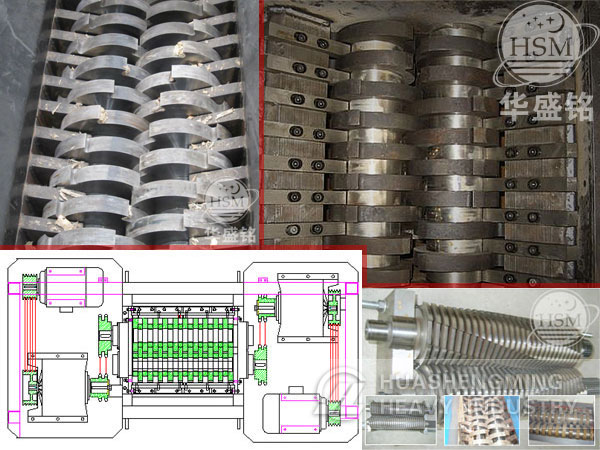

Double Shaft Shredder

| Application: | Shredding plastic, rubber, fiber, paper, wood, car tyre, TV, large hollow materials, such as plastic buckets and some other large vessel, all kinds of combined waste materials, especially those with metals, or worn cutting tools. |

| Max feeding size: | 1000 mm |

| Output size: | 0-20 mm |

| Capacity: | 0.5-30 t/h |

| Delivery: | 5-15 days |

| Shipment: | Accept EXW, FOB and CIF terms, by sea or by train. we have 20 years cooperate transport company. best freight, fast delivery. |

|

|

|

Skype: hsmzgcathy

Skype: hsmzgcathy  MSN: cnhsmzg@hotmail.com

MSN: cnhsmzg@hotmail.com Email: cnhsmzg@hotmail.com

Email: cnhsmzg@hotmail.com  Whatsapp: 008618339818180

Whatsapp: 008618339818180

- Technical Data

- Introduction

- Working Principle

- Inquiry

- Live Chat

|

|

Model |

Power |

Capacity |

Shear Knife |

Feeding Size |

|

Shear Knife |

SX—500 |

7.5 |

300-600 |

16 |

680*760 |

|

SX—600 |

11 |

400-800 |

24 |

840*760 |

|

|

SX—800 |

22 |

600-1000 |

32 |

1000*760 |

|

|

SX—800(big) |

15*2 |

700-1200 |

32 |

1000*760 |

|

|

SX—1000 |

22*2 |

800-1500 |

40 |

1160*760 |

|

|

Shear Knife |

SX—600 |

15 |

500-1000 |

12 |

850*990 |

|

SX—800 |

15*2 |

800-1200 |

16 |

1010*990 |

|

|

SX—1000 |

18.5*2 |

1000-1500 |

20 |

1170*990 |

|

|

SX—1200 |

22*2 |

1500-2000 |

26 |

1410*990 |

|

|

SX—1500 |

30*2 |

2000-2500 |

38 |

1890*990 |

|

|

Shear Knife |

SX—600 |

15 |

800-1000 |

12 |

850*1090 |

|

SX—800 |

18.5*2 |

1000-1500 |

16 |

1010*1090 |

|

|

SX—1000 |

18.5*2 |

1500-2000 |

20 |

1170*1090 |

|

|

SX—1200 |

22*2 |

2000-2500 |

26 |

1410*1090 |

|

|

SX—1500 |

30*2 |

2200-3000 |

38 |

1890*1090 |

Please enter your demand such as Raw materials, Capacity(t/h,t/d), Materials feeding size(mm), Finial products size(mm) or other requirements