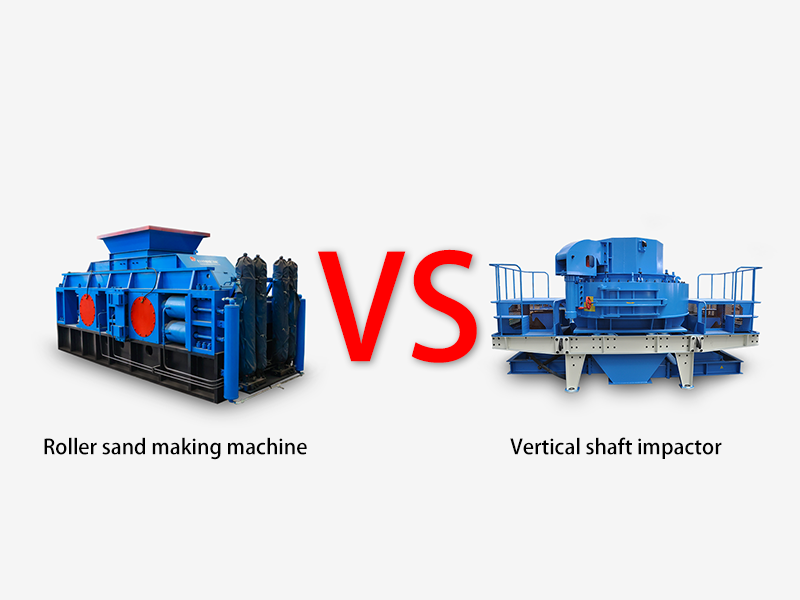

Roller sand making machine has the following advantages compared with vertical shaft impactor in terms of finished product rate:

1. Higher and stable yield of roll sand making machine

The product yield of Roller Sand Making Machine is usually close to 100%, especially after plastic crushing, there is almost no material waste. Its double-roll extrusion design reduces ineffective crushing and over-crushing by precisely controlling the material crushing process. The yield of vertical shaft impact crusher is greatly affected by the hardness of raw materials and the performance of the equipment, which is generally 60%-85%, and may even be as low as 30%-40% when dealing with hard rocks (e.g. basalt).

2. Lower energy consumption and operating costs

Roller sand making machine has a simple structure, less energy loss in the crushing process, and the power consumption and operation cost per unit of product are significantly lower than that of vertical shaft impact crusher (estimated operation cost is 1-2 USD/tonne, while that of vertical shaft impact crusher is 2-3 USD/tonne). Vertical shaft impact crusher needs supporting vibrating screen, elevator and other equipment, the system is complex and high energy consumption.

3. Strong adaptability and low maintenance cost

Roller sand making machine can flexibly control the size of finished products by adjusting the roller spacing, which is suitable for medium-hard and soft ores, and the wear-resistant roller skin design reduces the replacement frequency of wear parts. Vertical shaft impact crusher in the processing of high hardness materials, rotor wear faster, higher maintenance costs, and need to frequently adjust the equipment parameters to cope with different raw materials.

4. Reduce the problem of over-crushing

Roller sand making machine through extrusion crushing rather than high-speed impact, effectively reduce the excessive generation of stone powder, the finished sand in the stone powder content is more controllable. Vertical shaft impact crusher’s ‘stone hitting stone’ principle easily leads to the proportion of fine powder is too high or insufficient, and additional equipment (such as powder selector) is needed to adjust the content of stone powder.

Roller sand making machine has significant advantages in yield, cost control and maintenance convenience, which is suitable for projects sensitive to sand production and cost; while vertical shaft impactor is more suitable for scenarios with high requirements on sand grain shape and quality, but needs to accept lower yield and higher operation investment.