Huashengming’s “rubble master crusher” series excels in construction waste recycling, sand and gravel aggregate production, and specialized solid waste treatment through wear-resistant design, intelligent control, and scenario adaptability.

rubble master crusher

1. Construction Waste Recycling (Municipal Road Construction)

Case Background: During the West Ring South Street road expansion project, Cangzhou Municipal Engineering Company needed to demolish four 6-story buildings. The tight schedule and high construction waste disposal costs posed significant challenges.

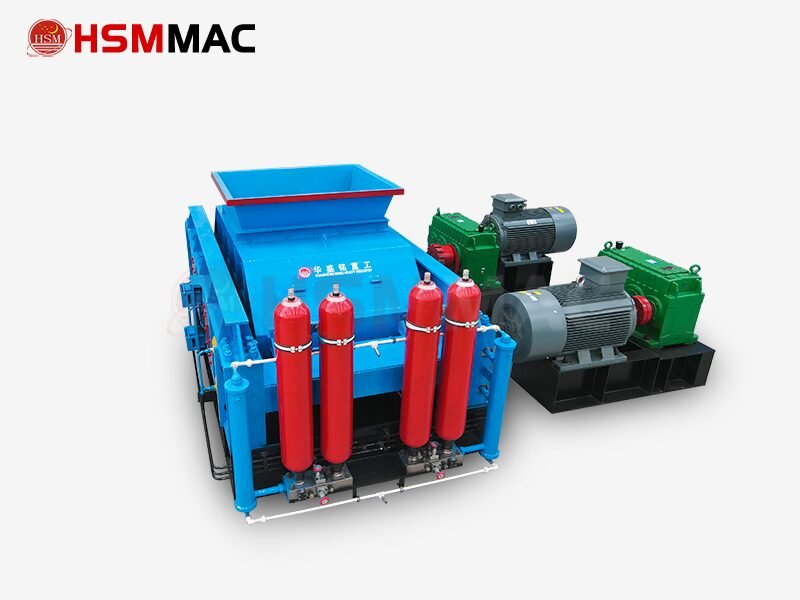

Equipment Solution: Employed a double-roll crusher with “Rock Master” functionality (reference model: 2PGY series) for on-site construction waste processing.

Application Outcomes:

Resource Recovery:

Reached 95% rebar separation recovery rate. Crushed bricks, tiles, and concrete aggregates (≤12mm particle size) were directly used for road subbase, reducing new material procurement costs by 30%.

Reduced waste removal fees and landfill space, lowering overall project costs by 25%.

Environmental Efficiency:

Built-in dust control system maintains PM10 concentrations below standards (50μg/m³) in construction zones, with noise levels under 85dB, meeting urban construction requirements.

Mobility Advantage:

Hydraulic chassis enables flexible relocation; equipment assembly/disassembly completed within 3 hours, adapting to confined demolition sites.

2. Efficient Sand and Gravel Production Line (Medium-Sized Quarry)

Case Background: Shandong Yongchang Stone Co., Ltd. required a 200-ton-per-hour river pebble crushing line with high-quality finished product shape and low needle/flake content.

Equipment Solution: A three-stage crushing system comprising a jaw crusher (primary crushing) + cone crusher (secondary crushing) + Huashengming impact crusher (tertiary crushing).

Application Results:

Improved Product Quality:

Impact crusher (referencing CH series) produces ≤6mm output with <5% needle/flake content, exceeding national standards (≤10%). Output serves as high-grade concrete aggregate.

Optimized Capacity & Energy Consumption:

Production line operated continuously for 3 years without major repairs. Unit energy consumption reduced by 15% compared to traditional equipment. Wear parts lifespan extended to 18 months.

Environmental Compliance:

With integrated dust collection equipment, dust emission concentration <20mg/m³, meeting green mining standards.

3. Special Material Processing (Oilfield Solid Waste Resource Recovery)

Case Background: The mudstone recovery project at Aksu Oilfield in Xinjiang requires processing high-moisture, impurity-laden mudstone waste at a rate of 100 tons per hour.

Equipment Solution: Utilizes Huashengming’s double-stage screenless crusher (refer to SCF series) as the main unit, equipped with a magnetic separator and screening system.

Application Results:

Anti-clogging Design:

Screenless structure + dual-rotor crushing enables clog-free processing of sticky mudstone with 15% moisture content, achieving continuous operation with <1% failure rate.

Precision Output:

Final product size ≤6mm (80% ≤2mm), directly used for oilfield roadbed filling with over 90% resource recovery rate.

Economic Benefits:

Compared to purchased sand and gravel, cost reduction of ¥40 per ton; annual processing of 100,000 tons of mudstone saves ¥4 million.

rubble master crusher

4. Energy Efficiency and Cost-Benefit Comparison

| Application Scenarios | Traditional Equipment | Crusher Master Solution | Efficiency Enhancement |

| Construction Waste Processing (Cangzhou) | Haulage + Landfill, Cost: ¥180/ton | On-site crushing, cost: 60 yuan/ton | ↓67% Cost Reduction, ↑30% Resource Utilization |

| River Pebble Sand Making (Shandong) | Impact Crusher + Ball Mill, Power Consumption: 8kWh/ton | Three-stage impact crushing, power consumption: 6.8 kWh/ton | ↓15% Energy Consumption, ↑20% Production Capacity |

| Oilfield Mud and Rock Processing (Xinjiang) | Sorting + Off-site Haulage, No Resource Recovery | Full-process recycling, producing aggregate | Annual Savings of 4 Million, ↑90% Resource Recovery Rate |