1. Mobile Crusher

Feed Size: 25-100mm

Production Capacity: 2-400 t/h

Suitable Materials:

River pebbles, calcite, quartzite, marble, stone, bentonite, iron ore, bluestone, quarry rock, slag, limestone, weathered sand, diabase, granite, basalt, etc.

Mobile Crusher Applications:

Highways, high-speed railways, high-rise buildings, municipal projects, hydroelectric dam construction, concrete batching plants, sand and gravel yards, etc.

2. Application Scope:

Mobile Crusher

Mobile double-roll crushers can be customized with primary, secondary, tertiary crushing, and screening equipment based on client requirements. They can be configured as “crush-then-screen” or “screen-then-crush” processes according to specific crushing needs, with crushing and screening units also operable independently. The crushing station can be configured into a two-stage coarse/fine crushing and screening system or a three-stage coarse/medium/fine crushing system based on actual requirements.

3. Applicable Materials

Suitable for crushing and sand-making operations on materials such as river pebbles, calcite, quartz, glass, marble, cobblestones, bentonite, iron ore, bluestone, mountain rock, limestone, weathered sand, diabase, granite, and basalt.

Mobile Crusher

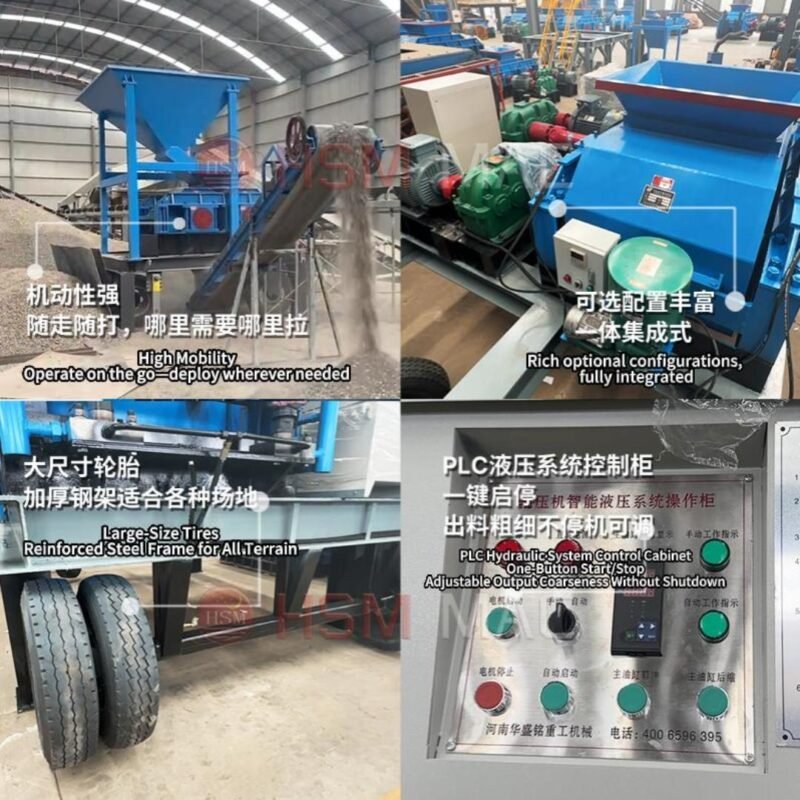

4. Actual Photos

Brand-new equipment with complete model range

Mobile Crusher

5. Working Principle

During operation, the mobile double-roll crusher coordinates feeding, crushing, and screening equipment. Materials first enter the crushing section for processing, followed by sand-making and screening. Only qualified particles proceed to the sand-making machine for further processing. Qualified finished products are discharged via the discharge device, while non-compliant material is returned for reprocessing.

6. Performance Advantages

Mobile Crusher

1. Integrated unit installation eliminates complex site infrastructure work for separate components, reducing material handling time. The compact, rational spatial layout enhances site deployment flexibility.

2. High mobility and flexibility. This saves time for rapid site access, facilitates deployment in optimal construction zones, and provides greater spatial flexibility and rational layout configuration for the entire crushing process.

3. The integrated mobile double-roll crusher can operate independently or be flexibly configured to meet customer requirements for material types and product specifications within the process. It fulfills diverse needs such as mobile crushing and screening, streamlining production logistics and significantly reducing costs.

7. Shipping Site

On-site Shipping | Trustworthy

Mobile Crusher