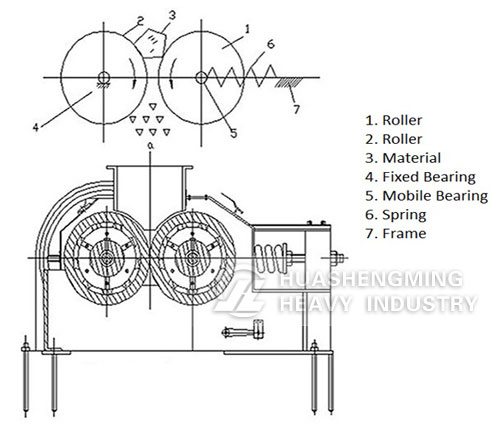

Roller Crusher

| Application: | Ore crushing, chemical industry, cement production, silicate production, coal crushing, refractory, abrasive and construction industries. |

| Max feeding size: | 150 mm |

| Output size: | 0-5 mm |

| Capacity: | 2-140 t/h |

| Delivery: | 5-15 days |

| Shipment: | Accept EXW, FOB and CIF terms, by sea or by train. we have 20 years cooperate transport company. best freight, fast delivery. |

|

|

|

Skype: hsmzgcathy

Skype: hsmzgcathy  MSN: cnhsmzg@hotmail.com

MSN: cnhsmzg@hotmail.com Email: cnhsmzg@hotmail.com

Email: cnhsmzg@hotmail.com  Whatsapp: 008618339818180

Whatsapp: 008618339818180

- Technical Data

- Introduction

- Working Principle

- Inquiry

- Live Chat

|

Model |

Feeding size |

Discharging size(mm) |

Capacity |

Motor power |

Weight |

Dimension |

|

2PG400×250 |

<35 |

≤2-8 |

2-10 |

2×5.5 |

1.3 |

2110×870×810 |

|

2PG610×400 |

<65 |

≤2-20 |

5-20 |

2×15 |

3.9 |

3510×1420×1030 |

|

2PG750×500 |

<75 |

≤2-25 |

10-40 |

2×18.5 |

9.5 |

4210×1630×1260 |

|

2PG800×600 |

<80 |

≤2-25 |

12-45 |

2×22 |

10.8 |

4505×1780×1320 |

|

2PG1000×700 |

<100 |

≤3-30 |

20-65 |

2×30 |

14.9 |

5310×2175×1595 |

|

2PG1200×800 |

<120 |

≤3-35 |

35-80 |

2×37 |

25.5 |

6290×2270×1870 |

|

2PG1500×800 |

<130 |

≤3-45 |

50-120 |

2×75 |

33.7 |

7460×2410×2290 |

|

2PG1600×1000 |

<150 |

≤3-50 |

60-140 |

2×90 |

41.2 |

8220×2680×2475 |

Please enter your demand such as Raw materials, Capacity(t/h,t/d), Materials feeding size(mm), Finial products size(mm) or other requirements