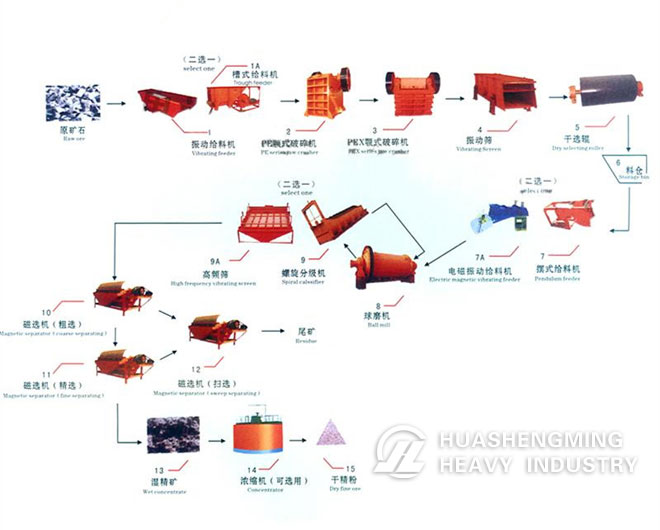

Magnetic Separation Process

Introduction:

Magnetic separator is mainly used for separation. when mineral particles and ore particles into the magnetic separator, because of the different magnetic, under the effect of magnetic field, the magnetic particles enter into the concentration pool, non-magnetic mineral grains into the tailings ponds.

Application:

Magnetic separation method is widely used in ferrous metal ore sorting, selection of the nonferrous and precious metal ore, recovery and purification of heavy media separation of magnetic medium, etc Processing magnetite can effectively improve the ore grade, according to different requirements can get 30-55% of iron essence pink.

Equipments:

Crusher, ball mill, spiral classifier, magnetic separator.

Mining ores are first crushed to a reasonable fineness by crusher, and then fed into the ball mill evenly by elevator and feeder. Ball mill crushes and grinds ores. The fine ore powder grinded by ball mill will enter into next process-classification. According to the principles that different proportion of solid particles precipitated in the liquid velocity, spiral classier will clean and classify mineral mixture. the mixture was washed ore, grading. Because different minerals different susceptibility , the magnetic material will be separated by magnetic mechanical force from the washed and graded mineral mixture when they are passing through magnetic separator.