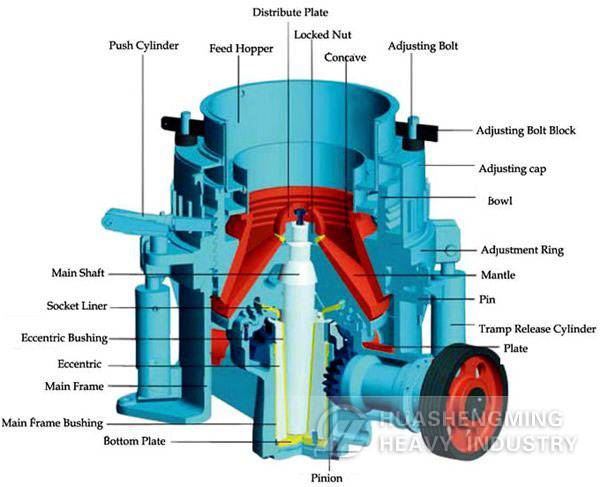

Hydraulic Cone Crusher

| Application: |

Hard and mid-hard rocks and ores like iron ore, copper, limestone, quartz and granite etc.

|

| Max feeding size: | 310 mm |

| Output size: | 5-60 mm |

| Capacity: | 12-1000 t/h |

| Delivery: | 5-15 days |

| Shipment: | Accept EXW, FOB and CIF terms, by sea or by train. we have 20 years cooperate transport company. best freight, fast delivery. |

Skype: hsmzgcathy

Skype: hsmzgcathy  MSN: cnhsmzg@hotmail.com

MSN: cnhsmzg@hotmail.com Email: cnhsmzg@hotmail.com

Email: cnhsmzg@hotmail.com  Whatsapp: 008618339818180

Whatsapp: 008618339818180

- Technical Data

- Introduction

- Working Principle

- Inquiry

- Live Chat

|

Model |

Chamber Size |

Max Feeding |

Adjusting Range of |

Capacity |

Motor |

Weight |

Overall Dimension |

|

HCC36B |

Fine |

85 |

9~22 |

46~94 |

75 |

14.2 |

2656×1746×2241 |

|

Coarse |

150 |

13-38 |

61~168 |

||||

|

Extra Coarse |

152 |

25-38 |

122~168 |

||||

|

HCC36D |

Fine |

35 |

3~13 |

28~93 |

14.7 |

||

|

Medium |

65 |

5~16 |

37~103 |

||||

|

Coarse |

85 |

6~19 |

61~133 |

||||

|

HCC51B |

Fine |

115 |

13~31 |

112~189 |

160 |

25.9 |

2983×2354×3156 |

|

Medium |

178 |

16~38 |

136~261 |

||||

|

Coarse |

205 |

19~51 |

177~359 |

||||

|

Extra Coarse |

220 |

25~51 |

243~369 |

||||

|

HCC51D |

Fine |

54 |

3~16 |

37~168 |

26.4 |

||

|

Medium |

76 |

6~16 |

84~168 |

||||

|

Coarse |

89 |

8~25 |

112~234 |

||||

|

Extra Coarse |

113 |

16~25 |

215~243 |

||||

|

HCC66B |

Fine |

178 |

16~38 |

186~337 |

220 |

50 |

3911×2870×3771 |

|

Medium |

205 |

22~51 |

266~430 |

||||

|

Coarse |

228 |

25~64 |

308~654 |

||||

|

Extra Coarse |

313 |

38~64 |

444~664 |

||||

|

HCC66D |

Fine |

60 |

5~13 |

93~215 |

51 |

||

|

Medium |

76 |

6~19 |

140~289 |

||||

|

Coarse |

113 |

10~25 |

196~346 |

||||

|

Extra Coarse |

125 |

13~25 |

261~346 |

||||

|

HCC84B |

Fine |

236 |

19~38 |

392~748 |

315 |

88 |

4613×3302×4638 |

|

Medium |

284 |

25~51 |

626~1028 |

||||

|

Coarse |

314 |

31~64 |

813~1308 |

||||

|

Extra Coarse |

391 |

38~64 |

906~1402 |

||||

|

HCC84D |

Fine |

89 |

5~16 |

196~420 |

90 |

||

|

Medium |

113 |

10~19 |

365~523 |

||||

|

Coarse |

151 |

13~25 |

468~617 |

||||

|

Extra Coarse |

172 |

16~25 |

523~673 |

Please enter your demand such as Raw materials, Capacity(t/h,t/d), Materials feeding size(mm), Finial products size(mm) or other requirements