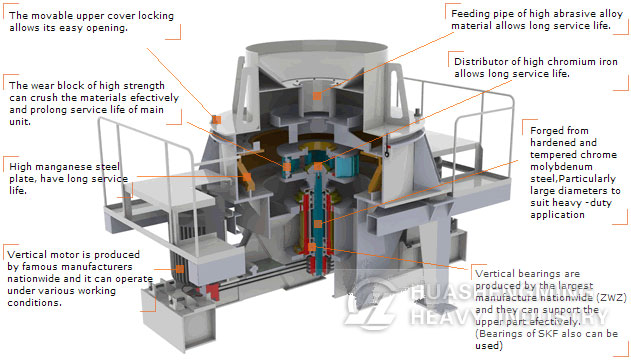

VSI Vertical Shaft Impact Crusher

| Application: |

River stone, mountain stone, ore tailings, aggregate chips, sand making and rock reshaping etc.

|

| Max feeding size: | 30-50 mm |

| Output size: | 0-5 mm |

| Capacity: | 120-600 t/h |

| Delivery: | 5-15 days |

| Shipment: | Accept EXW, FOB and CIF terms, by sea or by train. we have 20 years cooperate transport company. best freight, fast delivery. |

Skype: hsmzgcathy

Skype: hsmzgcathy  MSN: cnhsmzg@hotmail.com

MSN: cnhsmzg@hotmail.com Email: cnhsmzg@hotmail.com

Email: cnhsmzg@hotmail.com  Whatsapp: 008618339818180

Whatsapp: 008618339818180

- Technical Data

- Introduction

- Working Principle

- Inquiry

- Live Chat

|

Model |

VSI-7611 |

VSI-8518 |

VSI-9526 |

VSI-1140 |

VSI-1145 |

|

|

Capacity (t/h) |

Cascade and |

120-180 |

200-260 |

300-380 |

450-520 |

490-600 |

|

Center feeding |

60-90 |

100-130 |

150-190 |

225-260 |

250-310 |

|

|

Feeding size |

Soft material |

0-35 |

0-40 |

0-45 |

0-50 |

0-50 |

|

Hard material |

0-30 |

0-35 |

0-40 |

0-45 |

0-45 |

|

|

Rotation Speed (r/min) |

1700-1890 |

1520-1690 |

1360-1510 |

1180-1310 |

1180-1280 |

|

|

Power of the Double |

110-150 |

180-220 |

264-320 |

400-440 |

440-520 |

|

|

Overall Dimension (mm) |

3700X2150 |

4140X2280 |

4560X2447 |

5000X2700 |

5100X2790 |

|

|

Weight(T) |

9.8 |

13.5 |

16.8 |

25.6 |

27.5 |

|

|

Power |

380v:50Hz, can adjust |

|||||

|

Vibrating Sensor |

Inspection scope: 0.1-2mm/s, it can be adjusted continuously |

|||||

|

Hydraulic |

Power of double |

2x0.31Kw |

||||

|

Safety |

Double oil pumps make sure supply of oil; stope automatically without oil |

|||||

|

Overall Dimension |

820*520*1270 |

|||||

|

Power of oil-box heater |

2KW |

|||||

Please enter your demand such as Raw materials, Capacity(t/h,t/d), Materials feeding size(mm), Finial products size(mm) or other requirements