180

- Technical Data

- Introduction

- Working Principle

- Inquiry

- Live Chat

Type |

STLB20 |

STLB30 |

STLB60 |

STLB80 |

STLB100 |

Capacity (T/h) |

0.2-1 |

2-8 |

10-40 |

35-70 |

75-120 |

Particle size (mm) |

0-3 |

0-4 |

0-6 |

0-6 |

0-6 |

Feeding |

0-50% |

0-50% |

0-50% |

0-50% |

0-50% |

Backwash water(T/h) |

1.5-2 |

4-6 |

10-15 |

17-25 |

40-60 |

Output (KG/TIMES) |

2-3 |

10-20 |

30-40 |

60-70 |

70-80 |

Power (kw) |

0.75 |

1.5 |

4 |

15 |

18.5 |

Revolution (r) |

800 |

600 |

460 |

400 |

360 |

Pressure |

0.04 |

0.12 |

0.4 |

0.4 |

0.6 |

Dimension (mm) |

930*700*900 |

1180*1140*1250 |

1970*1670*1750 |

2300*1800*2200 |

2500*2000 |

Weight (kg) |

205 |

400 |

1300 |

1500 |

2000 |

Please enter your demand such as Raw materials, Capacity(t/h,t/d), Materials feeding size(mm), Finial products size(mm) or other requirements