What is a four-roll crusher? The roller crusher (also known as a double-roll crusher or twin-roll crusher) is a mechanical device that utilizes two counter-rotating rollers to crush materials through compression, grinding, or splitting. It is primarily used for medium and fine crushing of materials of medium hardness or below, such as coal, limestone, and ores.

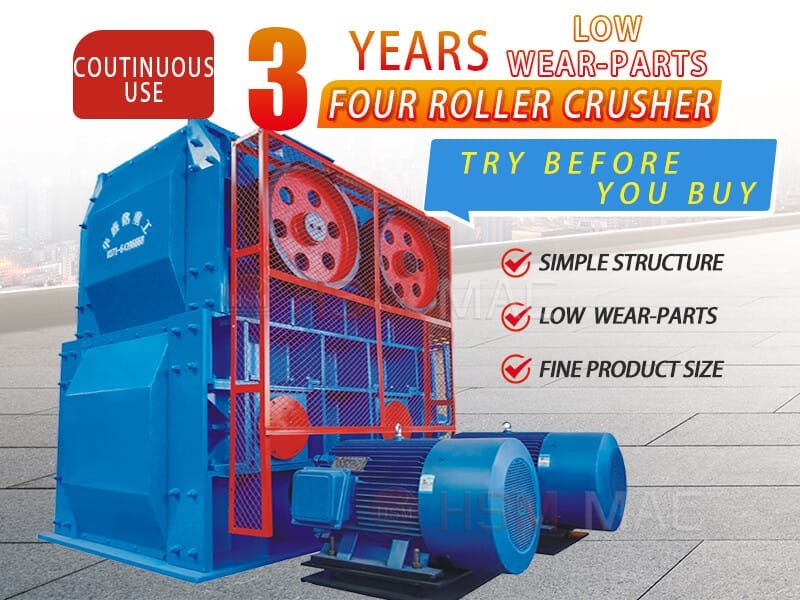

four roll crusher

1. Definition and Core Principles of Roller Crushers

Working Principle

Material enters through the feed opening and falls between two rollers. Driven by the friction generated from the rotating rollers, it is drawn into the crushing chamber where it is broken down through compression, shearing, or splitting forces. The discharge particle size is controlled by adjusting the gap between the two rollers (1–20 mm); a larger gap produces coarser output.

Overload Protection:

When hard objects enter, springs or hydraulic systems retract the movable roll to widen the gap, expelling foreign matter before automatically resetting.

Drive Configuration:

Dual motors drive the two rolls in opposite directions via belts or gears. Traditional models use long-tooth gears to accommodate varying roll distances.

Roller Surface Types and Applications

Smooth Rollers:

Primarily for compression grinding, suitable for fine crushing of medium-hard materials (e.g., limestone, cement clinker).

Toothed/Grooved Rollers:

Enhance splitting action, ideal for coarse crushing of brittle materials like coal and coke, reducing over-crushing.

2. Types and Structural Features

Classified by Number of Rollers

Double-roll crushers: Most common, available in smooth or toothed versions, with capacities ranging from 2 to 400 tons per hour.

Four-roll crushers: Composed of two pairs of double rolls, used for high-precision fine crushing (e.g., coal classification crushing).

Single-roll crushers: Less common, suitable for specific coarse crushing applications.

Core Structural Components

Rollers and Wear-Resistant Liners: High-manganese steel or high-chromium alloy roller skins with a lifespan of 1–3 years (Huashengming’s patented material extends this to over 2 years).

Adjustment Mechanisms:

Spring-loaded mechanical: Manual shim adjustment for gap regulation, low cost.

Hydraulic automatic: One-button adjustment with high precision (standard on Huashengming mid-to-high-end models).

Safety Device: Overload protection via spring or hydraulic system.

3. Application Scenarios & Core Advantages

Suitable Industries & Materials

Mining: Fine crushing of iron ore and quartzite, reducing ball mill energy consumption by 30%-50% (“more crushing, less grinding” principle).

Building Materials: Sand production from river pebbles and granite, producing uniform 1–3mm output particle size.

Coal/Environmental Protection: Crushing raw coal (including gangue) and construction waste without pre-decontamination, simplifying processes.

Chemical/Metallurgical: Medium-fine crushing of limestone, coke, and feldspar.

Advantages & Features

Low over-crushing rate: Extrusion crushing minimizes powdery waste, enhancing finished product utilization.

Energy-efficient: 30%-50% lower energy consumption per unit compared to impact crushers, with power consumption of 1–2 kWh per ton of material.

Easy maintenance: Modular design facilitates quick replacement of wear parts (e.g., Huashengming roller liners can be rapidly disassembled).

4. Product Features and Models of Huashengming Double Roll Crushers

Core Technical Advantages

Patented Wear-Resistant Roll Shell: High-chromium manganese steel + rare metal alloy, 2–3 year lifespan, compressive strength ≤160MPa.

Intelligent Hydraulic System: One-button gap adjustment (1–20mm), integrated automatic lubrication and remote monitoring (large models).

High Adaptability: No clogging with wet materials, no jamming with dry materials, stable operation even at moisture content ≤35%.