The working principle of the hydraulic double roll crusher is based on the double-roll compression crushing mechanism, combined with the intelligent control of the hydraulic system, to achieve efficient and precise material crushing.

1. Core crushing principle of the hydraulic double-roll crusher: double-roll compression and multi-force synergy

hydraulic double roll crusher

Material crushing process

Feeding and feeding: Material enters the crushing chamber through a feeding device (vibrating feeder or belt conveyor) and falls onto the two parallel cylindrical rolls.

Squeezing and Crushing: The rollers rotate in opposite directions. Under the combined effects of friction force on the roller surface and the material’s own gravity. The material is drawn into the roller gap, subjected to multiple forces such as squeezing, shearing, and kneading. When the external force exceeds the material’s crystal lattice cohesive force. The material is crushed to the target particle size.

Discharge Control: The crushed material is discharged through the roller gap, falls downward into the discharge device, and proceeds to the next processing stage.

Source of Crushing Force

The roller surfaces are typically covered with high-manganese steel or chromium-molybdenum alloy roller liners. Which offer excellent wear resistance and require no replacement throughout their service life (traditional equipment requires annual replacement).

The roller gap range is adjustable (1–40 mm), accommodating different particle size requirements (e.g., construction sand requires ≤3 mm, road base material requires 8–16 mm).

2. The Key Role of the Hydraulic System in Double Roll Crushers

Precise Roll Gap Adjustment

The hydraulic cylinder moves the movable roll via a piston, adjusting the gap between the two rolls in real time (with precision up to ±0.1mm), ensuring output particle size deviation ≤3%.

For example: when processing granite, a smaller gap (1–5mm) is set for sand production. When processing roadbed material, a larger gap (8–16mm) is set.

Overload Protection and Stability

Automatic Avoidance of Hard Objects: When non-crushable materials such as metal enter the system. The hydraulic system instantly increases the roll gap to expel the foreign object, then automatically restores the set gap to prevent equipment damage.

Pressure Maintenance: The accumulator (filled with nitrogen, pressure 6–8 MPa) stabilises system oil pressure (working pressure 10 MPa). Cushions impact forces, and ensures continuous operation.

Power Transmission and Energy Saving

The hydraulic motor drives the rollers to rotate, offering high torque and fast response. Achieving 20%–30% energy savings compared to mechanical transmission (specific power consumption: 0.8–1.2 kWh/ton).

The system dynamically adjusts power to reduce idle energy consumption, such as automatically reducing pressure during standby.

3. Typical Application Scenarios

Mining and Metallurgy: Crushing granite and iron ore (compressive strength ≤ 250 MPa), producing 1–5 mm mechanically produced sand.

Construction Waste Recycling: Screenless design prevents clogging, processing concrete blocks with moisture content ≤ 35%, producing recycled aggregate ≤ 3 mm.

Chemical Industry: Precisely controlling the particle size of sulphur and fertiliser raw materials, with a sealed structure to prevent dust pollution.

Road Construction: Preparation of asphalt aggregate (3–5 mm), with a cubic particle ratio ≥95%, enhancing road surface strength.

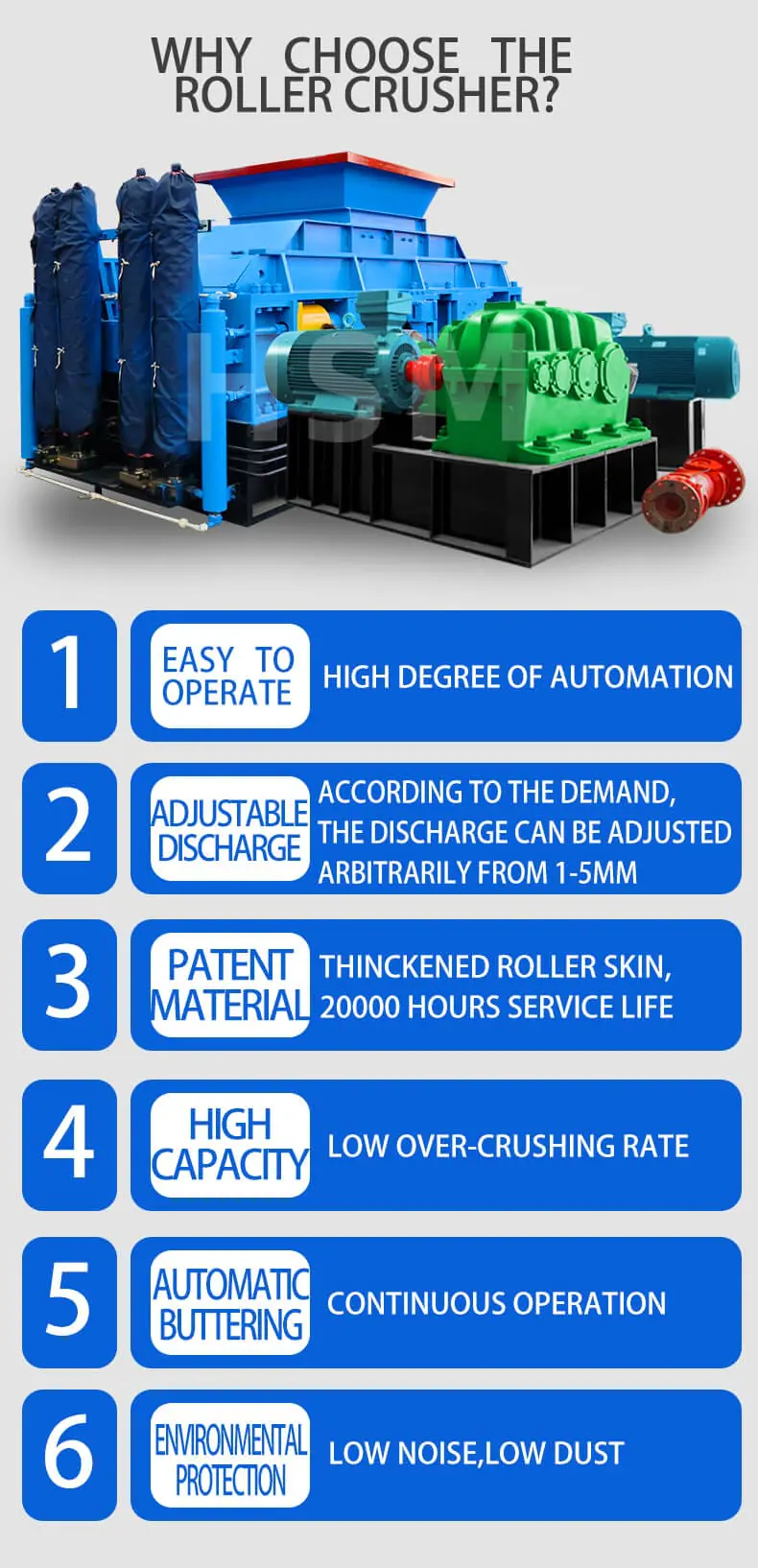

The hydraulic double-roll crusher achieves three major breakthroughs through the ‘intelligent hydraulic control + dual-roll collaborative crushing’ mechanism:

Precision and Efficiency: Dynamic adjustment of particle size, with a 30%–40% increase in production capacity (e.g., the 2PGY1510 model achieves 150 tonnes per hour);

Safety and durability: overload protection + lifetime rollers, reducing failure rate by 40%;

Energy efficiency and environmental protection: 20% reduction in energy consumption per unit, 70% reduction in dust leakage (sealed dust-proof plate design), noise level ≤85dB.

Manufacturer recommendations: Hongxing Machinery (intelligent control system), Huashengming Heavy Industry (dual-stage screenless anti-blocking model), with customizable corrosion-resistant/explosion-proof designs available.